Everyone wants artificial intelligence to solve a big problem. Nations see it as the next arms race. CEOs see it as free labor. Vendors see it as a feature they can bolt onto anything with a circuit board. But somewhere between global dominance and nine hours of reclaimed employee time per week sits a rooftop unit humming on a strip mall, and that is where this week’s reality check begins.

As a product of the 80s, I remember the Tears for Fears song “Everybody Wants to Rule the World,” released near the peak of U.S.-Soviet nuclear armament. It isn’t literally the quest for world domination, but the general lust for power. Today, we can add two words to the song’s title, “with AI,” or is that three? You be the judge. Almost literally, governments, especially China v USA, think AI is the next Cold War that must be won at any cost.

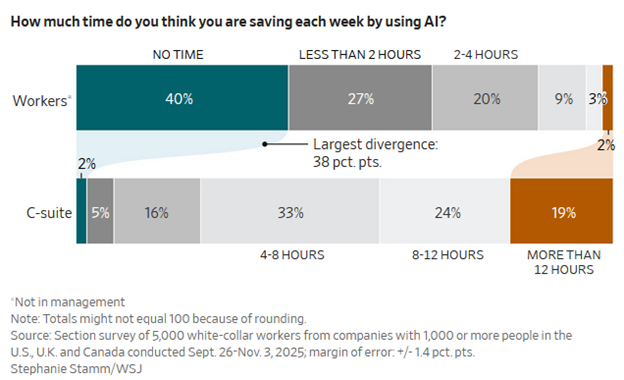

Meanwhile, CEOs[1] are telling their employees that AI is making their lives easier and freeing up their time. The Wall Street Journal reported the disconnect between workers’ and C-Suite opinions on AI’s impact on workplace efficiency, as shown in Figure 1. Doing a little head math, about three-quarters of CEOs think AI is freeing up a little over nine hours of employee time per week. How do you like sleeping in every day for a couple of hours compared to the Stone Age of pre-2023?

Figure 1 Perceptions of Time Saved by AI

Artificial intelligence hasn’t decreased my load at all. I can produce more or produce things faster in some cases. It’s especially good at synthesizing a lot of my rambling writing, developing complex projects, and then troubleshooting and tweaking, because all the context is there.

I have also learned AI’s limitations and how amazing human brains and bodies are. I listened to a podcast on robot development with Elon Musk last fall, and I remember how he described the human hand as incredibly complex. Now, when I unload the groceries from the car and determine how many bags I can carry with two hands, plus the leash and dog vest, fob, and gloves, and whether I really need to set a bag down to unlock the door, I appreciate what he had to say about that. Likewise, I recently learned how to play a few new card games, and I wondered, how long would it take AI to figure that out? Or developing a robot to shuffle cards like a pair of hands? What would it sound like? AI gave me an answer “frrr-tktktktktktk-frrrap.” There you are. Almost home.

AI and HVAC Systems

With that prelude, let’s explore AI and building automation systems. Like the, uh, CEOs above who don’t really understand AI (not that I do), be wary of peddlers of AI-enhanced automation systems. AI is not a magic wand, and it does not pair well with custom-built mechanical systems, which is precisely what heating and cooling systems are. AI itself gives us this succinct explanation: The part people skip over when they say “AI will optimize buildings” is the brutal, unsexy prerequisite: clean, calibrated, high-resolution, trustworthy data from systems that were never designed to provide it.” AI is not necessarily the problem. It is a hardware, commissioning, maintenance, and human discipline problem.

To have a chance, AI and control systems need accurate data:

- Airflow measurements

- Supply and return temperatures

- Static pressure

- Damper positions

- Valve positions

- Real-time power draw

- Occupancy patterns

- Weather integration

- Equipment health diagnostics

- Clean trend history

In reality, we find:

- Broken temp sensors reading 32 degrees year-round

- Dampers stuck at 60 percent

- VFDs overridden in hand mode

- Blocked occupancy sensors

- Controls sequences that no one remembers writing

- Trend logs turned off to save memory

For AI to optimize energy performance, the system must be obsessively and perfectly instrumented. If that state of nirvana can be achieved, a conventional building automation system should capture 98% of the potential savings or optimization.

Scale

Another factor that affects the cost-effectiveness of AI is scale and repeatability. As noted above, HVAC systems in large commercial buildings are practically like fingerprints. It’s not scalable. It’s not like AI for self-driving cars that could displace the 300 million conventional cars in the United States. That is a scalable application for AI; HVAC systems? There are 15 million packaged rooftop units operating in the United States. Not bad, but do we really need artificial intelligence to optimize a crappy rooftop unit? It would be like hiring a neurosurgeon to extract a sliver. A rooftop unit is a sheet metal box with a fan, a compressor, heat exchanger coils, some dampers, and a thermostat that has probably been in override since the GW Bush Administration. The control problem is not a geosynchronous orbit calculation. It’s a “give me heat, remove heat, on/off, open/shut” device.

Figure 2 York Rooftop Units

Our engineers have analyzed the results of AI-driven HVAC control solutions, and my summary of their findings is that there have been some scheduling optimizations. My Nest thermostat did that back in 2013.

The human brain is incredibly intuitive and adaptive, especially when trained by a ham. As I explained to my physical therapist last week, his job is safe from AI. AI will never replace the amazing skill of sight, touch, measuring motion, or jabbing a dozen needles into my pelvic area and legs and lighting them up with electrical pulses.

Similarly, but maybe not to that extent, ham-trained engineering jobs are safe from effective energy assessments and retro-commissioning studies. There won’t be a Waymo replacement for an effective engineer because variables and the sensory inputs are infinite. A computer will never replace the senses a human has in a building: touch (temperature, wind chill, vibrations), sound (air noise, machine noise, vibrations), smell (“burning,” dampness – mustiness).

Mechanical HVAC systems that move and control the flow of air, water, and refrigerant experience the following:

- Wear

- Loosening

- Corrosion

- Siezing

- Drifting

- Get plugged with debris and particulates

- Are overridden by a guy with a screwdriver

A ham-trained engineer can walk into a mechanical room and in a minute or two detect:

- Imminent bearing failure

- Flooded drain pans

- Slipping belts

- Air balance problems

- Stuck valves

- Short-circuited air flow

- Inadequate or excessive ventilation

A Waymo auditor would require customized multisensory inputs, which would be cost-prohibitive. Supposing cost were no objective, once you get there, you would have built a nuclear submarine to control an HVAC unit.

As my boss used to answer every question that started, “Is it possible to…,” yes. It’s only a matter of money.

The bottom line is that a drone can probably navigate a building, collect data, feed it into an AI-generated engine, and produce an outcome. Expect the results to look like Mr. Potato Head assembled in the dark.

[1] Not including this one.