The batteries are coming! Maybe. I recently participated in an EPA-sponsored webinar to explore the results of a couple of case studies of lithium-ion batteries used to shave and shape building electrical loads. The technology is more nascent or even embryonic than I would have guessed.

Interestingly, I’ve read a lot about systems approaches to fighting the COVID – that is, our bodies’ systems to take on and ward off attacks by viruses effectively. I thought, wow, this is where we (Michaels) differentiate ourselves by thinking holistically, beyond the widget. Like many other technologies, such as combined heat and power, cost-effective utilization of battery storage for lowering peaks and shaping demand for buildings requires full-tilt asset utilization and control.

Cost-Effective?

The EPA, via the webinar, states that 25% of commercial facilities could be “cost-effectively” outfitted with battery storage to decrease operating costs. That is in quotes, only because it wasn’t defined. However, I find the percentage to be surprisingly low. I would say it is due to stable, consistent rates with low demand and energy charges – as opposed to more volatile rates that may only be available in competitive retail markets. Market-driven prices can be much lower, nearly all the time, but building owners who snooze through a heatwave may pay the piper and then some with excessive peak load contributions, or PLCs in those deregulated territories.

Think of smuggling beer or higher octane libations into college football games, when we had them, versus buying Bud Light in house. Prices are lower outside the stadium because of competition, time, and storage. Inside the stadium: no competition, high prices. The problem with batteries is the vessel, the battery, is very expensive for the stored contents compared to a flask for illicit schnapps. If that doesn’t take you back to your good old days, I can’t help you.

Operating Cost Savings

There are two ways in which batteries can reduce operating costs: reducing peak demand, of course, and arbitrage. “Arbitrage?” I thought. Arbitrage is something we try to do in the stock market: buy low and sell high. I wrote to the moderator during the webinar that I don’t know about California, but I can’t hook a battery to the grid here in the Midwest and take kWhs when wind-farm generators are paying people to take them, and then sell them in August. It doesn’t work that way in California either. What they really mean is, charge when prices are low, burn when prices are high. The result is the same.

Case Study

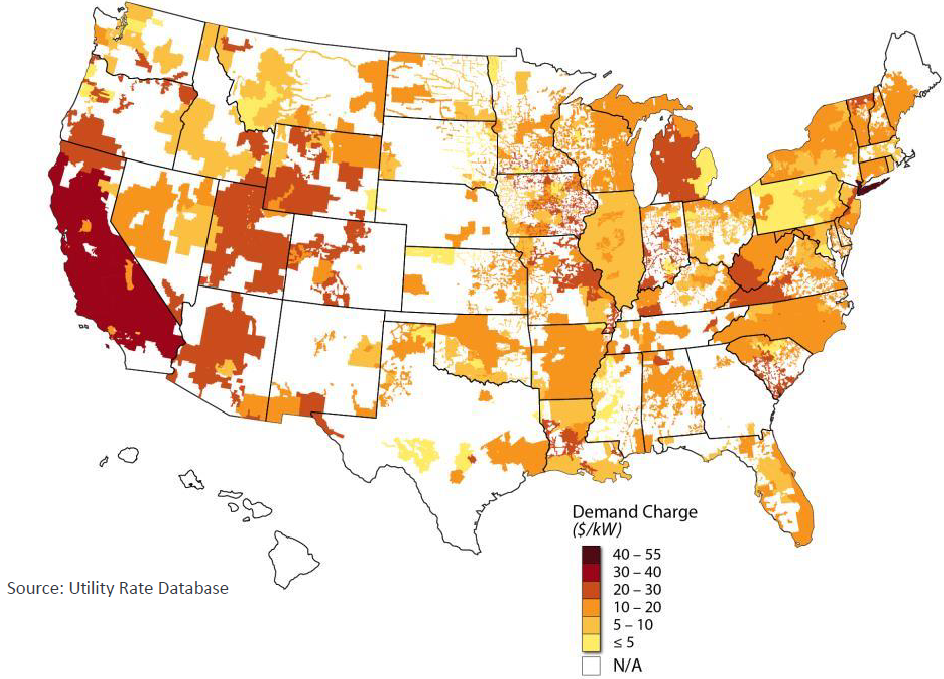

The EPA case studies included California commercial real estate properties. One included a new 1.25 million square foot high rise building in San Francisco. With average energy and peak demand charges of 25¢ per kWh[1] and $45 per kW, respectively, we have fertile ground and the best conditions possible for cost-effective batteries, one would think. If anywhere there were a risk for a flask, er, battery, this would be it. See demand charges below – higher makes storage more attractive.

