When purchasing a piece of equipment, you want to buy the most efficient equipment possible, so be sure to do your research.

Commercial and industrial equipment efficiency is almost always expressed at full load or at one operating point, typically whatever operating condition produces the best results. Consider efficient boilers. Nameplate thermal efficiency of a boiler can vary from 85% to close to 100%, depending on firing rate and water temperature. However, your system rarely runs at the rating condition, so when the magazine ad says 99% efficient, get online and find the performance curves so you understand how the unit will perform over its expected operating range.

Full Load Performance Factors

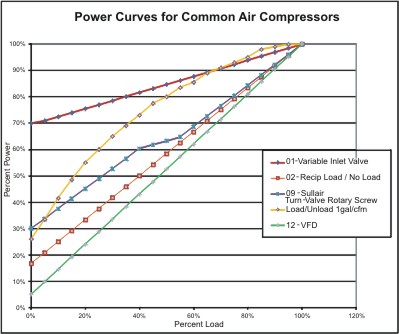

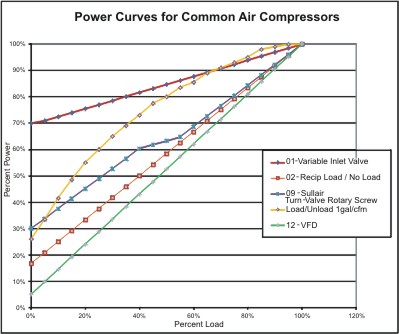

With air compressors, the part load efficiency depends on the unloading method. Inlet-valve-modulation controlled air compressors can use 70 percent of their full load power while idling, and not generating any useful compressed air! On the other hand, variable speed air compressors unload almost linearly, using the nearly the same ratio of power to output up and down the loading curve. See the chart for examples. In any case, air compressors are most efficient when fully loaded. This also holds true for refrigeration compressors, assuming constant temperatures (more to come on this below).

Part Load Performance Factors

Electric motors operate at maximum efficiency at around 75 to 80 percent of their rated horsepower. The efficiency drops slightly when over 80 percent load and drops significantly when operating below 50 percent load. This is more pronounced with smaller motors. Therefore, motors are generally designed to operate between 50 and 100 percent of their rated load. The key here is to ensure that you are not using grossly oversized motors, which can also cause other significant problems like poor power factor.

Water-cooled chiller efficiency typically trends similar to electric motors with a maximum efficiency peaking in the 60-70 percent load range and dropping at lower loads. Air-cooled chillers tend to increase in efficiency with decreased load. You might be thinking, “Wait a minute, above you just said compressors are most efficient at full load.” That is correct, but cooling systems can typically take advantage of the colder heat sink and lower temperature differences (ambient air) to move heat more efficiently. This means as the outdoor air gets colder, the cooling system efficiency goes up. So there are two things going on here.

The load on the cooling equipment decreases as the outdoor air gets cooler, which decreases efficiency. The cooler outdoor air also provides a cooler heat sink for the cooling equipment, which increases efficiency. In most cases, the second effect prevails.

In the End

When choosing equipment based on efficiency, it is important to know how it will be operating, full load or part load, and how long at the various loadings. This includes the entire chilled water, boiler, compressed air, refrigeration, or other plant equipment, which should always be considered at retrofit time. Using this information and the part load equipment efficiencies will allow you to make an informed decision about purchasing efficient equipment.