Last week we introduced exergy and at least one application of it in a building. First, let me make something very clear, for the refrigeration cycle, if I’m cooling beer or freezing leftovers, the heat that is sucked out of those masses is rejected somewhere else. For refrigerators and freezers, it is rejected to the room in which they exist. For air conditioning, most commercial refrigeration, and all industrial refrigeration, it is rejected outside – unless, it is captured for useful heating.

Commercial HVAC

For commercial HVAC, if CONsultants don’t think holistically about the entire heating and cooling needs, and they rarely do, look out! I wrote an entire post on one example of myopia concerning efficiency with data center cooling a few months back, for example. Today we have more examples.

Hey, Kool-Aid!

A few weeks back I attended an industry meeting, which I can thank for this line of exergy posts. A presenter featured some really good ideas and some short-sighted ones. This Kool Aid’s flavor was that heat recovery is always good. No. It isn’t.

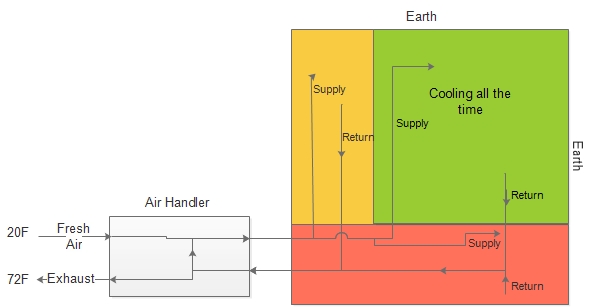

See the cartoon to the left, which shows a simplified version of a middle floor with three temperature control zones. For simplicity, consider the top to be north. We have an interior zone that needs cooling all the time because it has almost no heat loss and only heat gains from lights, people, and anything that uses electricity. The south and west walls are exposed to cold or hot northern-plains weather.

Assume today it is 20 degrees outside, as shown. In the morning, the south and west zones need heat. The core zone needs cooling as usual. The simple way to cool is using a little extra outdoor air, mixed with return air.

Bad Code Design

The following design complies perfectly with energy code but wastes gobs of energy, and I mean gobs by the trainload of coal. An engineer should be fired for providing heating to these south and west perimeter zones through duct coils. This is perfectly code-compliant but wastes energy like nobody’s business. This is why code compliance is a fallacious dreamland that means nothing. What are the problems with this terrible code compliant building?

- The same air used for cooling the core zone is used for heating the perimeter zones, producing vast amounts of simultaneous heating and cooling.[1]

- Heating air is delivered at the ceiling. There is a reason hot air balloons leave the earth. Hot air rises, it doesn’t fall. In an attempt to force warm air to the people space, a small jet engine’s fan power is required. This still doesn’t work well.

This type of design is about as common as the Honda Accord. Call me for a better idea.

Even Dumber Code Design

To add more pain and misery to this design, some designers think, gee, wouldn’t heat recovery be great? We are exhausting 72F air and bringing in 20F air. Wouldn’t it be great to capture heat from that exhaust stream to preheat the outside air to 55F or even 65F?

No.

Return air mixes with outside air. When you mix a lot of 72F air with a little bit of 20F air, you get air that is a little cooler than 72F. Think of tossing an ice cube in a pot of boiling water. Doesn’t cool it down much does it?

Result: a heat recovery unit is a 100% waste of money because it is never needed. It also adds pressure drop and more fan power to move the air through the unit. Great! What’s not to like?

Does this happen? Oh yeah! I reviewed one such grand design for a shiny new University of Wisconsin building, not long ago.

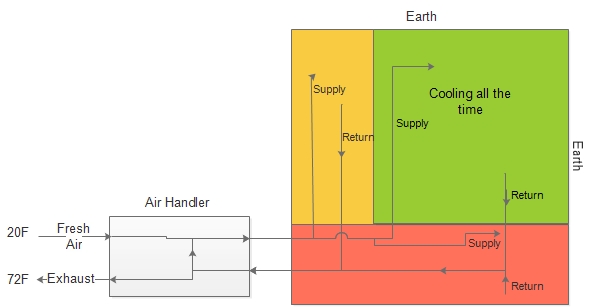

A Case of Misbegotten Exergy Extraction

Here is where the Kool-Aid is chugalugged. Go back to last week’s post under the “Buildings” heading near the bottom. Click it! Click it! Go!

The following is another great (not) idea. Rather than “waste” energy to heat the perimeter zones, use a heat recovery chiller to pull heat out of the 72F exhaust and boost the temperature up to 120F water for heating the perimeter. Essentially, this cools the exhaust air to be closer to outdoor conditions. This is what exergy is all about.

A retrofit was used to achieve this in the building caricatured above. The chillers act as water to water heat pumps sucking heat out of the 72F exhaust and boosting it to 120F water for space heating.

Great! Not so much.

To do this, I need to buy chillers, of course, but I also need to hack into the exhaust duct with a water coil and pipe it up. That may also require some re-engineering of the air side because now I’ve added pressure drop.

You have to think big picture folks! Push here, and something will come out there!

What a fantastic project! The facility no longer needs to purchase expensive district steam. Electricity use increases a little because of fan power and energy required for the chiller.

I have a better idea. Why not use small 95% efficient natural gas boilers? I guarantee it would be a lot cheaper and easier. No dinking around with the air side is required.

Energy cost differential would be different. The options are a little extra electricity or a little extra natural gas, in exchange for expensive district steam.

For the next wave of efficiency, we must overthrow the one-track mind. Think, man!

[1] Yes, variable air volume, blah, blah, but this doesn’t work. See 2.