Every kilogram of marijuana produced has a carbon bigfoot print of 4.3 metric tonnes (4.7 tons) of CO2. Marijuana production (U.S) consumes the annual electricity production of 1.7 million homes. Marijuana production consumes 1% of the nation’s electricity, and it’s growing rapidly. Data centers consume 3% of electricity worldwide. Mother Jones reports a growth module that four measly plants consume as much power as 29 refrigerators – probably not even efficient ones at that.

Ok. Now that we have some context, you can bet this is a serious post.

Public Service Announcement

I can’t help but mention that older marijuana users were likely virulent big tobacco bashers 20-30 years ago. According to the American Lung Association, most marijuana is consumed by smoking it. The smoke has many of the same carcinogens as tobacco. Marijuana is inhaled more deeply with a longer hold time (sure, Bill Clinton) exposing users to greater risk, all else equal.

Here ends the PSA.

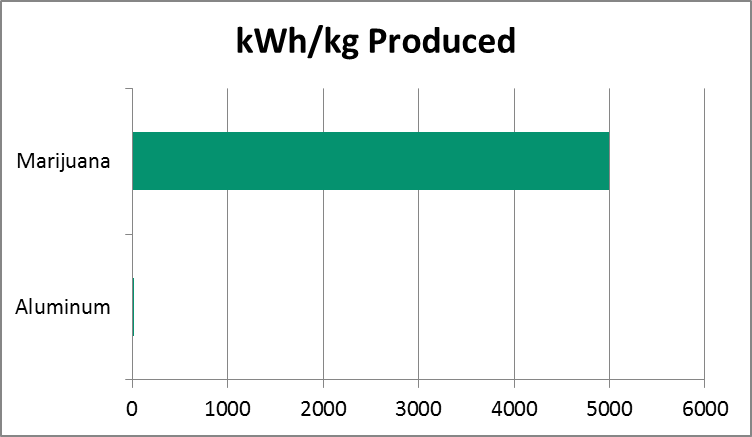

kWh/kg Produced

Utilities and Regulators Perk Up

Marijuana, and not the electric car, could be the load-growth white knight for utilities for years to come. Its production is giving the Pacific Northwest, Washington, and Oregon a freak out, and rightly so. In November of last year, Utility Dive reported Pacific Power experienced seven localized outages due to intense pot-growing operations. Seattle City and Light reported 3% load growth due to pot production. Utility Dive also reported that pot production was responsible for 50% of Denver’s load growth, last year.

Source: nwcouncil.org

Break It On Down

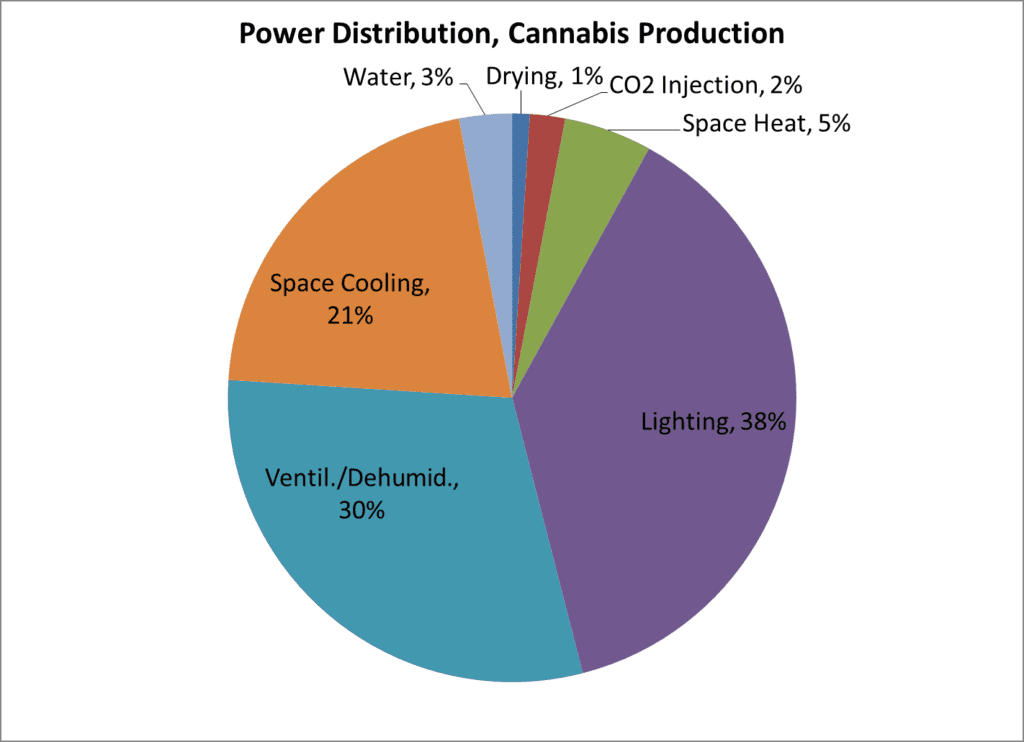

The Northwest Power and Conservation Council provides data for the following energy use breakdown of marijuana production. If you are a critical thinker like me, you’re wondering what the heck is wrong with the sun? More on this later.

