Last week, we explored the state of EM&V 2.0 and its considerable, to say the least, constraints. This week, we look more intensely at fallacious “automated M&V”.

Automated M&V is an oversold and over-hyped concept. When something is automated, it takes inputs (data) from various sources, often hundreds of sources, with high frequency, maybe by the second or on a Hertz (many times per second) scale. Then the brains of the automated doohickey compute and translate the data into solutions or outcomes. For buildings of all types, from single family homes to large commercial and industrial facilities, automated systems are limited to HVAC and process control systems.

The State of Disaggregation

Automated M&V requires disaggregation of meter data to decipher electric loads. This includes analyzing load shapes to determine what the major loads are, and how frequently and how long these loads operate. For an example with realistic data, refer to Learning Calculus via Demand and Energy. That only provides the what and how often. Another monumental challenge would include determining the impact on the load (kW) and duration of a widget replacement.

It may be fairly easy to disaggregate the big loads like electric water heaters, clothes dryers, air conditioners, refrigerators and furnaces (fans). How? First, they are substantial loads and will rise above the noise of baseline usage. Second, they have, to use an overhyped sexy term, digital signatures. For example:

- A water heater will fire at regular intervals when not in use and will operate for a block of time when in use.

- A clothes dryer will have no regular intervals, but it will operate in blocks of time.

- An air conditioner’s operation will vary with the weather, as will a furnace fan.

- A refrigerator is like the water heater but different frequency and magnitude.

It is entirely possible to disaggregate these loads and determine their energy consumption with utility interval data. However, there may be monkey wrenches like a stand-alone freezer that may be hard to discern from a refrigerator or maybe two refrigerators and a freezer.

Moving from larger to smaller equipment quickly starts to complicate things, exponentially. Small loads like lighting under 100 Watts are down in the weeds of a typical residential load shape. However, this is still not a technology problem. There are a couple options for capturing data for lights and other small loads.

What’s Your Frequency, Kenny?

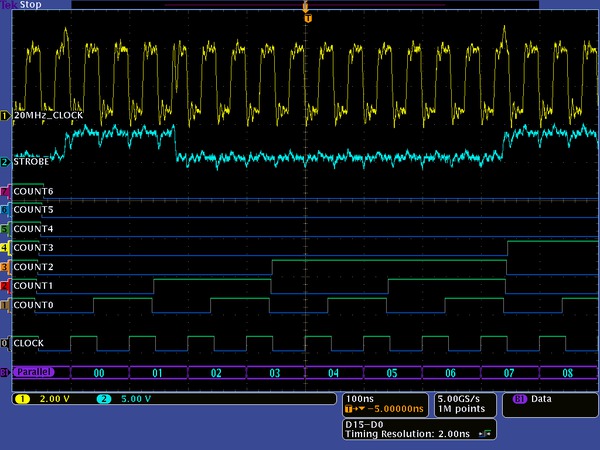

Electric loads have electrical signatures; think oscilloscope. Below is a random example I pulled off the internet. Residential loads could be disaggregated using high-frequency data as shown. The problem is that the most granular smart meters provide demand readings once per minute as described in a paper entitled “Load Disaggregation Technologies: Real World and Laboratory Performance”, presented at this year’s ACEEE Summer Study on Energy Efficiency in Buildings. Many provide data only once per fifteen minutes or once per hour. One minute is an eternity for detecting loads as small as light bulbs or even refrigerators.

This paper from the University of Massachusetts – Amherst clearly supports my thesis. According to the U-Mass paper, the most granular smart meter of the day takes data once per minute, confirming what I see in the ACEEE paper.

As the U-Mass paper shows, data need to be recorded at least every second to disambiguate[1] electric use. Even with that granularity, someone on the other end must break it down. In other words, it is still far from “automated M&V.”

