A quick Google search for power factor provides the following definition:

“the ratio of the actual electrical power dissipated by an AC circuit to the product of the root mean square values of current and voltage. The difference between the two is caused by reactance in the circuit and represents power that does no useful work.”

This is a great definition that any electrical engineering professor would be proud of, but what does that really mean for the rest of us? Power factor is really a measure of how “in sync” an electrical signal is. It’s like having a strong connection with a colleague – when you’re in sync, you produce your best work. As shown in chart #1, the current and voltage signals exactly overlap and create the biggest power curve.

However, voltage and current are rarely in sync. Sometimes, when working with colleagues, things get out of sync. One (or sometimes both) has to work extra hard to get the same end product. This is like having a low power factor. In chart #2, the current signal has to be 20% bigger than the prior case just to get the same total power.

What causes it?

What causes low power factor? The quick answer is everything with inductive loads (motors and transformers) affects power factor. Inductive loads cause system amperage to fall behind the voltage signal, and ultimately lowers the power factor. This is like the second chart. This lag is especially bad for equipment that is lightly loaded.

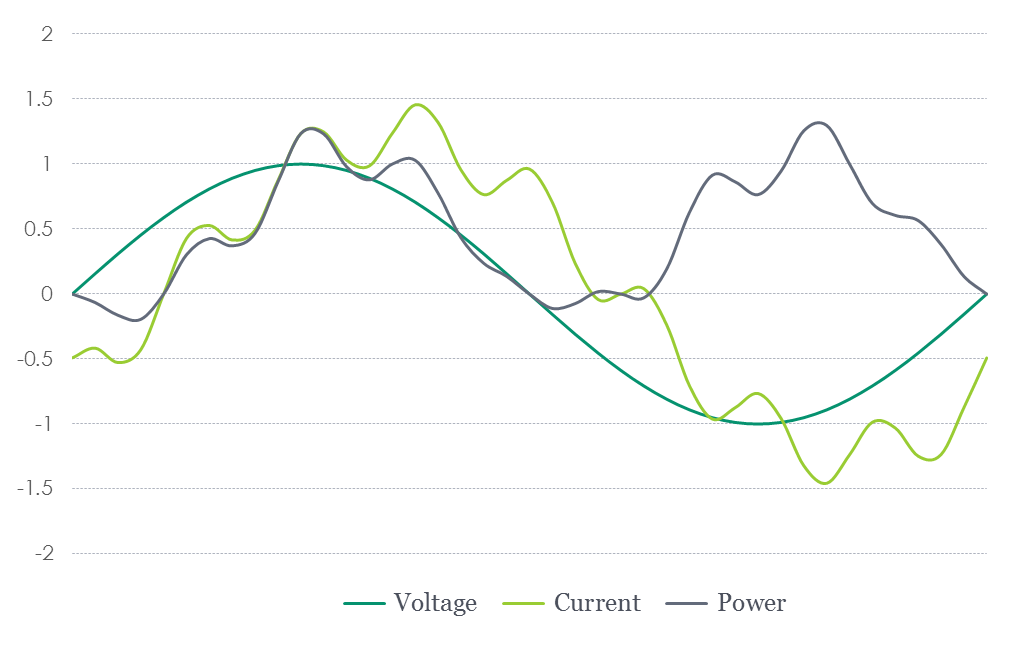

In addition, variable frequency drives, electronic lighting ballasts, and other electronic equipment chop up electrical signals and distort the signal, shown in chart 3. This distortion further reduces the power factor.

So does it Matter?

Having poor power factor doesn’t always matter. Energy and demand charges are calculated based on the actual energy used. This means that one kilowatt hour costs the same as if it was used with a power factor of one or 0.5. However, in many cases, utilities charge customers a “penalty” if power factor drops below a threshold of around 85-90% or so. These penalties can grow significantly, up to 25%, if power factor drops excessively low (below 70%). The reason for the penalty is that low power factor requires more electrical current, resulting in greater line losses, requiring more power at the generator.

Can power factor problems be fixed?

Low power factor problems can be corrected with active systems that monitor the current power factor and adjust accordingly, or passive systems that apply a continuous, fixed correction to the system. In addition, harmonic mitigation systems correct for low power factor issues due to signal distortion.

Installing a power factor correction system can result in lower electric bills and less energy consumption at the generator. At higher power factors, the loads, motors, and other equipment can be met with lower current levels. The lower current levels result in reduced resistive losses for all of the wires and other equipment. However, the energy savings are usually small. The main benefits for these systems is to eliminate any power factor penalties.