A few weeks ago, we reviewed electricity storage technologies, barriers, and issues. One storage technology is the lowly lead-acid battery, which forms the backbone of uninterruptible power supplies for data centers. They are inexpensive with readily available materials, are 100% recyclable, and therefore, they get no attention. Why? Elon Musk, the ultimate hype provocateur. What happened to the PowerWall, by the way? Disruption of rational thought? A web search of “annual Powerwall sales” results in nothing but distantly tangential content.

Similarly, the utility industry, our industry, other companies, and people chase the flashy objects (squirrel!) to obtain decarbonization targets. Flash includes solar panels and toxin-packed LI-ion batteries. To be fair, these are simple and easy to understand. One of the many great, overlooked opportunities for decarb is combined heat and power. Combined heat and power, CHP, is not pure zero-carbon like renewables plus storage but:

- Industrial heat will be provided by natural gas for decades to come because generating it with valuable, flexible electricity, is cost-prohibitive.

- On the flip side, natural gas will be used for decades because of the sheer magnitude of thermal energy required, with 87% of inflowing industrial energy from hydrocarbons, nearly all of which is fossil fuel.

- Finally, renewably generated electricity has intermittency and very expensive storage issues.

Available Waste

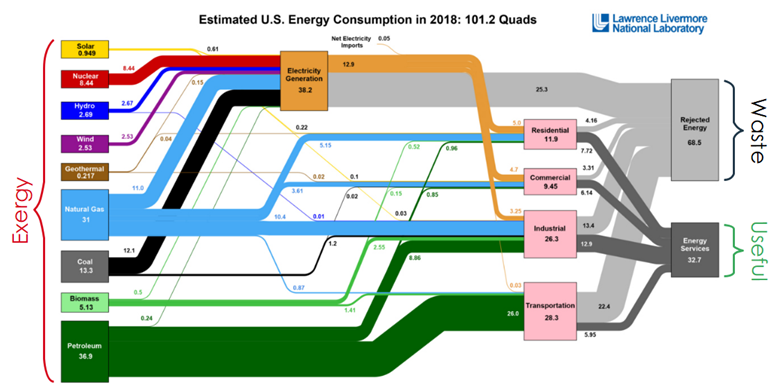

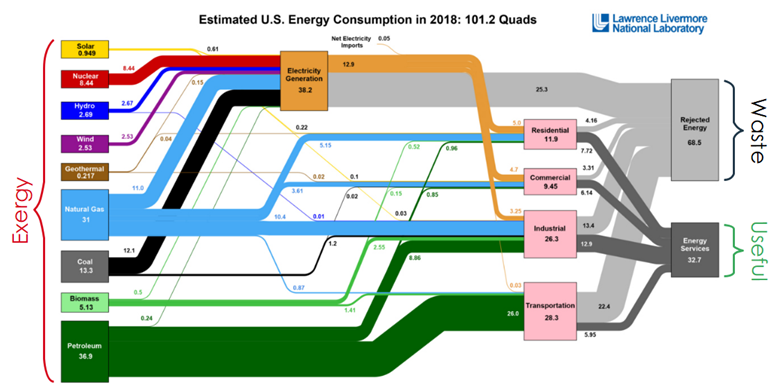

It is a giant mistake to ignore the thermal waste and lost opportunity that could be captured by combined heat and power. Consider the energy flow graph (Sankey Diagram) below from Lawrence Livermore. On the left side, we have sources of energy, which I call exergy. I will come back to exergy below the chart. On the right side, we have useful work, weighing in at a measly 32%, with about 68% being dumped into the environment and never used. Waste!

Now you might be thinking, OMG(!) are engineers that dumb? No. It’s economics. Thermal power plants such as nuclear and coal-fired plants could possibly reach 45% efficiency rather than a typical 33% efficiency.

Now you might be thinking, OMG(!) are engineers that dumb? No. It’s economics. Thermal power plants such as nuclear and coal-fired plants could possibly reach 45% efficiency rather than a typical 33% efficiency.

So let’s do it!

Not so fast. To increase efficiency, the high temperature of the cycle would need to increase substantially. Plentiful and inexpensive steel alloys get wobbly around 1200F. There are also corrosion considerations and other issues. The levelized cost of fuel savings is less than the cost of exotic metals en masse to achieve greater efficiency in a thermal power plant. BUT, there are exceptions I will come back to.