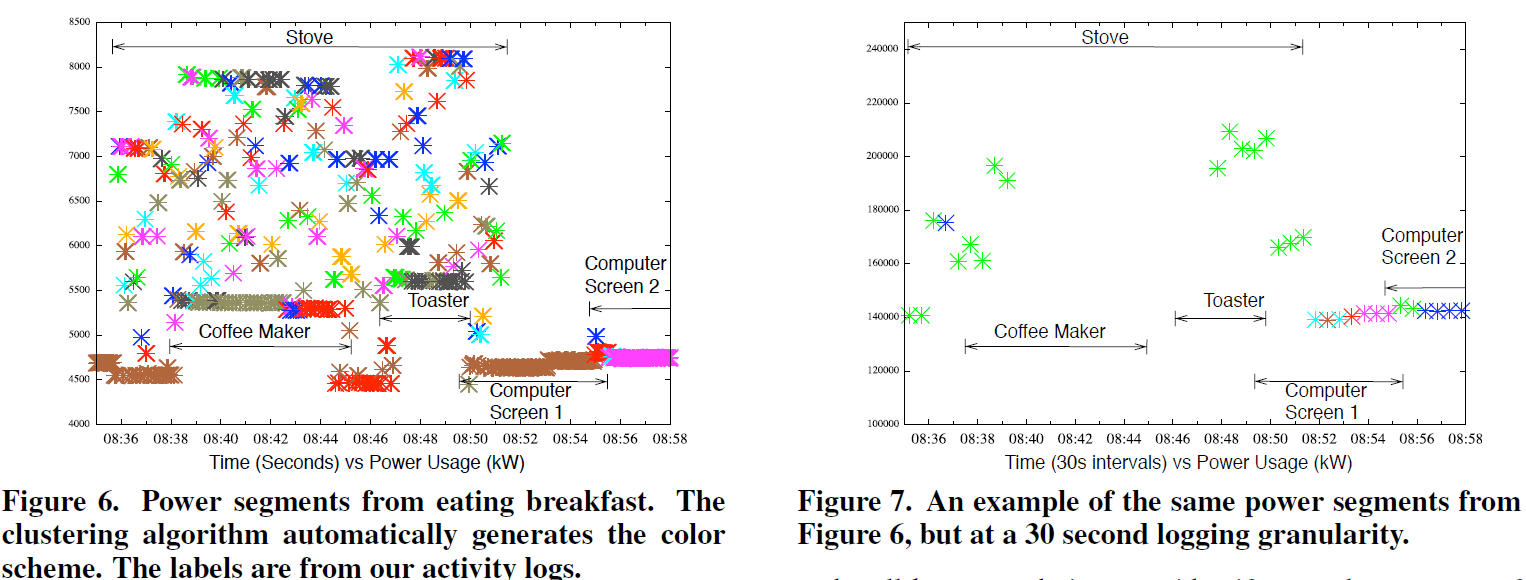

The U-Mass effort used TED, “The Energy Detective”, to capture home meter data every second. You can see in the paper’s plots to the left the difference between every second (left) and every 30 seconds (right). Interpretation: reads every thirty seconds are worthless for small loads like appliances and light bulbs.

Remote M&V, as opposed to the bogus “automated M&V”, is entirely within inexpensive technological capabilities available today. However, per my research, smart meters aren’t nearly good enough. Therefore, other devices, like TED, at minimum are needed.

Large C&I Auto M&V?

At a recent conference, I witnessed a guy preaching[2] the virtues of data monitoring equipment embedded with control systems for large C&I equipment and systems. That’s just grand, I thought. Yes, it is entirely doable, but design firms and contractors with no interest in what we need are between their customer and us. Who is going to pay for it even if it is relatively cheap, and who is going to make sure it all works, and how will M&V pros get access to the data? As I mentioned a couple weeks ago in new construction program failures, people clearly do not want anyone looking in their underwear drawer. And it costs more money, takes more time, and causes more headaches. What’s not to like?

Secure Data

Remember the Target hack a couple Christmases ago? That hack hit Target hard, and it hasn’t fully recovered to this day. Do you know how the hackers tunneled into Target’s corporate system to get at its customers’ credit cards? Through a controls contractor’s unsecured access to the company’s building automation system. There are ways around this, but automatic is the last word that comes to mind.

Conclusion

When machines alone can diagnose and remedy maladies, auto M&V may exist as well.

[1] Thank you, paper. My vocabulary just grew by one word.

[2] Really – I thought Jimmy Swaggart emerged from retirement to try his hand in the efficiency space.