Two weeks ago, I described how liquid-air energy storage systems work. Concisely:

- Electricity drives air compressors that compress air to rather extreme pressures. This air compression generates a lot of heat, which is the lowest form of energy.

- Heat is stored in certain media.

- The compressed air is cooled, using electricity, until it condenses into a slurry of nitrogen, oxygen, and trace gases.

- The energy is recovered to produce electricity when the pressure is released and the stored heat is used to boil the liquid air to spin turbines and generate power.

Efficiency Defined

The industry uses the term round-trip (RT) efficiency for electricity storage systems. For storage or any other purpose, efficiency is the desired output or result divided by the required input or cost. Thousands of engineering theses, including mine, have been completed studying efficiency. The RT efficiency for storage is the energy (electricity) released during discharge, divided by the energy required to charge the storage media.

Electricity Storage Benchmarks

As tabled in the Liquid Air Yin Yang post, the RT efficiency for technologies ranges from 30% (hydrogen electrolysis) to over 90% for lithium-ion batteries. I wrote that anything below 90% is poor. Pure liquid-air systems operate in the 50-60% range. Some get a boost to ~70% by cheating and using natural gas to fire more energy released from the boiling and expanding air.

How bad is 50% RT efficiency? In airline terms, it’s like a round-trip flight to DC during the government shutdown:

- The TSA wait was two hours

- The arrival was four hours late

- The return flight was canceled

- The cost to get home was an additional $500, incurred after a two-day delay.

- The only thing running on time was the airport bar tab and complimentary trips to the head.

Now, ready for a first-class experience, with wine before departure, a decent meal, on-time arrival, and mirror that on the way home? Good, because that’s what round-trip efficiency with sundry benefits looks like with the proper thermal energy storage.

Stink Eyes

Engineers and other STEM professionals may raise a little eyebrow, or one brow up and the other down, when they ask about the RT efficiency of thermal energy storage (TES) and I tell them it’s over 100%. How can this be? A second law reverser? Absolutely not. It’s purely within the first and second laws of thermodynamics.

If you want to know what a second-law reverser is, cartoon physics is the best way. See this classic from Wile E. Coyote. Wile E. would be better off losing the sail and turning the fan around for propulsion, lithium-ion battery pack not included.

Control Volumes

In the engineering world, we use a control volume to model a system and apply the first law of thermodynamics, which is the conservation of energy. A refrigerator may be the control volume. When the door is closed, as when you’re on vacation, electricity passes through the control volume, turning the compressor, which compresses the refrigerant. The refrigerant gets hot and the heat is rejected to the room, across the control volume. That’s it. Electricity in, heat out to keep the refrigerator contents cold. There is no second law reverser. As I said last time, it won’t work unless you plug it in.

Now, consider a bottle of water in the freezer section of the refrigerator. Check out this video of stunning content for more. If you put a bottle of soft water in the freezer, it turns into hard water, also known as ice. Then, if you pull the plug on the refrigerator, the ice will eventually melt as it absorbs heat entering through the insulated refrigerator containment. Plug in the refrigerator, and the soft water turns to hard water once again. From the bottle’s perspective, there is zero loss. It uses no energy. It releases and absorbs energy without a battery or other power source.

Bottles of water are the essential storage media in a TES system. Unlike electric batteries, they consume (waste) no energy when they are charged and discharged. At the volume, they are 100% efficient. But this isn’t the end of the story, of course.

The storage media needs a refrigeration system to charge it. This is how and where TES RT efficiency exceeds 100%.

Actual Game Changing

With TES, the storage media provides a means to change the game in the owner’s favor. Is this cheating? Hell no. It’s like introducing the RPO (Run Pass Option) plays to the modern-day 1990s way of playing Wisconsin Badger football, which sucks, by the way. They’re stuck in the 1990s, thinking the Ron Dayne days are eternal.

There are two game changers for TES: 1) refrigeration compressor efficiency improvement and 2) boundary condition improvement.

Industrial refrigeration systems use the same vapor compression cycle to move heat uphill. Still, these systems are far more sophisticated than the home refrigerator or frozen novelty case at home-improvement store checkout line. The latter cycle on and off many times a day, while the industrial system runs partly loaded all the time – unless there is storage!

