Don’t Overbuy

It isn’t customary to walk into a car dealership and request the largest or most expensive car on the lot without regard to what kind it is or what it will be used for. A carpooling parent, a long distance commuter, and a landscaper all have very different vehicle requirements. Similarly, individual compressed air systems have different requirements and needs. While variable frequency drive (VFD) air compressors can be an efficient replacement for constant speed modulating, variable displacement, or load/no load compressors in some circumstances, it is not always the most efficient or cost-effective option.

Determine What Model

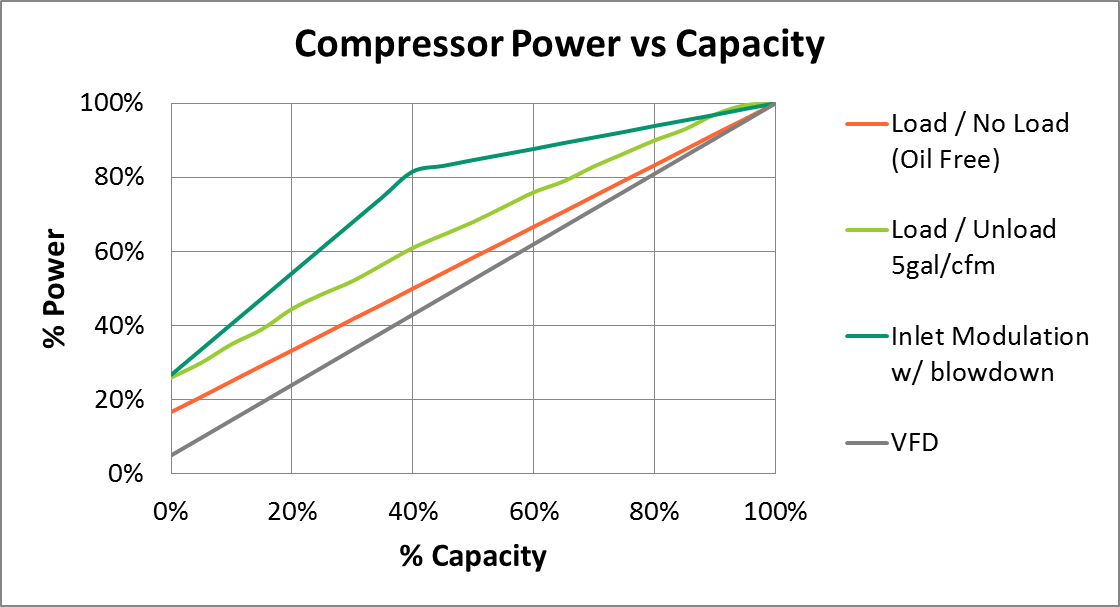

A long distance commuter puts on steady miles day after day at the same highway speed. This is similar to a compressed air system with a consistent load profile. A VFD compressor for this type of system would be an expensive investment. Choosing a fixed speed compressor to operate at near full-load with an efficient motor not only saves capital costs initially, but operating energy costs as well. Air compressors with a VFD are typically the most expensive type when comparing similar sized equipment. Also, the addition of the VFD on the compressor increases the compressor power draw when heavily loaded.

The hard working landscaper needs a vehicle to haul heavy loads of stone to one job and bushy magnolias to the next, with long breaks in between. For a compressed air system with high flow demand one hour and low demand the next, a compressor with load/no load or on/off control may be more cost effective options. Oil lubricated load/no load compressors with adequate storage can be nearly as efficient as VFD compressors, often at a lower cost. Oil free load/no load controlled compressor efficiency nearly rivals the efficiency of VFD compressors. And on/off controlled compressors automatically turn off when the system pressure is met, drawing no power at all.

A carpooling parent needs a vehicle that is versatile and seemingly never stops moving. The vehicle needs to vary from needing extra seating for kids after the soccer game, shuttling a few kids to swim lessons, or a solo trip to the dry cleaner. For compressed air systems with highly variable air demands, VFD compressors tend to be best suited for the role of lead compressor. The VFD compressor can handle most of the variation by itself.

Consider All Options

In the end, the air flow demands need to be evaluated before automatically upgrading to a VFD compressor. Often times, there are other ways to improve the system efficiency without a VFD compressor. Efficient staging of compressors, adding pressure control, and ensuring there is adequate storage are all non-VFD options for improving compressor plant efficiency.