I would like to see a poll of peoples’ suggestions for decarbonization. My guess is solar panels would be near the top; next, maybe an electric vehicle; after that, maybe electrified appliances and HVAC.

Are any of these investments cost-effective? Keeping it simple, are the accrued savings over the life of the project or object more than the cost? It depends on the baseline alternative and various stackable incentives. Without guessing and getting into details, I believe consumer electrification and decarbonization are driven more by non-financial matters.

What about commercial and industrial facilities? It gets decidedly more challenging because the financials represent a much larger factor. What is the approach? Start with an assessment to identify and prioritize energy conservation measures. Pick the ones with the highest net present value to generate cash flow, and then move on down the list over time. At the same time, consider the remaining useful life of the energy-using equipment.

For example, let’s assume a campus of facilities like healthcare, higher education, or manufacturing. We will start with the heating and cooling plants and move down the line from there.

Introduction to District Plants

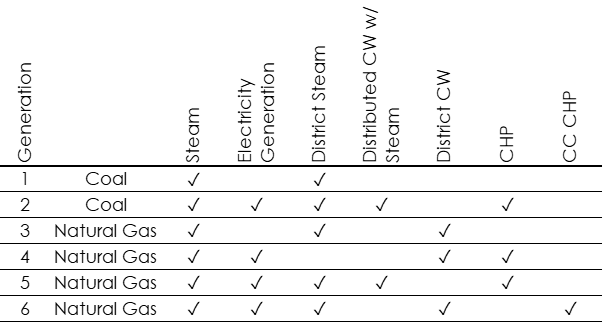

Campuses almost always have central or district steam and sometimes chilled water plants. In some instances, there are combined heat and power central plants. They generate electricity. The fuel may have been coal back in the day, but almost all of it has been transitioned to natural gas. There are many configurations serving campuses. I picked a few in the chart below, followed by their descriptions.

CW = Chilled Water

CHP = Combined Heat and Power

CC CHP = Combined Cycle CHP, discussed below

District steam and chilled water serve multiple buildings, sometimes hundreds of buildings.

Generation 1

The first-generation district plants were steam-only, fired by coal, and wasteful. For instance, when I was an undergrad at South Dakota State University, the grass over the steam distribution tunnels across campus was green in winter and dead brown by April. Dorm room temperatures were controlled by opening windows as needed to stay cool in the winter.

Generation 2

The second-generation plant produces much higher-pressure steam to generate electricity with a steam turbine. Low-pressure turbine exhaust steam is distributed to the campus for space heating and cooling. Steam-fed absorption chillers in buildings around campus provide cooling.

How does steam make chilled water? Absorption material, lithium bromide, has a strong affinity for water such that it will absorb it by drawing a vacuum at low pressure and temperature, resulting in chilled water. The steam drives the water out of the lithium bromide, and the cycle repeats. Click here for more details (steam or direct-fired natural gas shown in the video may be used).

Generation 3

The third-generation plant uses natural gas to generate steam and grid electricity to make chilled water for distribution to building loads on the district circuit.

Generation 4

The fourth-generation plant includes a low-pressure steam turbine to generate electricity upstream of the steam distribution system to the facility. I completed an assessment at a facility with a plant like this. It is substantially less desirable than the second-generation plant described above because of the low-pressure, low-efficiency turbine and because all chilled water was produced by electric chillers rather than steam absorption chillers. The result is poor alignment of electricity generation, heating, and cooling loads.

Generation 5

The fifth-generation plant is the same as generation two but uses natural gas as the fuel.

Generation 6

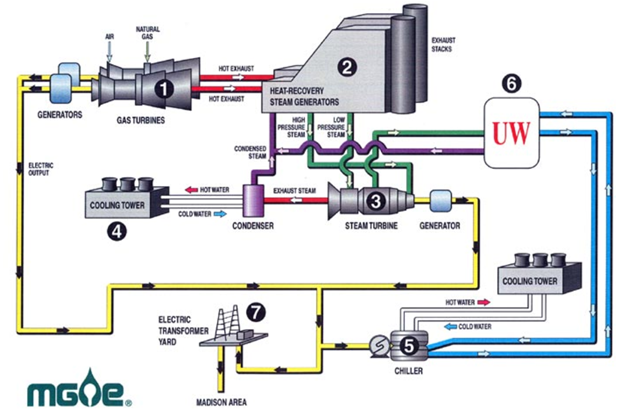

Finally, the sixth-generation plant is very efficient and produces very low net emissions. Madison Gas and Electric’s West Campus Cogeneration (CHP) Plant is an example shown below (love it when somebody else draws the cartoons).

This plant wastes very little of its source energy, natural gas. I don’t have the specifications of this plant, but I have educated guesses for them based on my research on power plant efficiencies in graduate school and lots of reading since. This plant is entirely fueled by natural gas.

- The topping cycle gas turbines (1) generate electricity at roughly 30% efficiency.

- The exhaust from the gas turbines is used to generate steam (2), to generate more electricity (3), again, at roughly 30% efficiency. Note the high and low-pressure steam lines to the turbine. This is an efficiency play to milk more high-value electricity from the fuel source, natural gas.

- The plant’s generated electricity drives centrifugal chillers at the plant (5).

- The plant supplies steam and chilled water to the campus (6) and sends the rest of its electricity to the city (7).

The only waste here is the heat going to the cooling towers, maybe 15-20% of the natural gas’s available energy – an excellent low-carbon means of heating, cooling, and electricity production for the city.

Generation X

These are just a handful of examples. The sky is the limit for other configurations in existence and possible designs in the future. Let’s move on with some thought teasers moving into next week.

Supply and Demand

How would we improve the efficiency of the West Campus Cogeneration Plant? To do this, we must think big picture: heating, cooling, and net (city) electrical demand, 8760 hours per year, while considering issues such as maintenance and reliability.

A significant waste stream I see is steam turbine exhaust going to the cooling towers. What if we replace about 30% of the electric chiller capacity with absorption chillers instead? Why would we do this? First, it would suck more energy out of the steam before the heat is rejected to the atmosphere. Second, steam loads on campus are lower in the summertime, so more steam turbine exhaust is used rather than electricity to generate chilled water.

However, I see a tradeoff in that strategy. Since more energy is extracted from the steam, less may be returned to the steam generator. It depends on the design, to which I am not privy. The tradeoffs are mind-boggling.

Another option to solve the low-summer-steam-demand issue would be to cover the nearby soccer fields with solar panels and see what the students think of that tradeoff.

Combining the operating parameters of the plant, steam and chilled water loads of the campus, and the value of electricity on the grid gets extremely complex. Ninety-nine percent of operating plants in the country have simpler and cheaper upgrade potential. We’ll get into some of those factors next week.