Energy savings calculated from industrial production improvements can be very large. These production changes can be made for multiple reasons, including increasing production capacity, mitigating bottlenecks, reducing waste or scrap, reduced maintenance, or regulatory compliance – as well as energy savings. Specific measurement and verification (M&V) processes were developed into a guidance document called International Performance Measurement and Verification Protocol (IPMVP), as described at the Berkeley Lab website.

Energy savings can be calculated, measured, and verified very differently, depending on the complexity of the project, the magnitude of savings, and the need for rigor in the determination of savings. IPMVP is approached along these lines (see table to the left) –

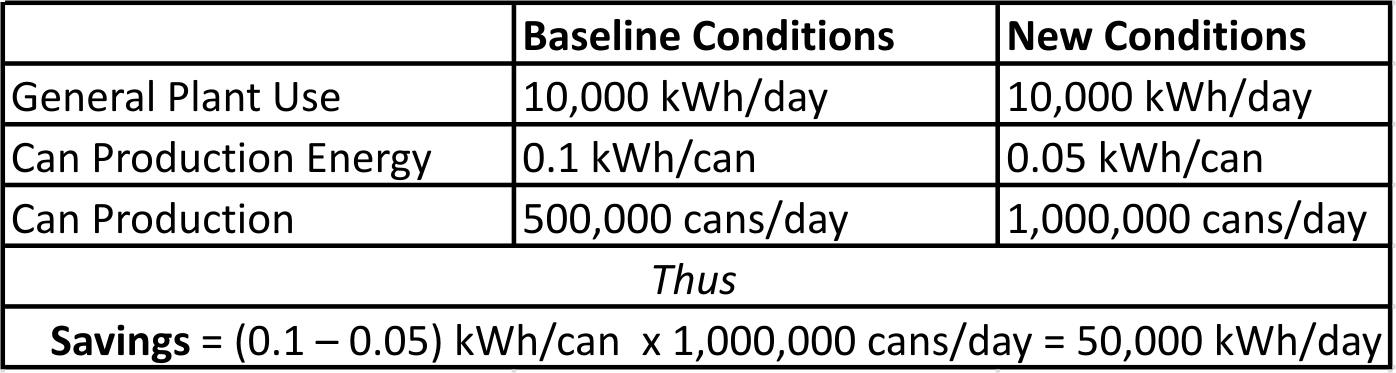

A common approach to the custom production savings calculation is the energy per unit (EUI) for the baseline situation compared to the improved EUI at the new production level (Retrofit Isolation Engineering Model above). The savings are calculated as the difference in EUI (baseline – new) times the appropriate production level. For example, an aluminum can manufacturing plant (see table to the left) –

Baseline determinations are a key part of the savings calculations. The baseline may be different for the “old” process and for the “low efficiency option” for the new conditions, and may provide different results than the calculation above. Program engineers and evaluators must consider many specifics of the replacement situation and may adjust the baseline according to the regulatory rules in use.