Energy efficiency program administrators can be quite conservative regarding change and innovation. I love hearing, “Bring us new ideas that have been successful in three or four other programs.” There you are!

The pinch is on. Energy efficiency codes and standards have raised the bar consistently such that incremental savings from one code change to the next are exceedingly scarce. The gravy-train days of incremental widget-efficiency improvements, including lighting efficacy and heating and cooling equipment efficiencies, are quickly closing.

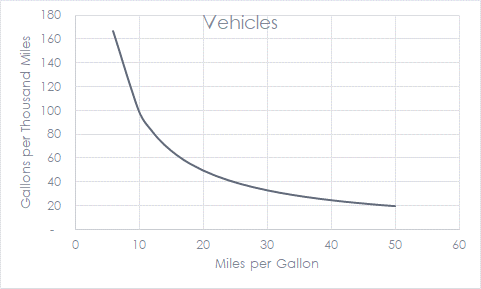

Vehicles

A nice parallel to diminishing returns on efficiency is vehicle mileage. The following chart shows fuel energy consumed per thousand miles for a range of mileage (efficiency). At the low end, we have the typical mileage of a long-haul freight truck at six miles per gallon. At the high end, saving fuel at higher efficiencies is increasingly difficult. Going beyond 30 mpg is expensive, requires a lot of weight shed, and maybe a battery-hybrid, and it doesn’t reduce much fuel consumption.

Buildings

Buildings

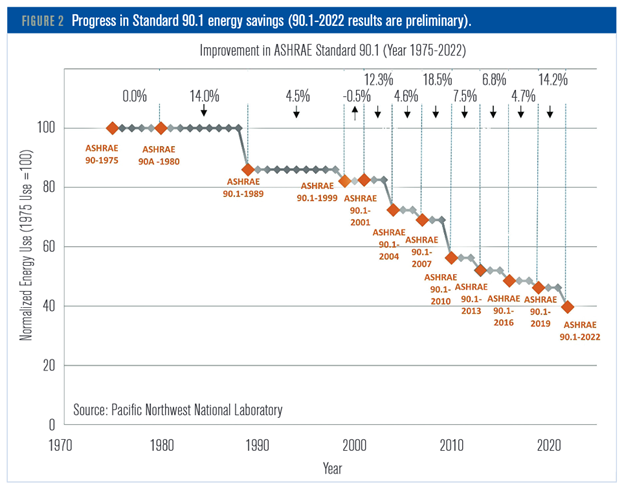

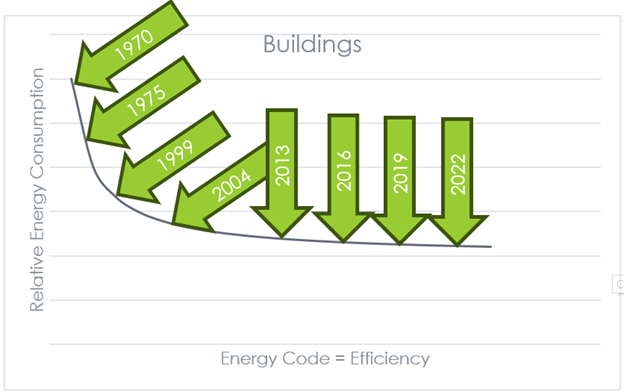

Building energy consumption curves are similar, especially when reality kicks in. The following chart shows theoretical energy consumption versus energy code, as defined by ASHRAE Standard 90.1, Energy Standard for Sites and Buildings Except for Low-Rise Residential Buildings. To be clear, the charts do not represent the same relationship. The above chart shows energy consumption versus efficiency, and the ASHRAE chart shows theoretical energy consumption over time. The ASHRAE chart is for new buildings and major retrofits.

Components

Components

Theory and reality are two different things. Widget efficiency as measured by efficacy (lumens per Watt), heating, cooling, and motor efficiencies measured as percentages, SEER (seasonal energy efficiency rating), and kW/ton, are reliable because there are testing entities like the Air-Conditioning, Heating, and Refrigeration Institute and Illuminating Engineering Society behind them. They provide uniform standards to ensure accurate and consistent methodologies for measurement. Widget efficiencies are out there on the tail of the curve, like the 30 mpg vehicles. It costs a lot to milk a few more kWh, therms, or gallons of saved energy by adding features and materials such as more heat transfer surface or levitating bearings.

Systems

The remaining coverage covered by energy codes, beyond equipment/component efficiency, includes systems design and controls – fitting the pieces together and orchestrating their operation. These parts are not lab-tested because their design and construction are distributed by hundreds or thousands of architect and engineering firms and mechanical, electrical, and control contractors. When adding the raw ingredients with the cooks in the kitchen, building performance likely takes the form of the vehicle performance as follows. The arrows represent years and ASHRAE 90.1 Standards. The first ASHRAE 90.1 Standard was in 1975 (major energy crisis – do something!). The second Standard was in 1989, the third in 1999, then in 2001, and every three years since, with the most recent being in 2022.

Taking on the Flatline

Taking on the Flatline

There are several ways to address exceedingly aggressive building codes. First, consider equipment and systems that are not regulated by energy codes. Second, take some free riders. Third, be patient. Fourth, adapt.

Systems and equipment not regulated by energy codes include manufacturing and industrial-like facilities, including data centers. I was recently part of a discussion with a data center expert. I knew of air-cooled and water-cooled servers but was intrigued by the emergence of immersion cooling. I was also surprised to find that data center owners/operators deploy a wide variety of HVAC technology, from lousy direct expansion cooling systems to chilled water with sophisticated economizer capabilities (various ways of using outdoor air to provide cooling without a refrigeration cycle). Those who chose air-cooled servers and direct expansion HVAC only care about first cost and maintenance – their people know how to maintain the equipment.

Taking free riders means incentivizing customers to be more efficient than the other guys or more efficient than code, even if that’s their standard practice. Why would you do that? To start a relationship. The message is that there is money here to help if you take it to the next level.

Being patient means testing some things and doing some pilots while collaborating with the customer and their design and construction teams. They just got some fat checks, so they know the program is serious. These industrial and industrial-like customers will not take anyone else’s word for it and dive in head first with the risk of paralysis due to a neck and head injury.

Implementation contractors must adapt to the customer’s process, interests, and timelines. It amazes me how some implementation contractors (ICs) treat major energy-using customers with the flexibility of the Olympia Restaurant, one of my first memories of SNL – hilariously stubborn. Oh well, let tens of GWh per year in impacts go wasted because the high-tech, unique customer has to fit the same process as a K-12 school district. Thank you! We will take those customers.

Program administrators and their ICs need to adapt to the long game, which also happens to be known as market transformation. This requires long-term engagements to understand how sophisticated (not necessarily large) energy users operate, how their business works, and what’s important to them.

Buildings

Buildings

Taking on the Flatline

Taking on the Flatline