The last few posts[1][2] featured an overview and complete report card on load management to get beyond net zero to real zero, a term I discovered last week.

As promised, I will describe some permanent peak load reduction opportunities this week. Like many efficiency solutions, blocking and tackling approaches are the most effective.

Peak Load Reduction – New Construction

I’m going to stick with some big hitters. A person could write forever on this topic.

Home Envelope

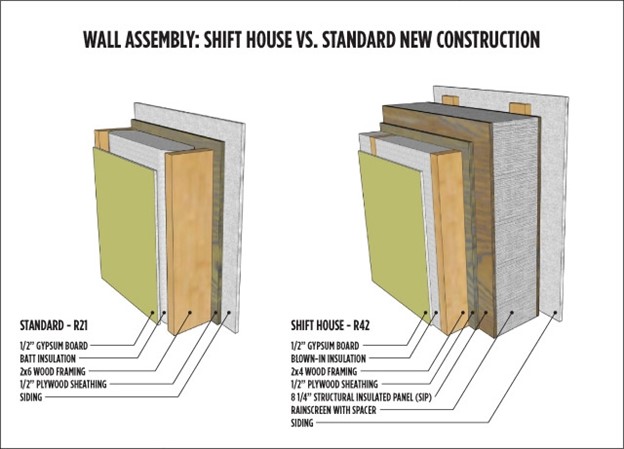

Single-family homes must be super-insulated to minimize heating loads in cool/cold climates. The cartoon below provides a nice example of super-insulated versus code minimum. There are many construction options you can research yourself—key words: passive home wall design.

Windows are a big challenge for the overall U-value of a facility, which is its heat transmission in Btu/hr-F. I.e., Btu per hour (like the rated capacity of a furnace or heat pump) times the temperature difference between indoors and outdoors.

Windows are a big challenge for the overall U-value of a facility, which is its heat transmission in Btu/hr-F. I.e., Btu per hour (like the rated capacity of a furnace or heat pump) times the temperature difference between indoors and outdoors.

Assume a home façade with 90% wall area and 10% windows. Also, assume a typical window U-value of 0.33. The relatively low U-value of the windows is a major anchor. Switching from standard to “Shift House” construction shown above while not improving the windows only decreases load by 28%, even though the wall is 90% of the façade.

Highly insulated windows are costly. I would consider two windows per opening and forget the operability. Use an air handler with ventilation capability. A tight, heavily insulated home won’t have much cooling load; therefore, operable windows are less important from an energy perspective.

Commercial Buildings

Commercial buildings include offices, k-12, universities, healthcare, and government. Insulate the heck out of the roof. Wall insulation is less important, and the thermal mass of the walls is more important for commercial buildings. Simulators show that adding insulation to walls may increase cooling energy consumption. I’ll skip the why because it’s minor and can be overcome with outdoor air flushes overnight.

Displacement ventilation is a must. For a cartoon of how displacement ventilation works, click here. To get smart on the topic, read this ACEEE paper.

Residential, Commercial, Industrial

We can’t afford to dump heat and simultaneously pay to heat something. Water heating is a low-temperature heat requirement. Depending on the climate, all homes and commercial buildings should get most or all of their water heating needs from heat rejected from space cooling. The southern tier of states should have almost no water-heating energy requirement for residential and most commercial buildings.

Commercial buildings in cool/cold climates have simultaneous heating and cooling loads in different parts of the building. Move the heat from spaces that need cooling, typically the interior of the building or spaces with high internal loads (lots of people or equipment), to spaces that need heat.

Probably every food-processing plant is simultaneously rejecting heat from an HVAC or process cooling load to the atmosphere and adding heat with natural gas for hot water – we can’t do that in a decarbonized and mostly electrified manufacturing facility.

See Best Programs with Market Transformation for opportunities to capture waste heat.

Heating and Cooling Sources

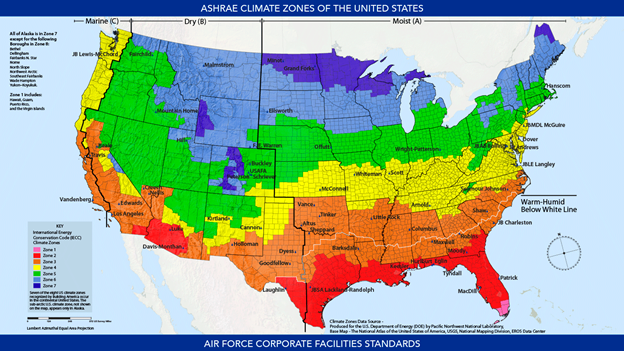

For zones 5-7 in the ASHRAE / Air Force map below, I recommend ground source heat pumps or a highbred air source heat pump to avoid massive peak heating loads with electric resistance. Cold climate air source heat pumps are fine now and competitive from a cost-of-operation perspective, but as full heating electrification comes into view, we can’t have a few days a year when loads are all met with toaster coils. That will crash the grid.

Peak Load Reduction – Retrofits

Peak Load Reduction – Retrofits

Residential

Shifting into high gear to knock out more approaches, here are some items already discussed above.

- Hybrid air source or ground source heat pumps in the north

- Heat pump water heaters and no electric resistive water heaters

- Attic insulation now, wall insulation when the opportunity arises (e.g., replacing siding)

Commercial

- Heat recovery chillers for buildings with four-pipe systems (supply and return chilled water and supply and return hot water)

- Heat recovery from commercial refrigeration in grocery stores

- Evaporative condensers for grocery store refrigeration and floating head pressure for energy savings

- Displacement ventilation (see new construction above)

- Domestic water heating using heat recovery chillers

Industrial

In addition, to waste heat recovery for process heating, industrial facilities typically offer a bounty of oversized equipment, often running wild with no speed or even reliable on/off control to avoid equipment damage and misuse of expensive utilities like compressed air. For example, replacing something powered by compressed air with electricity is a permanent demand reduction. Every opportunity is unique and must be evaluated on an 8,760-hour-per-year basis for demand reduction estimates.

Thermal Batteries

In the next decade or two, I project the most impactful permanent demand reductions will come from thermal energy storage with phase change materials. Phase change materials (PCMs) have a great capacity to store heat or lack thereof (e.g., refrigeration, space cooling, freezers) in compact containers. Materials include water, fats, hydrocarbons (waxes, etc.), and many types of saltwater solutions.

Energy storage with PCMs enables heating or cooling loads to be shifted out of peak periods to off-peak, as permanently as permanent gets in the equipment world – i.e., daily for 20 years in many cases. If the device heats, cools, or freezes and is connected to the grid, it can deploy energy storage like a battery for a small fraction of the cost.

[1] https://michaelsenergy.com/demand-response-primer/

[2] https://michaelsenergy.com/a-ten-dimensional-demand-response-examination/

Peak Load Reduction – Retrofits

Peak Load Reduction – Retrofits