Game Changer #1

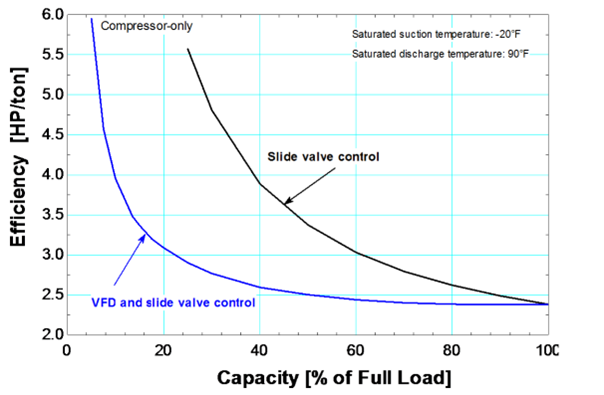

Partially loaded compressors are generally less efficient than fully loaded compressors, provided the same conditions (pressure lift) are met. I pulled data from our library of over 6,000 refrigeration compressors and plotted it in Figure 1. The plot shows efficiency upside down, or the cost in brake horsepower[1] (BHP), versus the desired output, refrigeration in tons of cooling[2]. The more loaded these positive-displacement compressors are, the more refrigeration is delivered per kW of electricity.

Figure 1 Part-Load Efficiency Screw Compressors

Figure 2, from our friends at the University of Wisconsin Industrial Refrigeration Consortium, shows similar results for the old-school throttling control versus variable speed control. Variable speed control (VFD = variable frequency drive) is considerably more efficient but offers declining efficiency as the load is reduced.

Thermal energy storage enables the refrigeration compressors to take a siesta for several hours rather than following the variable load. When charging the media (water) occurs, the compressors operate at their optimal efficiency near full load.

Figure 2 Part-Load Efficiency Screw Compressor – Slide Valve v VFD Control

Game Changer #2

Now for the boundary conditions: In addition to calling the shot like Michael Jordan to run compressors fully loaded for maximum efficiency, TES moves charging time off-peak, when guess what – outdoor temperatures are cooler. That’s like moving your refrigerator to the garage in wintertime.

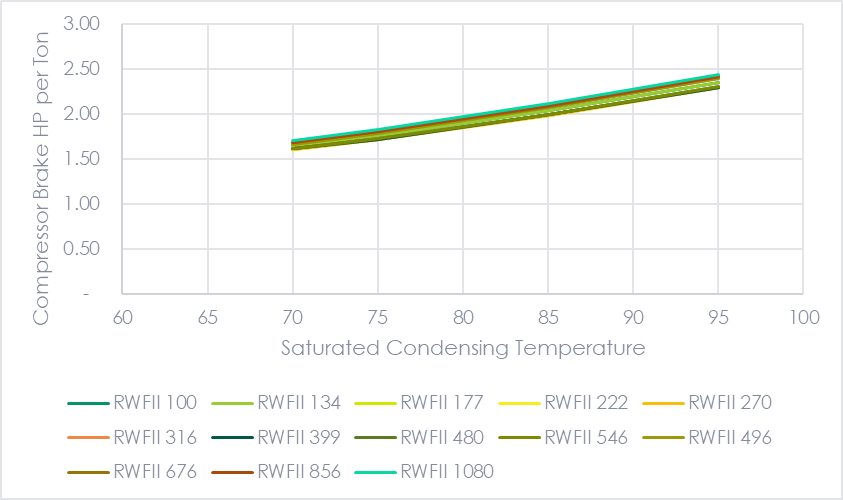

Figure 3 illustrates how compressor efficiency improves as the condensing temperature, which is directly related to the outdoor wet-bulb temperature (assume temperature – I spare the gore). Compressor power drops about 0.028 BHP per ton per degree Fahrenheit of cooler outdoor conditions. It adds up. Depending on the local climate, energy savings run around 15% for an ammonia refrigeration system.

Figure 3 Compressor Efficiency versus Condensing Temperature

RT Efficiency at the Right Control Volume

Flash back to the control volume. Expand it beyond the refrigerator to every point on the grid that supplies it with power. At that level, the RT efficiencies of the storage technologies in Table 1 from the Yin Yang post two weeks ago are accurate as shown. At that level, the RT efficiency of refrigerated cold storage with IceRack is on average 115% and consistently exceeds 100%.

Football spike here.

[1] BHP = normal horsepower, like the 502 HP in the Porsche 911 GT3

[2] A ton = 12,000 Btu/hour, about three of which keep your home cool during peak summer cooling. In this case, the refrigeration provided is at ice cream storage temperature of –20F.