According to a useful paper by E Source, with some of my own reading between the lines, pot growers are the ultimate fidgety, short-term investors. They scoop up old warehouses and outfit them with outrageously energy intensive equipment to control every aspect of production. One reason, I am sure, is to get going as fast as possible, just like any for-profit enterprise. In Colorado, Oregon, and Washington, the outdoor climate warrants indoor climate control. I am sure there were hundreds, if not thousands of (pun alert) budding entrepreneurs ready to launch out of the gate with the legalization of the substance. The fastest way into the game is to buy cheap facilities and pack them with artificial climate control equipment indicated in the pie chart above.

Other than the usual myopic, damn-the-torpedoes sprint into production, pot growers fear legalization will be repealed. As Dana Carvey doing George HW Bush would say “na ga da it”.

My interpretation of the E Source paper is that most likely our budding entrepreneurs moved their previously illegal basement operations, with their 10,000 kWh per month home energy bills (10x normal consumption), into these hermetically sealed warehouses. They blaze the plants with artificial light, and the plants give off lots of water vapor resulting in Amazonian conditions. They constantly need cooling because internal gains (lighting) more than offsets heat losses, even in cold weather. Hire an engineer or consultant to determine the appropriate cooling unit capacity? Fuggedaboutit. I’m going to crush that there ant with this here sledgehammer.

Growing Needs

To produce solutions for cutting energy bills and carbon bigfoot prints by probably 75%, I need some basic information. In what environmental conditions do our little gems thrive? Perhaps growers should consult with other indoor growers, say hydroponic tomato growers because I’m sure plants would do fine in the same conditions.

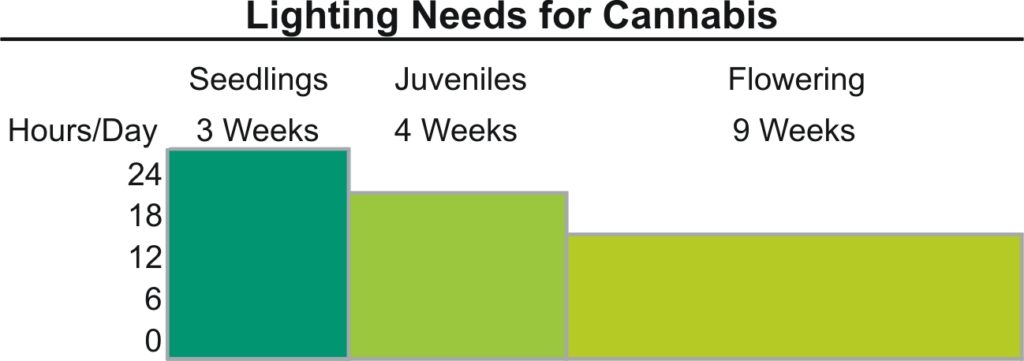

According to the E Source paper, plants have the following growth cycle and lighting-hour needs. The flowering stage, by the way is the harvest stage. The flower buds like capers are the product, although I have not heard of capers being rolled and smoked. As you might imagine, plants like temperatures from 70-85F with some natural cyclical variation. Growers want plants to grow as fast as possible in the first two stages, and then slow down for the harvest stage. Higher temperatures speed growth while cooler, dryer conditions slow growth. Like people, plants enjoy 50% relative humidity. We needed our IT people to loosen browser restrictions to get this information. Trust me.

Forecast

The cannabis industry will develop rapidly away from the illegal-production processes of “family farmers” to industrial production like anything else. Capital investors will run the little guys off the road.

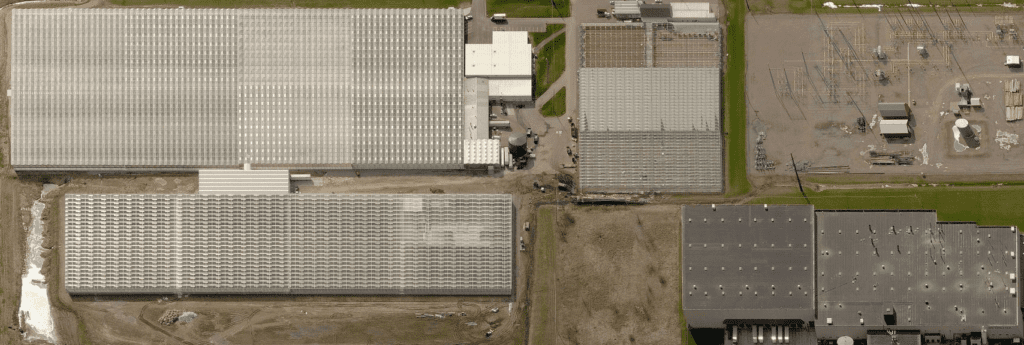

I can’t imagine why production wouldn’t expand to giant indoor greenhouses like those that already exist for fruit and vegetable production year-round. Operations will resemble something like Bushel Boy, the Owatonna, Minnesota based hydroponic tomato grower. Delicious, especially in the middle of Minnesota winters when they (pun alert) shine.

I may expand on this in a future post, but it seems like this may be a great opportunity for combined heat and power.

- Even the greenhouse growers have enormous power bills for artificial light.

- Humidity can best be controlled with ventilation, as with natatoriums, rather than mechanical cooling (refrigeration).

- Waste heat from the CHP unit preheats bone-dry makeup air as needed.

- Greenhouses need gobs of low-temperature heat, perfect for CHP.

- CHP produces CO2, which plants love.

I’m not going to give it all away, but these facilities need to mimic modern architectural trends – daylight, ventilation, natural flows, etc., rather than artificial everything in a sealed hermetic container.