I received a lot of feedback on last week’s Code Compliance Villains, which described blunders that occurred as part of my high-efficiency boiler installation. Such mistakes would likely erode 50% of the estimated savings claimed in a deemed savings document. Efficiency issues included:

- Improper outdoor temperature sensor location giving false inputs to the controls.

- High boiler water temperature setpoints resulting in lower operating efficiency.

- Heat exchanger piped in parallel, rather than counterflow, resulting in higher boiler water temperatures and less efficiency.

The problem with efficient equipment and energy codes is that equipment is tested in the lab, and hands are washed once the test results are complete. As described above and in more detail in recent posts here and here, efficiency benefits are easily decimated when installing equipment into a system and controlling it. As for control systems, they are built on-site and tested for functionality, but rarely for system efficiency. I.e., control systems have even less chance of code compliance without lab testing.

Contractor Issues

I love talking with HVAC and controls contractors. They are smart, resilient, hardworking, and take tremendous pride in their creations – just like the beautiful piping job on my boiler before it had to be torn apart and reconnoitered.

However, I sense two things. First, many/most contractors take efficiency for granted and trust the cookbook controls setup too much. Second, they don’t understand the fundamental physics of the equipment they are installing – e.g., efficiency performance curves versus firing rate and return water temperature. But then, circling back to the handwashing, manufacturers don’t even supply these data.

From the start of my boiler project, understanding how complicated temperature reset, boiler firing rate, and variable speed pumping is to sequence (control), I asked, “Aren’t you going to show me how all this stuff is controlled?” Apparently not, and in fact, not. By self-learning, I have the boiler and reset mastered, but I have no idea how the variable speed pump is controlled.

Energy Efficiency Code Issues

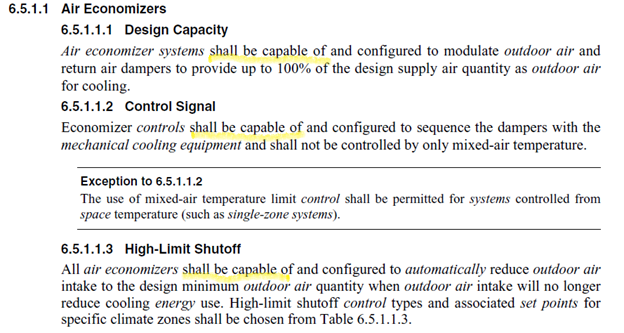

Energy codes use language such as “shall be capable” dozens, if not hundreds of times. To wit, an excerpt from ASHRAE 90.1-2019, Energy Standard (Code) for Commercial Buildings:

The word capable appears 46 times in the HVAC system section alone, and that does not count all the equipment efficiencies. For example, my boiler is capable of 95% seasonal efficiency, but that will not be achieved with excessively high-water temperatures, a misplaced outdoor air temperature sensor, and a backward-plumbed heat exchanger. Think about that. Every prescribed requirement for heating and cooling efficiency is only the capability to deliver.

The word capable appears 46 times in the HVAC system section alone, and that does not count all the equipment efficiencies. For example, my boiler is capable of 95% seasonal efficiency, but that will not be achieved with excessively high-water temperatures, a misplaced outdoor air temperature sensor, and a backward-plumbed heat exchanger. Think about that. Every prescribed requirement for heating and cooling efficiency is only the capability to deliver.

Imagine applying capable to your kids or your pet. Your kid shall be capable of taking out the trash. Your kid shall be capable of picking up their room. Your dog shall be capable of doing its business outside. These are quite meaningless, are they not?

Pride

Some people live for being right all the time. As demonstrated by writing this blog every week, that would not be me. To be right all the time is not to be vulnerable, nor does it move the ball down the field. Football coaches almost always choose to be right rather than be vulnerable and win. They’d rather sluff pressure off the kicker and go for three rather than seven. They fear being wrong. If the kicker blows it, it’s the kicker’s fault. It sucks to be a kicker.

Systems design, controls, and installation follow similar paths – belt, suspenders, and another belt, just to be sure. Nobody wants to be called back for comfort issues – that is the number one objective. They must be right on that, and efficiency? I don’t blame them. Contractors won’t be embarrassed if a system uses 25% more energy than it should, but they will be if the thermostat doesn’t control temperature. I think my boiler technicians were embarrassed by those things, but I think they were ticked off when I told them the heat exchanger was installed backward. Why? Because it worked as installed. What is your problem? Efficiency is my problem.

Energy Codes and Efficiency Programs

As demonstrated in these recent three posts, code officials may be able to verify 20% of as-built code compliance as it impacts energy consumption. Compliance requires equipment operation, systems, controls expertise, and a lot of time on-site digging for issues and fixing them. NOW, THEREFORE,

- Energy codes are merely aspirations.

- Assuming such aspirations are met is laughable.

- Using codes as baselines is wrong.

The efficiency industry strands thousands of gigawatt hours of savings because of specious beliefs in energy code gods. New construction programs that scrap for crumbs of savings from features that purportedly exceed code would capture more savings by ensuring systems are built and controlled efficiently, rather than merely having capabilities on paper.

Consider the leverage of such a program. For example, how many heat exchangers have been installed backward like mine was? Catching that once and explaining it contractor-wide may fix the problem for dozens more going forward. I think that’s called market transformation.

Attribution?

Finally, for evaluators, the almighty Uniform Methods Project defines net savings (attribution) as follows: “The difference in energy consumption with the program in place versus what consumption would have been without the program in place.”

It does not say, “…versus what consumption would have been under code compliance.” Therefore, why in the PG-rated hell are energy codes always used as baselines?

It is time to change.