In January, I wrote about code compliance and that while energy codes keep ratcheting down energy intensity in theory, reality is misery. That post was a thinly veiled advertisement for my AESP National Conference session in the Lion’s Lair, and that presentation can be seen here. My Lion’s Lair proposal was a thinly veiled pitch to fix what would be the equivalent of curing cancer for commercial HVAC systems.

The cancer is the widely used variable, air volume system. Another boondoggled application of one such system triggered this post. The boondoggle was part of an evaluation we are doing on the East Coast.

But first, allow me to describe how the cancer is supposed to work. If you have never experienced a building that is too warm in one room and/or too cool in another, you can quit reading now.

Ok. Now that I’ve lost no one, you know what temperature control zones are. They are spaces that have, or should have, some type of dedicated way to manage temperature. Possibly the easiest way to think of this is a bedroom with a window air conditioner. That unit will keep the room right where you want it, temperature wise.

If you have never experienced a room packed with people getting “stuffy” and warm, you can quit reading now.

Ok. Now that I’ve again lost no one, some spaces may need cooling at any time during the year. In fact, some spaces need cooling all year. Consider a data center or a data center closet. Data centers produce so much heat, they need cooling just about all the time.

If you have never sat in an outboard zone, that is, one next to an exterior wall, and especially large windows, where it is cold in winter, you can stop reading now (You people in Arizona, stay put, please).

Ok. Since, yet again, you’re all still here, some places need substantial heating while other spaces need substantial cooling, at the same time.

Meanwhile, all people in occupied spaces need fresh air for health and comfort reasons.

Variable air volume systems were concocted over decades to provide all these things, efficiently. The problem is, to minimize energy consumption per theory, it’s impossible to attain or even come close. Essentially no one understands how these systems work. They have varying fan speeds, varying outdoor air percentages, varying air flows in 10, 20 or 30 zones. They have heating coils in the central fan unit and maybe heating coils in zones. Don’t forget, everyone needs their share of ventilation. Sequencing and orchestrating all this crap for efficiency is next to impossible.

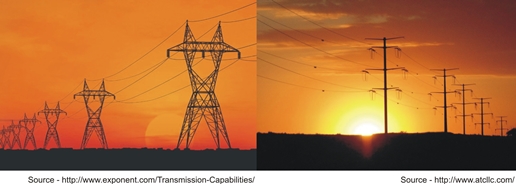

I’ll make a clear demonstration that anyone can understand. See how electrical transmission lines have evolved over the decades. The example on the left is something out of the 1960s built like an Eiffel Tower. Why? I don’t know. Engineers liked building monuments for themselves? Pretty. Utilities said, “No more monuments. We’re going to build simple, inexpensive monoliths.” Put the tinker toys away. Heating and cooling systems are exactly the same, except the Eiffel monument clusterflunks are still in production.

This brings me to the East Coast case we recently evaluated. This included energy recovery and demand controlled ventilation. In case you don’t know what these are, I’ll explain them. An energy recovery unit simply swaps heat from exhaust air to incoming air, and vice versa in the summer. Seventy degree air is exhausted from the building, and while that happens, it gives up its heat to incoming air, to warm it from maybe 20 degrees to 55 degrees. (Go ahead Arizona, yuk it up) Demand controlled ventilation simply measures CO2 in a space, and it is used to control ventilation rates. More people create more CO2. When the CO2 concentration gets high, outside air is brought in to dilute it – more fresh air for occupants.

Remember the data center and packed conference rooms that need cooling all year? That is provided by cold fresh air when those outdoor conditions exist[1], which in the upper Midwest and Northeast is about 300 days per year[2]. There is always some space that needs some of this. Due to the nature of spaces served (trust me), standard control requirements negate the need for CO2 control or the need for energy recovery. In other words, these two features are a waste of money. Indeed, per our calculations for the East Coast project, only 12% of the predicted savings are being realized, per metered performance and not a guess.

Nobody understands these systems.

That is, except for very few engineers, like guys who like to tinker with 1960s muscle cars – cars that never work quite right and always need tuning.

Where does the cure for cancer come in? I said to the Lions, who were vigorously nodding their heads in agreement, that killing variable air volume systems would be equal to a cure for cancer. It’s not the only premature cause of death, but a major one. This wouldn’t be the end-all of code compliance problems, but a major step in the right direction.

“But Jeff, you guys have a variable air volume system in your office. You’re a hypocrite.” Glad you mentioned it. Our own system drove me over the edge toward the message in this post. We’ve had many problems that would never be fixed in a normal application. The fan wheel resonated like a freight train. The fresh air dampers would shut because the controls thought the water coil might freeze. The air noise in the big conference room drowned out presenters. People in the lobby were freezing. Since we are energy nerds, we tinker, tweak, fall down, get up, babysit, and keep at it. Normal people don’t like screwing around with problems.

[1] Also known as free cooling, or economizer

[2] Or a lot anyway.

Fresh air is very important for cancer cure. This is very good article you should write more on this topic.