The Entire Picture

Energy efficient lighting retrofit projects typically need dollar savings to justify them. Energy dollar savings are obviously the primary driver of these projects, but what about other savings?

Other savings may exist, such as increased productivity due to better light quality, secondary energy savings due to reduced HVAC loads, and maintenance savings for lamps and ballasts. The following is a quick analysis of maintenance cost savings for a lighting retrofit project.

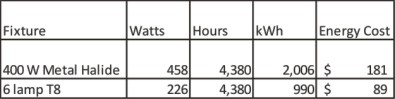

Energy Costs

This analysis compares the energy and maintenance costs associated with a 400 Watt metal halide lighting fixture and a six lamp T8 lighting fixture with high output ballasts. These two fixtures provide nearly the same average light output.

The 400 Watt metal halide fixture consumes 458 Watts, including ballast losses. The six lamp T8 with high ballast factor consumes 226 Watts. Using a 12-hour per day operating period, and an average utility cost of $0.09 per kWh, the total energy cost of energy for each fixture can be seen in Table 1.

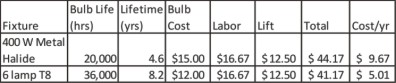

Maintenance Costs

Because the lamps and ballasts for each of these fixtures have different costs and lifetimes, there may be additional savings to be quantified. Metal halide lamps have a rated lifetime of 20,000 hours. Lamps cost approximately $15 each. T8 lamps can have rated lifetimes of 36,000 hours, at a cost of $2 each. Labor is estimated at $50/hr, and three fixtures can be changed per hour. Lift rental is $300 per day since these are high bay fixtures1. Table 2 shows the bulb maintenance costs for this example.

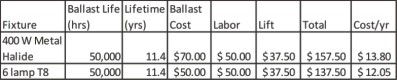

The same analysis with ballasts can also be done. Both metal halide and fluorescent ballasts are rated at 50,000 hours2. The 400 Watt metal halide ballast costs $70, while the T8 fixture uses two 3-lamp ballasts, at $25 each. Ballast labor is for one hour per fixture.

Wrap Up

By replacing a single 400 Watt metal halide fixture with a six lamp T8 fixture, this example shows an energy savings of $91 per year. The annualized maintenance savings for the same project equates to about $6.50 per year. This is about 7% of the energy savings. This will vary project by project, but remains large enough to consider when making a business case for lighting upgrade projects.

1. Labor Rates are estimated using RSMeans. Lamp and ballast costs are taken from reputable online vendors.

2. Ballasts are rated for 50,000 hours at 40°C. This lifetime approximately doubles for each 10°C reduction in operating temperature