Static Pressure Reset – What is it?

Due to components such as coils, filters, and diffusers, all air distribution systems are resistant to airflow to some degree. To overcome this resistance, fans produce enough pressure to transport air to conditioned spaces. In a variable air volume (VAV) system, when a terminal unit damper begins to close, airflow is decreased and pressure in the duct increases. In these systems, fan speed is typically controlled to maintain a constant static pressure under all conditions. This pressure set point is determined as the minimum pressure necessary to transport the air to the most remote location under design conditions (this is typically when all VAV boxes are fully open).

At all other conditions, the fan is supplying greater pressure than necessary and energy is wasted. Some of this waste can be mitigated by implementing a static pressure reset control strategy.

How Does It Work?

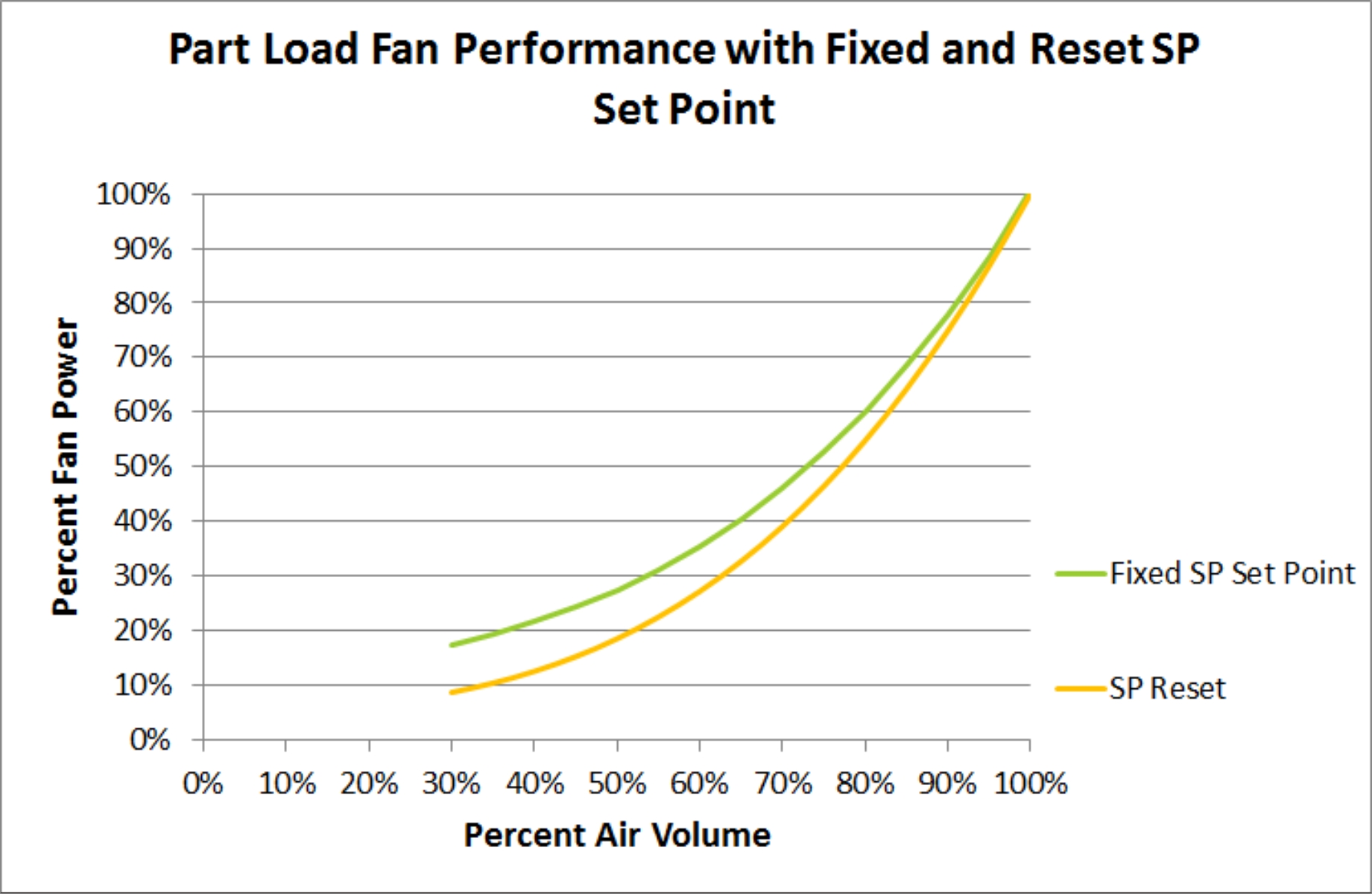

In a pressure reset strategy, the set point is adjusted, or reset at regular intervals to only be as high as needed to satisfy the zone of highest airflow demand. Fan speed is adjusted to meet the lower pressure set point. The reduction in pressure is proportional to the reduction in fan horsepower required. As shown in the graph below[1], a reduction in fan power of 10% or more can be expected under certain part load (or low flow) conditions.

Control Considerations

So, the physics make a great case for static pressure reset; however, there are control system requirements to consider. This strategy is only effective with a direct digital control system with VAV damper signals from each zone. It is also important to isolate any “rogue” zones from this control strategy. A rogue zone is one that is always calling for maximum airflow. An example is a data center, which essentially has a constant cooling demand. If a particular zone is constantly calling for design airflow, no pressure reset is possible.

Conclusion

The energy savings to be realized from any reset control strategy is ultimately determined by the amount of time the system operates at part load. Obviously, such an operating profile is unique for each air handling system. However, given the highly variable loads inherent in most variable air volume applications, it is reasonable to expect considerable energy savings in many systems.

[1] Energy Design Resources (Design Guidelines for VAV Systems), Appendix 5 (DOE-2 Fan Curves)