Having seen several interesting emails form ACEEE come through during my uber busy week, one of the first things I did as I sat down to pound out this blog Saturday was to take a look and see what they were all about. This one discussing the virtues of the Clean Power Plan for manufacturers caught my eye. That led to many resources for combined heat and power, which of course can be a great tool for fuel efficiency and GHG reductions. That reminded me of this excellent evaluation paper reporting the findings of combined heat and power (CHP) installations. The paper is courtesy of our friends at Itron.

A couple weeks ago in Distributed Energy – Batteries and Bread Machines, I reported some cautionary statements about the purported tsunami of distributed generation in the form of rooftop solar and battery storage. To recap, one theme from that post: why would I want to buy and maintain my own micro power plant along with the associated headaches when Xcel Energy does a wonderful job of providing reliable power for many months at a time without interruption – and without hassle?

One of my conclusions from the Itron paper is that the buyers of combined heat and power plants do not understand the entirety of what they are buying, and they may not understand the best fit and applications.

As for the applications, I explained characteristics of best fits about nine months ago in Combined Heat and Power Ins and Outs. Characteristic #1: end user needs heat in a form that can be provided by CHP all the time. Characteristic #2: end user needs a lot of heat all the time.

- Best fits: manufacturer that needs a lot of hot water or steam 24/7/365.

- Poor fits: space heating only.

I suspect that many of the CHP buyers whose projects were analyzed in the Itron paper were sold on the benefits with little regard to these facts. When we have this perfect application with the need for a lot of heat all the time, the simple payback is going to be in the 6-7 year range. That is the best case.

What the paper really sheds light on is maintenance. Combined heat and power and distributed, behind-the-meter, generation and puppies have something in common – they require a lot of work and attention. (Shown nearby is our new addition, Lilly, and if you like what you see, vote for me, AESP Board of Directors)

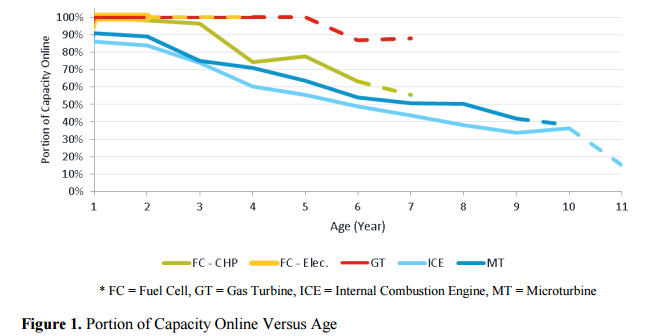

The typical useful life of a combined heat and power plant is about 20 years, per the Itron paper. Figure 1, from the paper shown below, shows the percent of capacity that is online and operational. Note: this is capacity that is online; not indicating the utilization or capacity factor of the online CHP plants.

Figure 2, Capacity Factor of Online Capacity Versus Age, from the paper shows the capacity factor for those plants that are actually online. The definition of capacity factor follows Figure 3.

Capacity factor is the electrical energy produced by all online CHP plants divided by the energy they could provide if they were all operating at 100% output all the time. In mathematical lingo (see equation/Figure 3):

The summations cover 370 plants; so this is no trivial data set. The capacity factors at year ten for microturbines and internal combustion engines are a measly 12% and 8% (percent online times the capacity factor for those that are online). Ten percent! That is pretty awful, I would say.

The thing is, these machines and puppies take a lot more maintenance cost than uninformed folks would ever guess. The first cost for a puppy varies from zero to thousands of dollars. A typical cost might be $500-$1000 for the average K9 shopper. Dog owners should expect to burn through this purchase price in maintenance cost by year three. Catch Lyme disease or blow out an ACL joint (for the dog), and you spend double or triple the purchase price.

Consider the IC engine in your car. You might drive 15,000 miles per year, possibly averaging 50 miles per hour with a mix of city/town and freeway driving. That is a measly 300 hours of operation with an average of very light loading. Meanwhile, an IC engine driving a CHP plant is heavily loaded and burns through 300 hours in less than two weeks. Two weeks!

According to the Itron report, microturbines require more frequent overhauls than IC engines (4-6 years). Larger gas turbines have slightly longer overhaul frequencies compared to IC engines. These are overhaul periods and not routine maintenance, like oil changes that are required much more frequently. Overhauls are major events – tearing the prime mover (engine) completely apart for inspection, maintenance, and replacement of parts. Note, these overhaul periods are shorter than the simple payback periods.

I look forward to a similar report when all those cell phones, er PV panels and battery packs have been in service for 10 years. Come to think of it, cell phones last about two years and then they are tossed for an upgrade. How does that compare with distributed generation, energy storage, and electric cars?