In a previous brief, we discussed that the largest heat loss from a boiler is through the stack. An economizer can reduce these losses and increase the overall boiler efficiency by about 1% for every 40º that the exhaust temperature is reduced.

Is an Economizer Right for Me?

A stack gas economizer is a good fit for most boilers that meet three criteria:

1. High hours of operation. The economizer only saves during periods when the boiler operates. Therefore, in a multi-boiler plant, it may only be cost-effective to install an economizer on the lead boiler.

2. Potential for heat transfer. The cooler the exhaust is, the less heat there is available for recovery. A boiler with 350º F exhaust has limited potential unless a condensing economizer is installed. Also, small boilers may not be cost effective due to the limited savings potential.

3. A heat sink that can use the heat as often as possible, preferably all year.

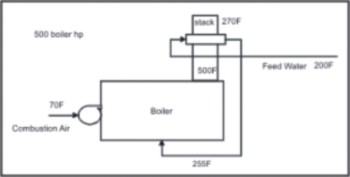

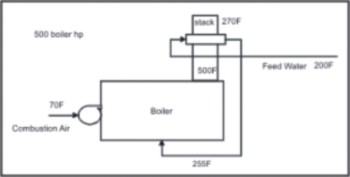

The easiest and most common heatsink for an economizer is the boiler feedwater (as seen in the figure). However, especially in low pressure boiler systems where all of the condensate is returned and the feedwater is hot (180º or more), the potential system efficiency increase due to the economizer can be limited to 1-2%.

If a system has direct injection steam needs, an alternative may be to preheat the boiler makeup water. The makeup water is colder than the condensate and therefore, can absorb more heat from the exhaust. This can be especially effective when coupled with a condensing economizer.

Condensing Economizers

With a conventional stack gas economizer, the exhaust temperature is maintained at 300ºF or higher to stay above the acid dew point. This limits the ability to improve the system efficiency, usually to around 85%. The acid dew point is the temperature at which the carbonic acids and sulfuric acids in the exhaust start to condense. These acids can eat away at the economizer, the stack, and in some cases, the boiler itself. Care must be taken when designing these systems.

A condensing economizer is constructed of corrosion resistant materials. Therefore, the exhaust temperatures can be reduced to 100ºF, or lower. Efficiencies of 90% or greater can be achieved.

Conclusion

Stack gas economizers can be one of the most cost effective improvements to a boiler plant. They are a great way to stop having your profits “go up in smoke.”