What’s with the iced coils?

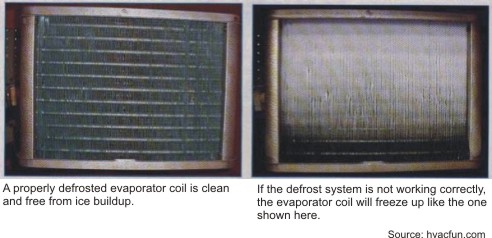

Whether you know it or not, cooling coils in a refrigeration system go through a defrost cycle to remove the frost buildup from the frosty coils. In coolers, this process can be as simple as stopping the refrigerant flow through the coil and continuing to let the fan run. Since the air temperature in a cooler is above freezing, the warmer air will melt the frost.

In freezers, some sort of heat input is required to remove the frost since the air in the space is below freezing. One option is to use electric resistance heating to melt the frost. Another option is to utilize hot gas from the refrigeration compressor for defrost.

Impacts of keeping them clean

Unfortunately, there is a double penalty for running a defrost cycle. Not only is there energy required for the defrost process itself, but defrosting also adds heat to the refrigerated space and therefore additional load on the refrigeration system. The defrost cycle heats up the evaporator coil and surrounding air to melt frost and ice buildup. This will need to be cooled back down to the refrigerated space temperature. Because of this, it is desirable to minimize the amount of defrost cycles and the duration of each cycle.

Possible solutions

Typically, defrost cycles are triggered by a time clock multiple times per day. The defrost cycle then runs for a prescribed amount of time set by the time clock. Instead of allowing the defrost cycle to operate for a set period of time, a temperature sensor can be installed at the outlet of the evaporator coil. Once the air leaving the evaporator coil is sufficiently above freezing, all the frost should be melted, and thus the defrost cycle can be terminated.

Another method to lower defrost energy consumption is to minimize the number of defrost cycles. Some other options for initiating a defrost cycle besides time include: measuring air pressure drop across the evaporator coil (more frost = more pressure drop), measuring the evaporator fan power draw (more pressure drop = less power), measuring the temperature difference across the coil (more frost = less heat transfer), or sensing the frost thickness directly with high tech sensors. One final, and reliable, method for initiating defrost is to monitor the time that the refrigeration solenoid valve on the evaporator is open, and initiate a defrost cycle once that accumulates to a certain amount of time.

Each of these technologies has positives and negatives, but the key take away here is minimizing the amount and frequency of defrost cycles maximizes system energy performance.