Coils and Heating and Cooling Efficiency

In a recent LEED® Brief, “Dirty Coils and Fans,” we discussed the effects that dirty heating and cooling coils have on air handler fan energy. To recap, dirty coils that restrict flow in constant volume systems can many times decrease fan power, while dirty coils in variable air volume systems will likely increase fan energy consumption. In both cases, performance and air quality are compromised.

This brief discusses the effects on the heating and cooling equipment energy consumption. For brevity, we will only discuss cooling coils, as heating coils will experience similar effects.

Savings Potential

A quick review of web sites touting coil-cleaning systems indicates clean coils improve cooling efficiency by allowing for better heat transfer. One study indicates that decreased heat transfer is a loss – not really. As long as the coil is not so severely fouled that it can meet its load, typically by producing 55F air, there is no change in heat transfer. No “loss”.

Coil fouling with airborne particulate, and in the case of cooling coils, biological growth, results in effective insulation on the coil. This “insulation” reduces the capacity of the coil. As fouling increases, the heat transfer will decrease such that the coil can no longer meet the peak load for the space. Comfort conditions will deteriorate. However, the system will automatically counteract the dirty coil to deliver the cooling required, at the cost of more energy consumption.

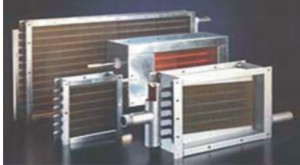

There are two types of coils: (1) direct expansion where the refrigerant boils at roughly 45F by heat absorbed from the air stream that is being cooled; and (2) water coils that use chilled water produced by a chiller.

In the case of a direct expansion coil, two things happen. The evaporator pressure and temperature will decrease because of the insulating effect of the dirty coil, and the heat transfer rate will decrease. As a result, the compressor will have to operate with a greater pressure differential and for a longer period of time to move the same Btus as a clean coil. Both phenomena will result in more energy consumption.

In the case of water coils, water flows continuously through the coil. Varying flow by throttling the control valve controls temperature. To deliver the same Btu/hr as a clean coil, the water flow will increase, effectively lowering the mean temperature of the coil. If the system has two-way control valves, the circulating pumps will need to move more water (water flow for three-way valve control systems will not be affected). This results in more energy consumption. Also, the chiller will see lower return water temperature, and like the direct expansion case, the average suction pressure will decrease, lowering the efficiency and capacity of the chiller to some degree.

Bottom Line

Keep coils clean. Air quality, both from a pollutant standpoint, and temperature and humidity control is the primary issue. Energy savings is an added benefit.