About two years ago, I wrote Duct Leakage Chaff, which explained that residential duct leakage is a mole hill, a red herring, a boogeyman. I recently reviewed a report[1] that nails my assertions from June 2013.

The program evaluation (residential HVAC tune-up) was thorough, likely expensive, but worthwhile. Too often, not just in evaluation, but any professional service industry, contracts go to the low-ball bidder. The low-ball bidder either uses the tactic because it’s the only weapon they have, they don’t understand the challenge of doing a decent job (ignorance), or providing actionable value simply isn’t that important to them.

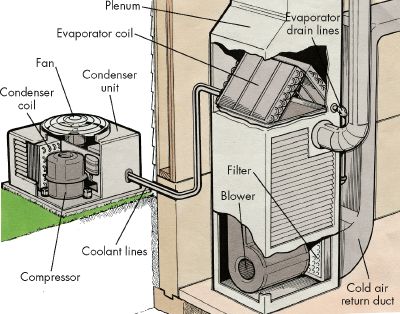

The tune-up evaluation was excellent because it minced up the elements of the program to see what was saving energy and what was not. Three elements of the program were examined as follows:

- Condenser coil cleaning and air filter replacement

- Duct sealing and repair

- Evaporator coil and fan wheel (blower) cleaning

The diagram next door shows all the components very nicely.

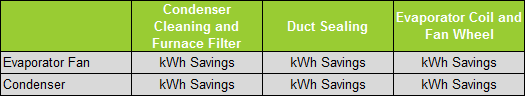

The evaluators collected data for a couple weeks after each step of the measures listed above. Creatively thinking, they reversed the order for about half the samples. In addition, they metered both the condenser and the evaporator blower separately. It was enough to make an energy geek like me tear up. Beautiful.

To digest these words, the table is provided to visualize the elements and how results were broken down. Since the order of measures was reversed for roughly half the sample, there are actually two of these tables.

Evaporator Fan

I would expect anything that increases evaporator air flow to the home would increase fan/blower power. Clean filters result in more air flow and more fan power. Sealing ducts adds flow resistance because after sealing ducts, air must be pushed further through confined channels (ducts). Cleaning the evaporator coil, like replacing the air filter, would increase air flow and fan power.

These realities of physics were mostly proven by the data. The main surprise was that for the part of the sample which had completed evaporator coil and fan wheel cleaning last, savings were shown for the evaporator fan. However, “savings” are in kWh, not kW. The fan may draw more power with a clean wheel and evaporator coil, but cooling capacity would increase much more such that the run time is lower, resulting in energy savings (one theory).

Condensing Unit

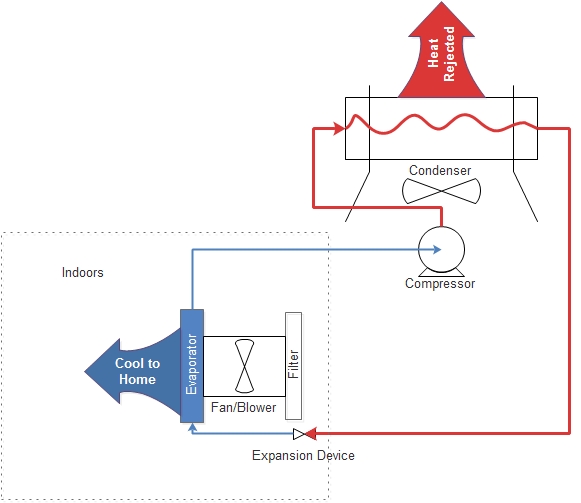

Expect anything that reduces compressor head pressure to reduce condensing unit capacity[2]. To explain this, let’s view/review the simple refrigeration cycle used for cooling, shown below. Refrigerants, like water, boil or “evaporate” at one temperature for a given pressure. For example, water boils on your stove at 212 degrees (212F), or slightly lower at high altitude where atmospheric pressure is lower. In a perfect vacuum, it boils at almost 32F. This is how it can be used as a refrigerant – it boils at low temperatures when pressure is decreased. Conversely, to generate high steam temperatures, we constrain the pressure and it boils at very high temperatures.

Condensing Unit

The same thing happens with common refrigerants in your refrigerators, freezers, and air conditioners. The refrigeration / condensing unit compressor takes care of the pressure change that makes air conditioning and refrigeration possible.

What I didn’t mention yet is when the phase changes from liquid to vapor, it absorbs a lot of heat (boiling water on your stovetop). When the phase changes from hot vapor to liquid, it rejects a lot of heat. The absorption of heat occurs indoors and the rejection happens outdoors for an air conditioner.

Anything that impedes heat transfer to or from either coil increases the head pressure of the compressor. The compressor compresses gaseous refrigerants from 50F at roughly twice your car-tire pressure to 200F at nine times your car-tire pressure. The compressor consumes most of the power to cool a home, and therefore, we want to keep coils clean and head pressure low.

Here is a pretty good video in case you want/need more on simple air conditioning.

If the condenser or evaporator coils are dirty or plugged, they are essentially insulated and the compressor pressure required increases, and the capacity of cooling decreases. This requires more run time.

Dirty coils also impede air flow which reduces heat transfer and increases head pressure resulting in the same capacity issues.

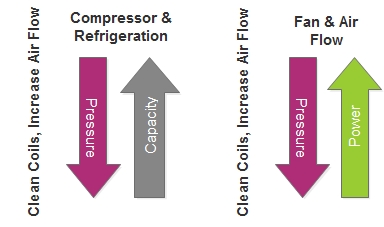

Summarized pictorially to the left.

Cleaning coils increases refrigeration capacity (cooling) but also increases fan power. Fan power increases because air flow (mass flow) increases. The net is lower overall energy consumption. This is what the evaluation data show.

Concluding with the duct leakage repair, I noted above in the Evaporator section that sealing ducts decreases evaporator fan flow and power. This too is what the data show. But, also as explained above, it decreases cooling capacity. Voila, touché, and I rest my case.

This applies in homes where ducts are in conditioned spaces or insulated walls. Where ductwork is full of holes and leaks outdoors or in attics or crawl spaces, there is obviously waste. This is one of two reasons; the other being very high cost to do it right; to avoid design with ductwork outside the shell of the conditioned space.

[1] Not yet published.

[2] Btu/hour or tons cooling