This week, we continue the discussion of ASHRAE Standard 211, Standard for Commercial Building Energy Audits. For ease of consuming this post, I suggest destroying 1/900,000th of a conifer by printing last week’s post, which includes a super summary of the approach, process, and contents of the three levels of energy audits in one table.

The Nerd’s Arms Race

One thing is certain regarding human nature: people love to complicate the hell out of things. Consider the tax code, code of federal regulations, and any part or level of government. The private sector follows similarly, maybe with different reasons.

For instance, ASHRAE publishes a series of “handbooks,” which are actually full textbooks. There are about five published sequentially, one per year. The old handbooks from the 1970s had good stuff like an approximated U-value of a below-grade concrete wall, like that of a basement. In the newer editions, probably to protect themselves(?), we have ginormous equations filled with variables that require many more levels of research. Thanks for the improvement.

Complication proclivity syndrome may be boiled down to three drivers:

- Social – policy attempting to steer people in a desired direction or attempting to make things “fair.” The results are typically the opposite of the desired outcome.

- Legal – if we provide valuable information, a scorned geek who misuses it may come back at us with a lawsuit.

- Technical – engineers and other technical in-duh-viduals love complication. Like 1 above, the outcome is usually the opposite of the desired objective. For instance, I wrote about the insanely complex variable air volume system, still promoted by ASHRAE, many times, including here, here, and here. Check them out.

I will return to the arm’s race below.

The Purpose of Audits

It is very wise to define a purpose before building an apparatus to accomplish that purpose. I do not see this in Standard 211. I see the purpose of the standard, but what is the purpose of the three levels of audits? This is an excellent question.

Level 1 Audit Purpose

The Level 1 audit must provide benchmarking of the facility. I.e., how does the facility in question stack up against peers in similar climates? It must also provide a basic description of the types of HVAC and lighting systems in the facility. Finally, it must provide broad opportunities for energy efficiency measures. As noted last week, measures should be categorized by (1) do it now, (2) upgrade on equipment failure, or (3) dig deeper.

The purpose of Level 1 is to assess the total opportunity, identify specific measures, and provide next steps for each measure.

Level 2 Audit Purpose

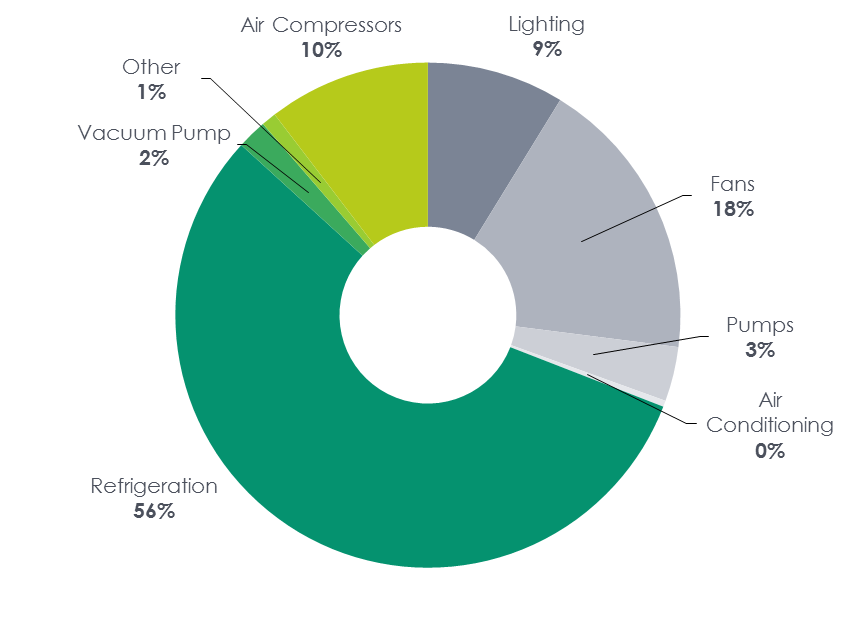

The Level 2 audit provides an end-use of energy breakdown. An example is shown below.

Level 2 Audit – End-Use Energy Breakdown

While Standard 211 is not meant to cover industrial facilities, that doesn’t’ fly when serving utility programs and industrial customers. We apply the audit level standards and concepts to any customer type.

The Level 2 audit includes cost and savings guesstimates for each measure. Analyses include what we call a custom-prescriptive approach along with the engineer’s mental library of past projects and resultant intuition. Information for the analyses may include rules of thumb[1], actual operating characteristics, and implementation cost estimates based on past projects, reference manuals, and an X-factor. The X-factor is complexity multiplier based on the engineer’s experience and intuition.

The purpose of Level 2 is to provide ballpark cost and savings estimates. Ballpark means one significant digit, which is one digit, only, that is not zero. Precision may be ±30% for each measure, but when rolled together, precision increases substantially. For most measures, this provides all the information needed for customers to say yes. For some measures, the response is, I’m intrigued with that. Let’s take it further.

Level 3 Audit Purpose

The Level 3 audit delivers investment grade precision for each measure. The analysis includes specifically detailed inputs to prove results on the back end. Actual equipment efficiencies and measured or metered parameters are used in the analysis. Costs are developed with material, labor, design, project management, and any back-end testing. This includes hourly rates, demolition and disposal cost, and countless unique considerations for the particular application and facility.

The purpose of Level 3 is to provide investment grade analyses that can be metered on the back end to within 10% of the estimate. Level 3 is warranted for a combination of high measure cost and uncertainty.

Nerd’s Arms Race Purpose

There is no purpose of the nerd’s arms race. In engineering, the nerd’s arms race may be described in one word: entropy[2]. Specifically, it adds reams of superfluous activity and information about irrelevant, extraneous factors that no one needs. Examples:

- Level 2 requirements have grown to what used to be Level 3 requirements. Level 2 cost estimates now require labor, material, design fees, permits, taxes, and more. Good grief. Out of bounds and out of scope.

- Level 2 requirements include inventories of equipment. This too is out of scope for the purpose of a Level 2. Consider that lighting was recently replaced with LED and the light levels are good. Done. Whoops, I need to count the lights. I might as well count dust bunnies.

[1] E.g., how many full load hours or what percent speed reduction or percent power versus temperature can be achieved?

[2] The simple definition of entropy is loss, waste, chaos, and disorder. Example: that’s an hour of my life I’ll never get back. It’s scrap and rejected product from a manufacturing process.