Last week a Yahoo News reporter headlined an article, Biden Administration Seeks to Lower Industrial Greenhouse Gas Emissions-and-That-Won’t Be Easy. My first reaction: It won’t be easy to decarbonize any sector: residential, commercial, industrial, and transportation, although I did see that, like wind energy, the passenger blimp is making a comeback (say whaaat?). Will it replace passenger jets? I don’t think so.

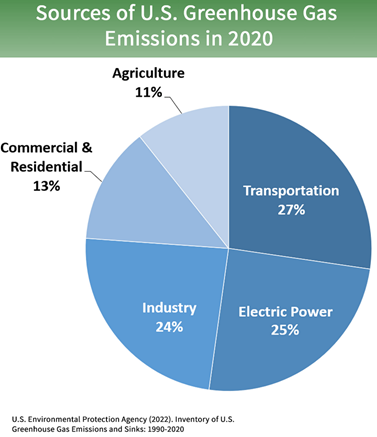

I focus on the above-linked article and industrial electrification and decarbonization in this post. The Yahoo author references the chart below for shares of GHG emissions. I assume that emissions from electricity generation are not double counted into the industry’s share of electricity consumption.

The author writes, “Cutting fossil fuels out of industry is a more complicated task than switching to electric cars or replacing coal-fired power plants with wind farms, as it requires changing the way everything from plastics to cement are made.”

The author writes, “Cutting fossil fuels out of industry is a more complicated task than switching to electric cars or replacing coal-fired power plants with wind farms, as it requires changing the way everything from plastics to cement are made.”

Cutting fossil fuels out of industry is just as easy as it is for these other things. Just declare it so like the Senate just declared EV batteries shall be recycled. Someone posted that on LinkedIn, and my comment was, “they just pass laws, and it shall be so. I think they should pass a law to cure pancreatic cancer by 2030, and that too shall be so. We’re just not trying hard enough.”

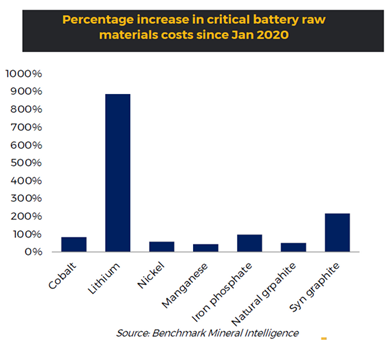

Making EVs and building wind farms is easy, but they come with great challenges that few care to point out, but I will. Do you think gasoline and grocery bills have increased significantly in the last year? Lithium prices edged up by 900%, and EV sales are only 4% of total light vehicle sales – i.e., demand is minuscule. What does it look like at even 10% of market share?

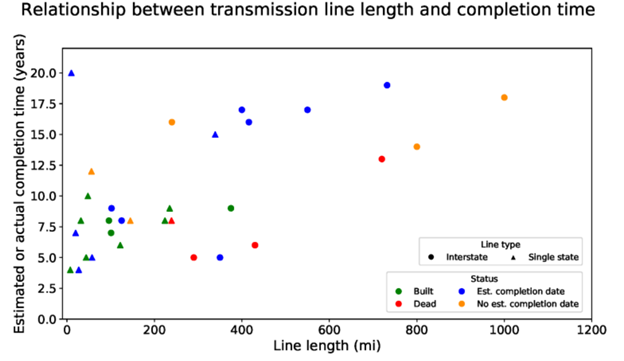

Building wind farms is also easy but accommodating their generation into a reliable, inexpensive grid is not easy. The Kennedy School at Harvard says experts claim we need over a million miles of new transmission lines to decarbonize. Transmission lines for decarbonization (long ones) take over 15 years to build. The Harvard paper says the environmental impact study (government red tape) takes eight years. On the private side, people hate transmission systems. They don’t want to pay for them. They are “unnecessary.” They don’t want to look at them, and they don’t want to be a bug crushed by the boot of public-private partnerships.

Building wind farms is also easy but accommodating their generation into a reliable, inexpensive grid is not easy. The Kennedy School at Harvard says experts claim we need over a million miles of new transmission lines to decarbonize. Transmission lines for decarbonization (long ones) take over 15 years to build. The Harvard paper says the environmental impact study (government red tape) takes eight years. On the private side, people hate transmission systems. They don’t want to pay for them. They are “unnecessary.” They don’t want to look at them, and they don’t want to be a bug crushed by the boot of public-private partnerships.

I’m all for decarbonization if it makes us more competitive against adversaries like the Chinese Communist Party, Russia, and Belarus. The CCP is building and commissioning coal-fired power plants at a breakneck pace because it is the cheapest and most reliable source when emissions don’t matter.

I’m all for decarbonization if it makes us more competitive against adversaries like the Chinese Communist Party, Russia, and Belarus. The CCP is building and commissioning coal-fired power plants at a breakneck pace because it is the cheapest and most reliable source when emissions don’t matter.

The CCP has its hooks into corporate America, universities, and more. If we voluntarily price ourselves out of manufacturing with expensive, intermittent power, fully expect more manufacturing exports to the CCP. Global emissions would shoot higher, and we’d expose ourselves to the whims of Xi, like Europe to Putin.