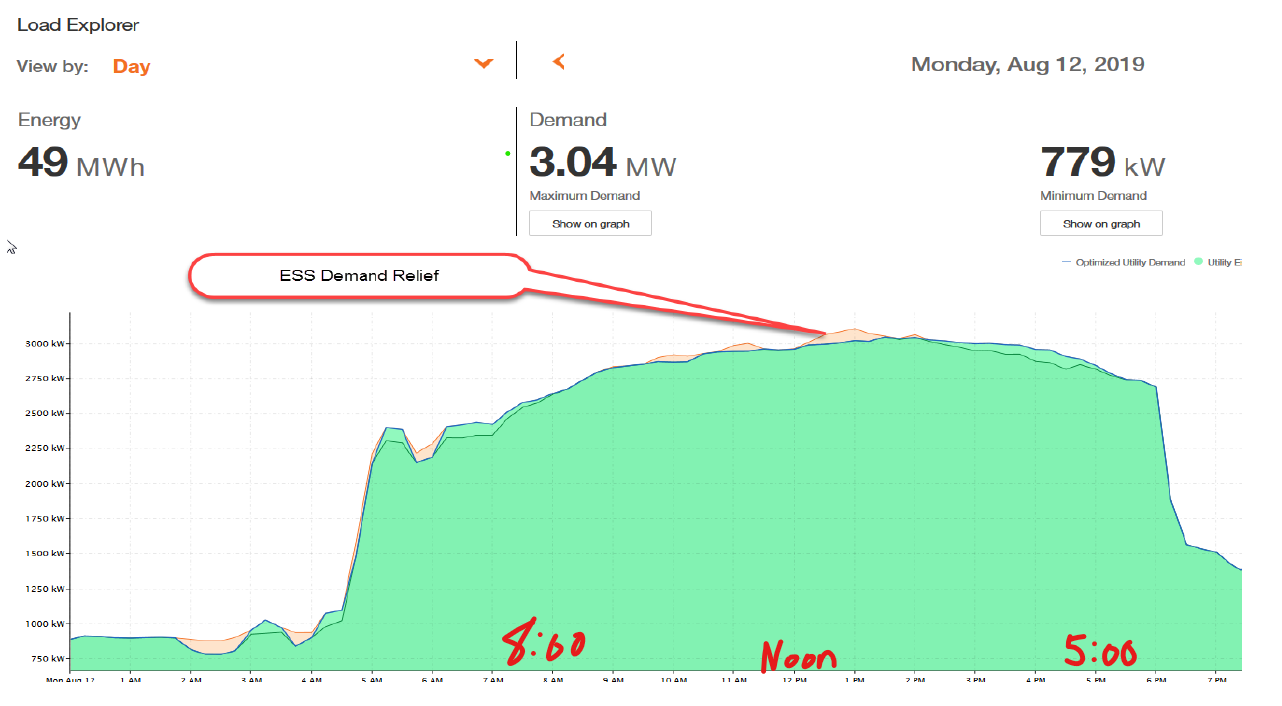

Once key metrics for energy performance are presented, I reach for my calculator. For instance, this facility has a peak demand of just over 3 MW, or 3,000 kW. I would expect a commercial office building to have a load factor, which is the average load in kW divided by peak load, kW, to be about 0.5. With 3,000 kW, a load factor of 50%, and 1.25 million square feet, the energy intensity would be about 10.5 kWh per square foot. That is pretty lean, even for San Francisco, and it’s superb climate for low energy consumption.

The building in the case study has a daily load curve that is quite flat, as shown in a screen scrape below. On August 12, 2019, the high temperature in San Francisco was 77F (about ten degrees warmer than average) likely driving some of the load shown, as it peaks just after noon. The 100 kW battery discharges as shown in the orange portions under the curve. The battery starts charging again between about 2:00 PM and 5:00 PM. Why charge in this on-peak period? I don’t know. The tariff wasn’t provided, but it would seem electricity would cost less in the middle of the night.

Tricky

Not surprisingly, we see that controlling a battery to optimally reduce operating cost is not straightforward. The load shape is a big factor. If it’s “peaky” with shorter peak demand durations, a battery can save a lot of billed or peak load contribution – PLC.

Furthermore, the peak load reduction only matters on the day with the highest demand during the billing period, and during the entire year, depending on the contract/tariff. It almost becomes a field goal kickers dilemma. Don’t blow it! The game is on the line. That could be the fourth quarter, overtime, regular season, or the playoffs.

For this case study, the facility saved only $10,000 annually, compared to a projection of $25,000 annually. Doing the math, the 100 kW battery at $45 per kW could reduce peak demand charges by $4,500 per month, but the duration of the peak is a sticking point. The peak load duration can be a killer for battery cost-effectiveness.

Homework

Other considerations:

- Batteries have a substantial footprint: e.g., 15 feet by 6 feet for a 100 kW unit

- They are heavy. Call your highly-compensated structural engineer.

- Fire marshals are not fond of them. Look out!

[1] Total bill, less fixed charges, divided by kWh.

I really enjoyed this piece – although I always preferred tequila over schnapps. I am an electrical engineer who designs systems for buildings in San Francisco and am currenly designing larger scale battery storage systems for buildings. The case study referenced sounds like a building I know on California Street in San Francisco. I think office buildings, in general, have fairly flat load profiles so untilizing 4 hour batteries to peak shave is tricky and really only effective with the right load profile. Thanks for your insight.

Thanks Susie. As I recall, at least one building was in SF. Speaking of tequila, I enjoyed a tequila bar in SF several years. back. I remember the smokey stuff… but agave is slow to grow and expensive, and therefore, tequila, expensive.