That Old Boiler May Not be That Bad…

Old boilers are often mistakenly assumed to be inefficient; 75% efficient, 70% efficient, 60% efficient. We have even seen claimed efficiencies as low as 50%! The facts are that a vast majority of boilers, regardless of age, test 80% or better on combustion efficiency! Even some ancient coal boilers that were converted to gas decades ago are typically in the 80% efficiency range.

Nearly all operating boilers are designed with sufficient heat transfer area to extract 80% or more of the gas energy burned in the burner. Lack of boiler maintenance such as poor water treatment or neglected burners with inappropriate air/fuel ratios can result in efficiency degradation over its lifetime. However, boilers are rarely neglected such that significant irreversible losses in performance occur.

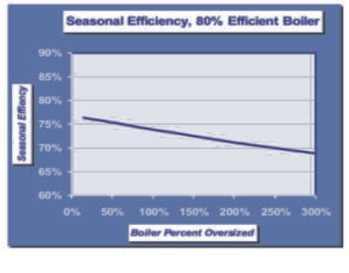

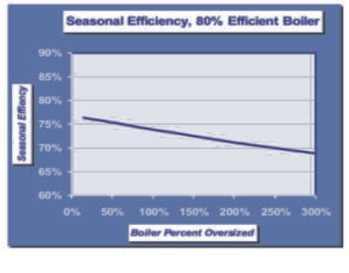

Often times what one does find is that boilers are excessively oversized. Boilers were over-sized in the 1950’s and 1960’s as well as earlier years because equipment was cheap, energy was cheap, buildings were poorly insulated and heating load calculations were imprecise. Excessively oversized boilers will certainly have a negative impact on seasonal efficiency as the chart shows.

Many times it is easy to ascertain whether a boiler matches the heating load of the facility, particularly if annual gas use for a given boiler or heating plant can be determined. For most commercial facilities this is straightforward.

Always insist that a load calculation be performed prior to replacing a boiler. The worst mistake we see is customers replacing an oversized boiler with an identically oversized boiler. The customer pays more for larger equipment and is saddled with the same inherent inefficiencies, and may achieve little if any energy savings.

In addition to always performing a load calculation, consider the following:

- Consider converting steam systems to hot water. Steam systems cost more to maintain and have inherent losses not present in hot water systems. Although energy savings alone will likely not fund the conversion, the life-cycle cost may be lower since hot water systems are much easier to maintain.

- Implement hot water reset control to use the coolest water possible to meet loads. Reset will decrease piping heat losses, improve temperature control, and result in better boiler efficiency. Install condensing boilers that are 90%-plus efficient.

- Look for boilers with a large turn-down ratio (low percent minimum fire).

- Consider modular boiler systems and sequence to operate at their maximum efficiency. For many modern boiler systems, this means operating as many modules as possible at their lowest firing rate.