Industrial Decarbonization Strategies

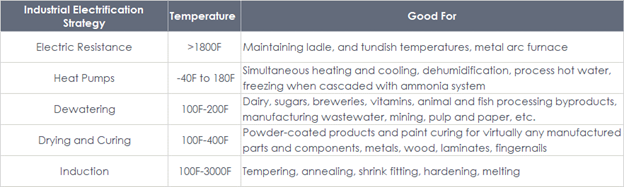

The Yahoo News article says the most readily electrifiable loads are in the 250°C to 300°C range (480°F to 570°F). I disagree because that is in the sweet spot for natural gas and would require electric resistance[1] as the alternative. Electric resistance at those temperatures is wasteful. Want to know where it is not wasteful?

Efficient Electric Resistance Heating

Electric resistance works well at very high temperatures, like 2000°F or more – temperatures needed for primary metals like steel. At those high temperatures, extraordinary volumes of natural gas must be burned first because the air used for combustion is about 80% nitrogen, the heating of which is a complete waste. Second, heating to high temperatures with natural gas wastes heat on heating structures and the surroundings where the process heating occurs (see induction below).

Heat Pump Leverage

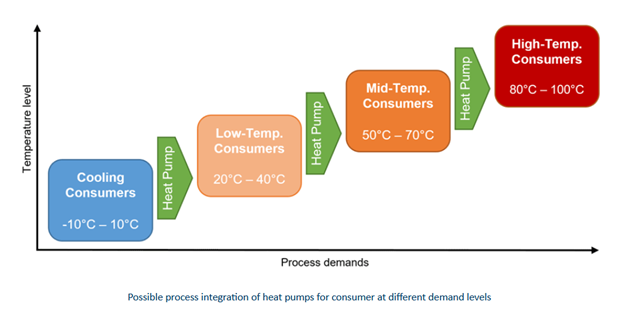

The other sweet spot for electrification is heat pumps for process water heating and space conditioning. You need refrigeration and hot water at the same time for your process? Heat pump. You need space temperature and humidity control? Heat pump.

Heat pumps provide heat and refrigeration simultaneously and are, therefore, a better option than, say, ammonia refrigeration for space conditioning and steam for reheating in a dehumidification scenario. This latter conventional approach burns the candle at both ends, wasting BTUs and energy, plus added carbon emissions.

The challenge with basic heat pumps is limited high and low temperatures. However, on the refrigeration side, they can be cascaded with other refrigeration loops like ammonia or CO2 to produce the coldest temperatures necessary. The cartoon from this Norwegian Blog provides a nice illustration.

Efficient Dewatering

Efficient Dewatering

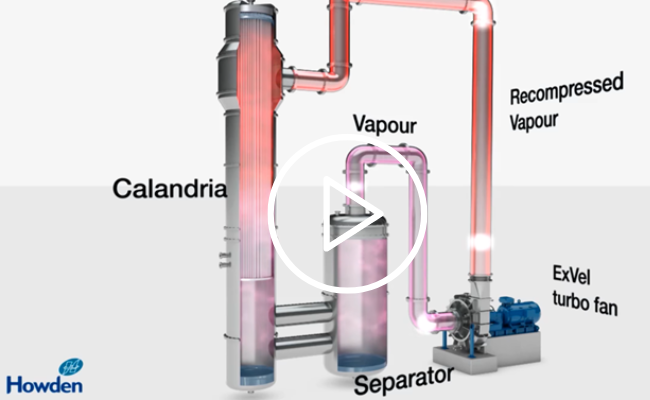

Another class of thermal (heat) loads that can be efficiently electrified includes dewatering. Dewatering is used for many things, from food processing to treating manufacturing chemical waste (cutting fluids). Rather than boiling water off at atmospheric pressure, use a compressor to take suction on the solution to decrease its pressure and boiling point, and use the heat from the compression cycle to heat the solution to boil off the water – it’s genius. This is called mechanical vapor recompression. Here is a nice, animated cartoon of the process:

Drying and Curing

Drying and Curing

The last application I’ll discuss this time is process heating as an alternative to heating a bunch of space and mass, as with paint and powder coating curing or primary metal processing mentioned above. Natural gas is a cheap source of BTUs, but we don’t want to heat tons (literally) of mass, like refractory and steel chambers, for these processes. Instead, use electrically charged infra-red for drying and curing paints and coatings. The benefits include instant on/off, speed, and precision for the process.

Induction

Electric coils are beautiful things used to change voltage in transformers, make homemade magnets, and induce electric currents (induction). Induced electric currents heat nearly any metal, including copper, aluminum, silver, and gold. This is the alternative to heating tons of structure, plus the process material, and saves massive amounts of energy and hydrocarbon combustion. It is instant on, instant off, and very fast.

Cheat Sheet

Cheat Sheet

[1] Or microwave or infrared -all about the same efficiency that is 1/3 to 1/5 of a heat pump.

Efficient Dewatering

Efficient Dewatering