Coils and “Efficiency”

Many times companies that sell heating or cooling coil cleaning services or gizmos claim energy savings as one of the benefits. This is not always the case. For proof, turn your vacuum cleaner on and use your hand to plug the nozzle. The higher pitch you hear is the vacuum impeller running faster because the flow has stopped and the impeller torque has been reduced.

Fan and System Curves

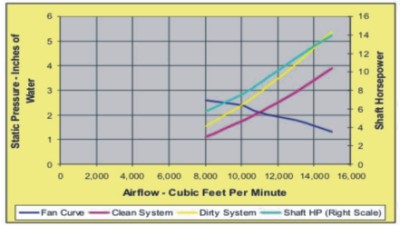

A fan wheel is a turbo machine with a given set of operating characteristics. These characteristics are dependent: a fan wheel operating at one speed will generate one and only one static pressure for a given flow in its working range. A plot of points with static pressure dependent on flow is known as the fan curve, which is plotted on the chart.

Similarly, constant volume systems consisting of an air filter, cooling coil, heating coil, network of ducts, dampers, and diffusers require one static pressure to produce one given flow. The flow produced by the fan operating in a system will be at the location where the fan curve (navy curve) and system curve (magenta curve) intersect. The flow is 11,000 cfm with 2.1 inches of static pressure.

When the coils become fouled, the “system” has been changed and the system curve shifts to the left. Now the flow at the intersection of the yellow (dirty) system curve and navy fan curve is 10,000 cfm with a static pressure of 2.4 inches of water. The flow has decreased, the static pressure increased, but the fan power (cyan curve) has decreased with the dirty coil.

Complicating Matters

The above example is for a constant volume system. Many large air-handling systems today are variable air volume systems with a variable speed fan. For these systems, the fan will speed up to provide the same flow at a higher static pressure. Indeed, in these cases, dirty coils result in more fan energy consumption.

There are several types of centrifugal fans indicated by blade orientation: forward curve (like the one above), backward curved, and air foil. Backward curved and air foil fans at constant speed operate at about constant horsepower, regardless of the flow. So once again, system cleanliness doesn’t necessarily mean fan energy savings.

We need clean systems for air quality and comfort. Energy savings are a secondary issue. Clean coils may require more fan energy or less fan energy depending on the design of your system and type of fan.

We will discuss the impact of coil cleanliness on heating and cooling efficiency in a future brief.