Exergy = Available Energy

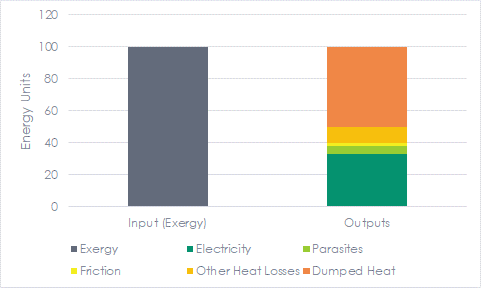

So, what is exergy? Exergy is the available energy in a resource. If we could eliminate power-plant parasitic losses (pumps, fans, etc.), friction losses due to turbulent flow, and particularly avoid dumping about half the heat to the environment, we could capture closer to 100% of the available energy: exergy.

Let’s look at a faux, but realistic example of how exergy in a thermal engine, whether it’s a thermal power plant or your car engine, is wasted. Per the next diagram, the major loss is heat dumped to the environment. Why dink around with the parasites, friction, other heat losses (exhaust and skin losses), solar panels, batteries, and windmills, when we have this huge block of dumped heat that could be used for industrial heat – heat that is otherwise generated by burning more fuel? This is far more brilliant, but not as sexy as PowerWalls, 3s, and solar panels.

Combined Heat and Power

Combined Heat and Power

Using rather than dumping this heat from the power generation cycle is called combined heat and power, and there are many configurations in which to do it. We either need to locate big industrial thermal loads near power plants or put smaller power plants within industrial facilities.

Power-Generating Efficiency

In addition to capturing waste heat, combined heat and power, like combined-cycle natural gas plants, can be twice as efficient generating electricity compared to a nuclear or coal-fired plant. How?

Tons (literally) of exotic metal alloys to increase the efficiency of thermal (steam) power plants is cost-prohibitive. However, a few hundred kilograms deployed in a gas turbine is not. So we get two power cycles with each unit (million Btu, quad, whatever) of energy. We get the Brayton cycle (engine) from the gas turbine, and from the turbine’s hot exhaust, we get the familiar Rankine cycle (steam power plant). Gas-turbine, Brayton-cycle engine performance varies, but assume 35% efficiency, plus another 30% on what’s left for the Rankine cycle, and we have close to 60% efficiency. After that, we still have heat in the form of steam for industrial heating.

Sparse and Weak CHP Penetration

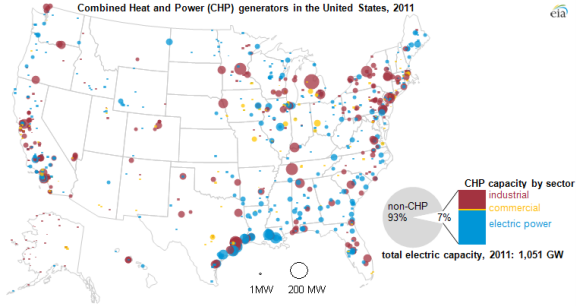

The chart below shows CHP capacity ten years ago, but it is relevant for the purposes of this post. Back then, only 4% of electricity production leveraged CHP. The “electric power” portion is that 4%, and it represents applications where power generation is the primary objective, with steam sold to nearby industrial customers. For example, the blue dot in east-central Iowa represents Alliant Energy’s Prairie Creek station, which generates power while selling steam (waste heat) to International Paper.

What’s the holdup, and what are the barriers? According to Kenneth Costello with Public Utilities Fortnightly, the barriers are primarily policy, aka, political:

What’s the holdup, and what are the barriers? According to Kenneth Costello with Public Utilities Fortnightly, the barriers are primarily policy, aka, political:

- State policies favor renewable resources over CHP. What? I’d also say that replacing apple orchards with seas of solar panels is not sustainable and certainly not visually attractive (Minnesota). Not so with CHP.

- Electric utilities erect obstacles to CHP (per Ken, remember). After all, he writes, CHP is a distributed resource that competes with electric utility sales.

- Industrial energy users with favorable CHP opportunities find ROI on CHP (5-7 year payback) not to be attractive compared to other investments.

- His fourth and final barrier is a group of tactics supporting the second bullet above: high standby rates, clunky interconnection rules, etc.

Three-Legged Stool of Decarbonization

The three legs of decarbonization are clean, reliable, and inexpensive. Any two are easy, but the third takes a lot of balance, and that’s what you’ll get at my headliner course at AESP’s Spring Training. We will cover combined heat and power, energy storage, electrification, transmission, policy, and more. The objective is to learn and know what you don’t know today.

Combined Heat and Power

Combined Heat and Power