In case you missed last week’s post, you’ll need to go back and review the setup for this week’s demonstration of code challenges and mistakes. To summarize, I have an installed ENERGY STAR-qualifying 95% AFUE[1] (efficient) boiler with a brazed plate heat exchanger, hot water reset control, and a variable firing rate that ranges from 20% to 100%. That firing range is even better than code requirements. The system is a duded-out energy code breaker in theory. Let’s look at what went wrong in order.

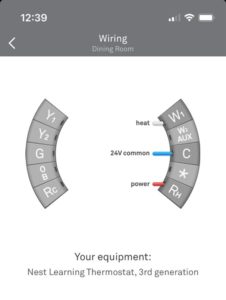

I have a Nest cam in the backyard and a Nest thermostat for the boiler. I knew the crew was finished when they were no longer coming and going. I checked my thermostat. It was offline. Why? I don’t know, so I drove home and found that the battery had lost too much juice from the ~28 hours of not being connected to low-voltage power from the boiler. Ok. I charged that for a couple of minutes and put it back on the wall. It seemed to be working fine. It was about 68F in the space, and the boiler was still firing.

Thermostat Problem

I went back to the office, and I noticed the home temperature kept rising. What is going on? It was set to 68°F, and the boiler is still firing. It’s 71°F. It’s 73°F. What the hell? The thermostat is connected and powered just like before, but it’s not telling the boiler to shut off.

Installation concluded at noon Friday, so all weekend, I controlled the temperature in my house with the water temperature from the boiler. This is like riding a bike or driving a car with no brakes. You can do it, but it’s not easy. It’s slow and takes patience.

The installers had programmed the boiler for a design-day (coldest weather) water temperature of 160°F. As noted last week, I trimmed that back to 140°F to save energy. However, without a thermostat controlling, I set it lower per the following reset scheme.

Outdoor Temperature Sensor Problem

Outdoor Temperature Sensor Problem

I was getting by without the thermostat until the afternoon. As I sat in my Le Corbusier in the living room, where I draft 90% of Rants, I noticed, gee, it’s getting a mite chilly in here. What’s going on? I went downstairs to check the control panel on the boiler. It said it was 44°F outside. What? I have two weather apps on my phone and Alexa. “Alexa, what’s the temperature?” “Right now, it’s 15 degrees Fahrenheit. Tonight, you can expect, [blah blah].” “Alexa, put a sock in it.”

In about 10 seconds, I thought, “Where did they put the outdoor temperature sensor?” I found it on the south face of the house, where it catches the afternoon sun once it clears the neighbor’s home’s shadow around 1:00 PM. Bonk! The sensor tells the boiler it’s 44°F, and the boiler’s logic says the target water temperature is 103°F. The water temperature is 115°F. “We’re all good,” says the boiler if it could talk. No. I’m cold.

Another Outdoor Temperature Sensor Problem

When the sun stopped hitting the outdoor air sensor a couple of hours later, things were quite fine again. However, I noticed the outdoor temperature reading was still a stubborn eight degrees above actual temperature according to the two apps and Alexa. I tapped my photographic memory and confirmed what I thought I saw earlier in the sunny afternoon. The sensor was not only installed on the south-facing wall; it hung barely an inch above the PVC exhaust tube. The boiler exhaust was heating the temperature sensor to read about ten degrees higher than actual, even in the shade and at night.

Commissioning Report and Recompense

I had filed my report with all diagnostics and things that needed fixing. Let’s call it commissioning, and I sent that to the contractor. The one thing I could not figure out was why the thermostat would not shut off the boiler.

They moved the temperature sensor to the north side of the house to fix that part. The thermostat needed another wire. The old boiler worked with only the red and white connections, but it needed a 24V common connection to control this boiler.

They moved the temperature sensor to the north side of the house to fix that part. The thermostat needed another wire. The old boiler worked with only the red and white connections, but it needed a 24V common connection to control this boiler.

Finally, it all worked, but I needed to decrease the reset schedule again to achieve better efficiency.

The Grand Finale

You’ve all seen movies like Die Hard or Terminator, where the bad guy or cyborg has taken enough beatings to be killed a dozen times over, and then surprise! The music shrieks. It’s not dead! Aaaaaahhhh! Yep. That happened to me on this project.

As I finished reprogramming the boiler reset configuration again, I examined the brazed plate heat exchanger configuration. Dude, that thing is connected backward! An attentive engineer would have noticed that from the system cartoon last week. You think I makee mistakee last week? NO!

As I finished reprogramming the boiler reset configuration again, I examined the brazed plate heat exchanger configuration. Dude, that thing is connected backward! An attentive engineer would have noticed that from the system cartoon last week. You think I makee mistakee last week? NO!

