Bulk Transport Systems

Also known as pneumatic-conveying, these systems use air compressors, blowers, or fans to move things from flour to everyone’s favorite frosted, sugar-packed cereal throughout facilities. There are two main types of bulk transport systems used:

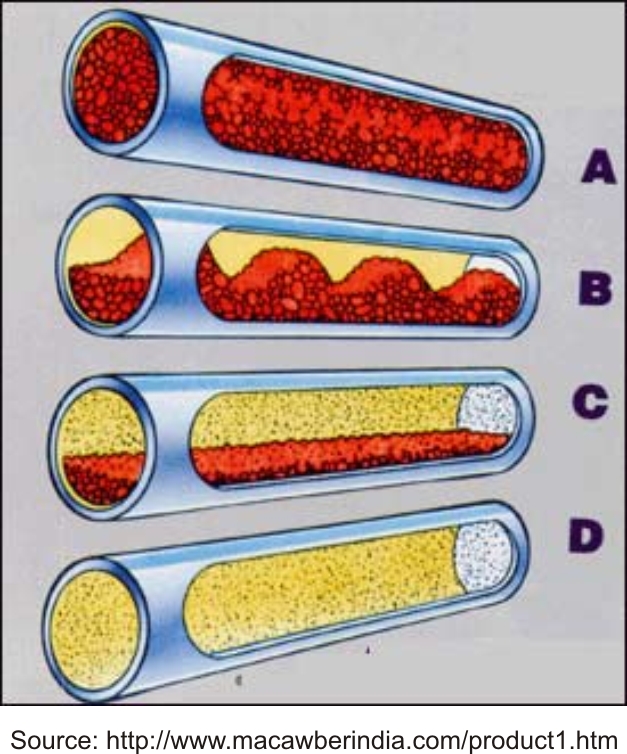

Dilute phase: utilizes low-pressure air to move product suspended in the air stream at high velocities – think of flour flying through a vacuum cleaner hose to its canister/bag, as demonstrated in the image below, case D.

Dense Phase: utilizes high-pressure air to move product that is not suspended in the air stream at lower velocities – think of slugs or a continuous flow of product, like cereal, as shown in A-C below.

Dilute phase transport is usually used for nonabrasive, non-crushable materials due to the high velocities. Dense phase transport is used for products that can be damaged or crushed.

Dilute Phase: Bigger Fans = Better System Operation and Flow…. Right?

Wrong! This is a common misconception. Increased flow in dilute phases does not mean more efficient product transportation. In fact, it often means the opposite as it can lead to increased pipe wear, damaged product, and high blower energy use due to the very high mass flow of air relative to the flow of product.

Properly designed dilute phase systems should be operated to maintain the material’s minimum conveying velocity — or the velocity required to keep the material suspended in the air stream. Systems operating at this velocity will minimize fan energy costs while decreasing maintenance and material damage.

If settling problems occur in an existing system, a leak analysis should be considered before increasing air flow. Leaks will reduce the transport velocity, which can cause settling problems as particles (product) begin to fall out of the air stream.

Dense Phase: Just Add Compressed Air?

Wrong! Depending on the material, travel distance, and capacity needed, there are many methods of dense phase transport. These range from fluidized dense flow (C in the image above) to multiple dense material slugs (B in the image above) in the system. If an inappropriate dense phase transport type is used, the system can experience pipeline blockages and excessive pressure spikes.

While dilute phase transport systems require constant flow, dense phase transport systems typically operate with the intermittent flow of compressed air. Energy savings can be achieved by implementing an airflow control system. A properly operating control system will minimize and cycle compressed air flow, reducing air compressor energy use.

What does it all mean?

In general, bulk transport systems are designed based on specific velocity, pressure, material type, material ruggedness, and capacity requirements. Due to the complexity of the system, it is recommended that the process be reviewed to fully realize the energy saving potential.

Sources:

- Pneumatic Conveying Systems, A. Bhatia, CED Engineering