Humidity control is like negotiating a snow drift on the road; avoid it when you can and when you can’t, take it with gusto or you’ll be beached waiting for the tow truck.

Moisture Source

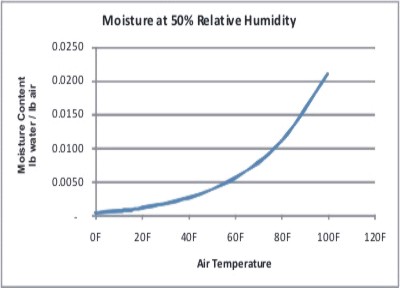

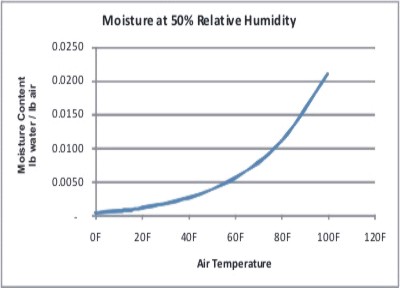

For many cases when humidity control is a problem, the primary source of moisture is outside air. The chart shows how much moisture air carries at varying temperatures with a relative humidity of 50% Clearly, warm air can carry a lot more moisture. 100F air can carry about twice the moisture of 80F air, and 80F air can carry about twice the moisture of 60F air.

Moisture Removal

In most cases, moisture is removed by cooling air to the desired dew point*, which is typically 50F to 55F. This condenses water onto the cooling coil where it makes its way down the drain. Doing this effectively is the key to controlling indoor humidity. What does this mean? Next section, please.

Two Scenarios

Scenario #1: Outside air flow for ventilation is maintained at full occupancy levels during warm summer months while most spaces are unoccupied. The outside air is flooding the building with moisture faster than the cooling coil is removing it. Why? Because the cooling coil is controlled to maintain space temperature (usually) and not relative humidity. The cooling coil may need to produce 65F air to maintain temperature set points and this is not dry enough – refer to the chart above. If the space were really occupied, people, lights and equipment would be producing enough heat to require 55F air, which is dry enough.

Solution #1: Avoid the source when you can. If you have no need for outside air, shut it down. In addition to fixing the humidity problem, it also reduces cooling energy because outdoor air is warmer and carries more moisture, both of which add to cooling load.

Scenario #2: Outside air is shut down while exhaust fans are spinning away. This occurs in both commercial and industrial facilities. Outside air comes from air handling units so shutting that source down takes care of the problem, right? Not if significant volumes of exhaust are required for processes, bathrooms, or kitchens. The air being exhausted is made up one-for-one by leakage through every crack and opening in the building. This unconditioned air mixes with building air and may cause process problems, comfort problems, and may actually require more energy consumption. When you can’t pull the doors open or you nearly get blown off your feet while entering or leaving the building, you know what is happening.

Solution #2: Deal with it. Condition outside air to desired moisture levels when you need outside air! If you have a new construction project, consider a dedicated outside air system to minimize dehumidification energy consumption. In addition to fixing the humidity problem, comfort and manufacturing processes improve. Energy consumption may also decrease if less efficient means of dehumidification (e.g. grocery store refrigeration) are used, whether intended or not.

Remember the Drift

Just as you would with the snow drift, choose to avoid the problem or face it head on. If you don’t need outside air, avoid it! When you need outside air, condition it – and laugh in the face of the almighty snow drift as you pass through with ease. But keep your shovel just in case.

For more on saving energy while dehumidifying please see my article in ES Magazine.