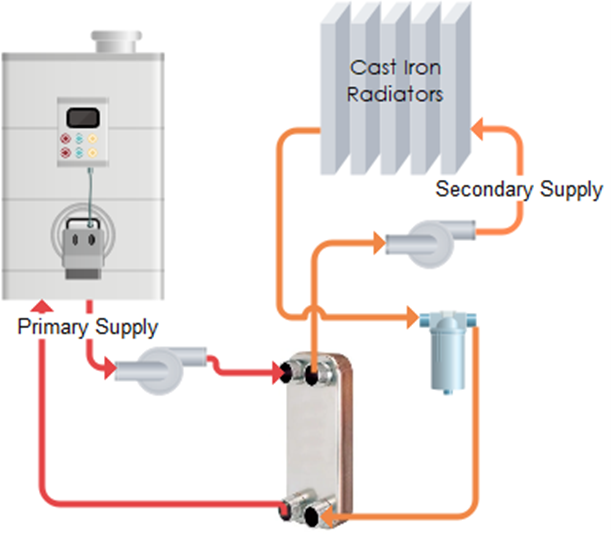

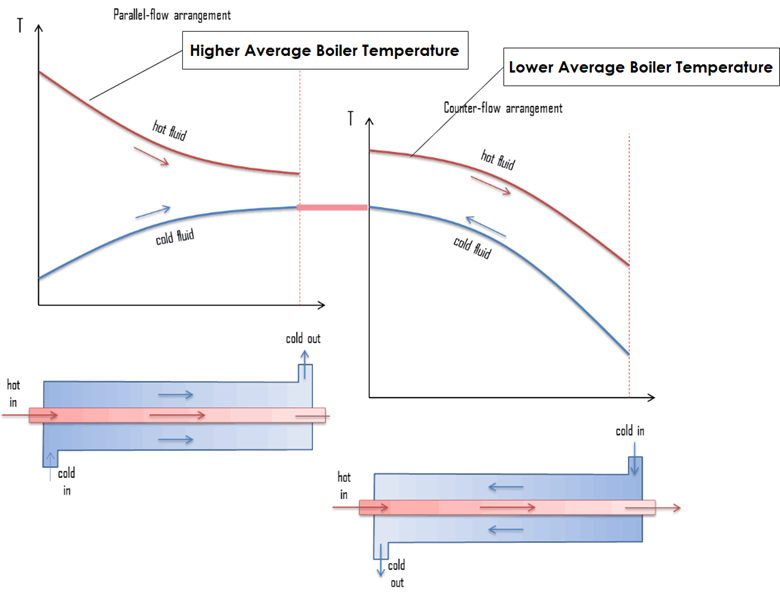

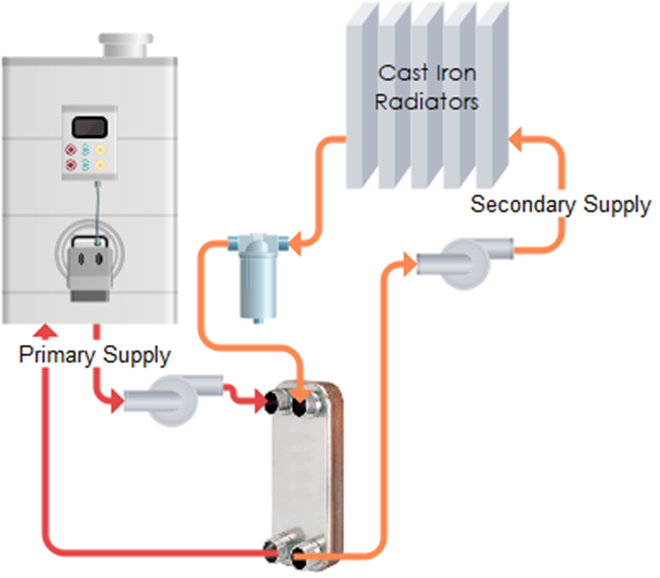

Brazed plate or plate-and-frame heat exchangers should be configured in counterflow, not parallel flow. You can see in the first cartoon below, parallel flow, that the supply water temperature to my radiators can be no hotter than the return temperature to the boiler. That’s wrong. We want the supply temperature to the radiators to be as close to the supply temperature from the boiler as possible. To do that, plumb it in counterflow per the second cartoon below.

Original Configuration

Correct Configuration

Correct Configuration

What’s the diff? See the chart below showing heat exchanger temperature profiles for parallel (original configuration) and counterflow (correct configuration). The pink line between the two charts shows the supply temperature to the radiators – the “cold” side. To have equal capacity from the radiators, the boiler in the parallel configuration needs to operate at substantially higher temperatures and substantially poorer efficiency.

What’s the diff? See the chart below showing heat exchanger temperature profiles for parallel (original configuration) and counterflow (correct configuration). The pink line between the two charts shows the supply temperature to the radiators – the “cold” side. To have equal capacity from the radiators, the boiler in the parallel configuration needs to operate at substantially higher temperatures and substantially poorer efficiency.

Next week I will wrap up this course with commentary about blown savings and false beliefs in code compliance.

Next week I will wrap up this course with commentary about blown savings and false beliefs in code compliance.

[1] Annualized fuel utilization efficiency = the net efficiency over all conditions throughout the heating season.

Outdoor Temperature Sensor Problem

Outdoor Temperature Sensor Problem Correct Configuration

Correct Configuration