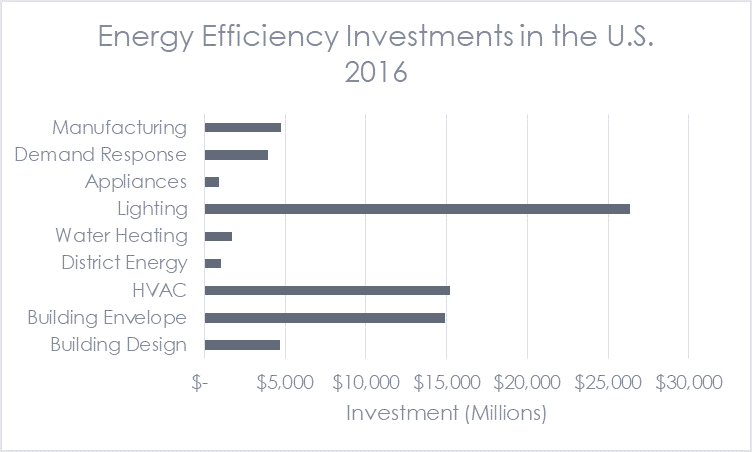

This year ACEEE published a three-part series on why people and companies invest in energy efficiency. First, they provide some guesstimates of energy efficiency investment in the United States. Their researched estimates vary from $60 billion to about $120 billion, annually. Is this a reasonable guesstimate? According to their State Scorecard, program spending on natural gas and electric demand-side management programs held steady at about $7.5 billion in 2016. Check. The International Energy Agency pegs worldwide investment at $231 billion and about $40 billion in the U.S. Check. As a laugh test, $100 billion is a measly 0.5% of the U.S. economy. Check.

One of ACEEE’s sources is the Advanced Energy Economy 2017 Market Report. That report pegs efficiency spending in buildings and manufacturing at about $75 billion, broken down as follows.

Finding #1: Manufacturing Does Diddly

There are always exceptions, and some companies are superb, but in general, manufacturing and industrial energy users do not care about efficiency. Industrial opt-outs are a sham because either:

- The programs available provide poor value to these customers;

- The programs’ spending caps are too low; or

- These customers do not want to pay the efficiency rider, or do efficiency.

On top of these, just like commercial efficiency, manufacturing, and industrial facilities probably have 30% savings potential in:

- Low/no cost measures (retro-commissioning),

- Cost effective retrofits (two year or faster simple paybacks), and

- Process improvements, especially when embedded in strategic energy management planning.

For additional data points on manufacturing’s interest in efficiency, I recently spent 90 minutes talking with the president of a 600 head engineering firm with a major line of business serving new construction for manufacturers. Without my asking, he said plainly; manufacturers do not care about energy efficiency. He said if a design aspect saves energy with no additional cost or the slightest risk of impacting production, they might do it. On that note, there are plenty of no-cost things manufacturers can do during construction to save energy. Designers and builders need incentives to do so, however. I recently wrote about this need to skewer the sacred cow of incremental cost in Buggy Whip Bites the Dust.

People, momentum, stubborn ways, and risk aversion are all barriers to efficiency – many times, much more so than cost.

Finding #2: Policies and War Matter

ACEEE’s first blog post in this series, as you might expect, says energy efficiency policies make a big difference. I would add that survival also matters. I took an interesting course in college called history of technology. What I learned: survival is the mother of all inventiveness.

Just as I learned that thermodynamics is all about efficiency, or output divided by input, technology is driven by winning wars – communications, satellites, nuclear power and dozens of spinoff technologies, everything in your cell phone, you name it. Guess what, the big driver of the biggest advance in lighting technology occurred as a result of the need to save energy with lighting for war-time manufacturing in the 1940s.

Taking it from there, state efficiency policies helped push fluorescent technology into homes, and of course most recently, policy rushed the introduction of LED lighting into homes.

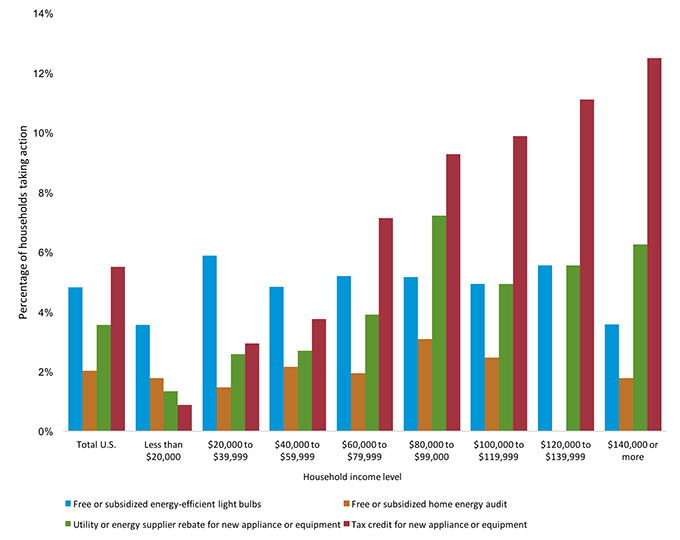

Finding #3: Utilities Lose to the Government

Say it ain’t so! In ACEEE’s second of three blog posts, every income bracket of households claimed more participation in tax credits than utility programs.

On the one hand, this is a little misleading because many consumers take free or subsidized audits and light bulbs sponsored by utility programs. On the other, considering most households do not itemize their tax returns, the tax credit counts are huge compared to the number of consumers taking free or subsidized products and services.

Finding #4: Something Else Made Me Do It

In ACEEE’s second post, German manufacturers indicate just over half implemented efficiency to save energy. The rest did it as a secondary benefit. In other words, the primary driver of the latter group was non-energy benefits. For small businesses, the non-energy benefits were even a bigger driver by about 2:1 over saving energy. Indeed this is true everywhere; not just Germany.

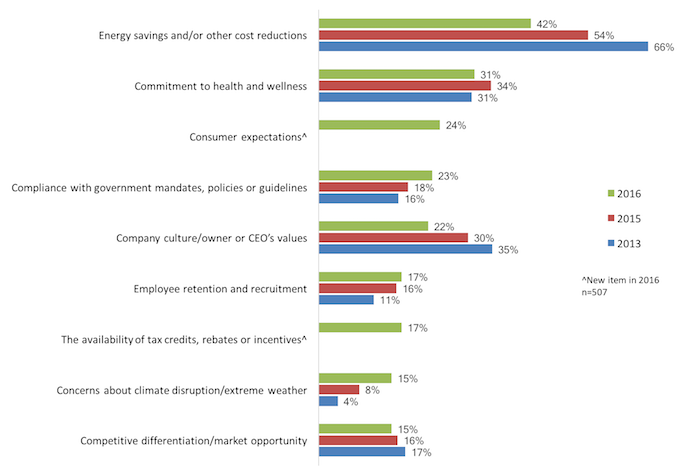

Finding #5: Companies Care Less About Efficiency

Again, from the second post, excerpted chart below, companies are trending toward caring less about efficiency. Cost reduction benefits are plummeting as a reason for implementing efficiency, as are culture and values, and market differentiation. Fear seems to be on the upswing with climate and government mandates as growing reasons. Under Trump, the fear of government mandates is likely to fall if CEOs are paying attention, and they are. I think with millennials making up a plurality of the workforce, the fear of climate and weather disruption is not going to subside anytime soon.

Parting Shots

Speaking of necessity (Finding #2), lighting has been the golden goose for thirty years. Now that the goose gravy train is near the end of its run, it is not the time to curtail.

Taxpayer subsidies for renewable energy need to go away. These are major handouts that shift the cost of electric bills from energy users to taxpayers, substantially masking the true cost of electricity. It is also reverse welfare.

Climate advocates talk about shifting the true cost of energy[1] all the time. What about this shift? There is a rising concern for climate shown above. The subsidized flood of renewables is making the cheapest, cleanest source of climate risk reduction[2] substantially less cost-effective than it is. Can we take the fingers off the tax-code scale, please?

[1] Societal cost of emissions

[2] Efficiency and demand response