I have written about, and formally discussed, strategic energy management (SEM) so much I was sure I already wrote a Rant on the topic. After looking, I wrote about SEM and Yoda, Try Not, Do or Do Not, a year ago, but that was about measures and opportunities. This time, let’s consider SEM programs.

SEM Beyond Industrial

Strategic energy management is often pigeon-holed as an industrial or manufacturing effort. This is unfortunate and wrong. Strategic energy management is great for commercial and multi-family facilities.

Strategic energy management is especially good for MUSH (municipalities, universities, schools, and hospitals) but also office buildings, especially large ones and corporate campuses of odd-ball facilities; e.g., financial and insurance sectors.

Strategic energy management is also great for multi-family housing. Four years ago, I wrote a case study regarding a comprehensive multi-family efficiency overhaul in Bling not Required. The developer vastly improved efficiency, guaranteed maximum tenant energy cost, installed new appliances, made lots more money, and the tenants loved it.

SEM Cohorts and Energy Managers

Two common elements of SEM programs include cohorts and embedded energy managers.

Cohorts feature energy management and executive-level representation from six to twelve, or more, organizations participating in SEM. It works a little like Anger Management, with leader Dr. Rydell (Jack Nicholson). Simply swap anger for energy. It’s easy. Goosfraba.

Participants of the anger, er, energy management cohort occasionally meet to discuss their problems and challenges. The cohort leader, Dr. Rydell, provides instruction, fosters engagement and idea sharing, and helps cohort participants help themselves. Hopefully, peacemaking is not required.

For the embedded energy manager option, Dr. Rydell lives with the energy user full-time or part-time. An embedded Dr. Rydell provides an array of services including identifying energy-saving projects, waste reduction possibilities, and evaluating processes for improvement. In the second scene, for instance, Dr. Rydell demonstrates why quality control is critical to reducing waste: two eggs and two pieces of toast in this case.

SEM as a Feeder Program

Strategic energy management should be a feeder program that includes anything and everything that saves energy and improves productivity. Improved productivity almost always means improved efficiency. Projects identified in a SEM program should identify measures and activities beyond behavior and no/low-cost process improvements. These projects feed other programs:

- Prescriptive measures

- More complicated custom measures

- Retro-commissioning

- And especially planning

SEM as a Planning Mechanism

What is planning? Commercial facilities twenty years old or older have equipment rapidly reaching, or already past, useful lifetimes. Industrial and manufacturing facilities are always morphing to alter or change product lines, increase capacity, and many other necessities.

Possibly the best use of SEM, which I rarely, if ever, have read or heard about, is planning energy efficiency into these needed facility changes. Strategic energy management needs to be engrained and embedded into the way of life for an organization. Like any therapy, physical, or otherwise, a lifestyle change is needed for lasting results.

An example includes a facility asset management plan we are working on now for a private college. For this project, we are assessing remaining lifetimes of significant equipment and systems throughout campus and simultaneously planning energy efficiency into required future upgrades.

If you get anything from this edition get this: Blown planning opportunities are probably the greatest untapped and under-tapped potential there is. Why? It takes time; it isn’t instant; it requires expertise. Get with it! Plan ahead!

EIS v EMS

Don’t you love acronyms? They are like diseases; I try to manage them because they are a transmittable bane of life.

An EIS is an energy information system, and an EMS is an energy management system.

Let’s start with the energy management system. Also known as building automation systems, energy management systems are control systems that, at minimum, take inputs by the dozens, and through canned algorithms, send out an equal[1] number of control outputs to the HVAC system. Energy management systems may also control lighting and take inputs from security and fire protection systems.

Despite claims, energy management systems have lousy analytics. They can supply data for analysis, but they paint a poor picture for action.

Energy information systems display key information to manage energy. They are used with regression models (curve fitting) to project energy consumption considering variables like time of day, day of week, weather conditions, production activity, occupancy, and essentially an infinite number of variables. Like any other energy thing, the key is using only the parameters that matter. Complexity and cost build exponentially with the number of parameters.

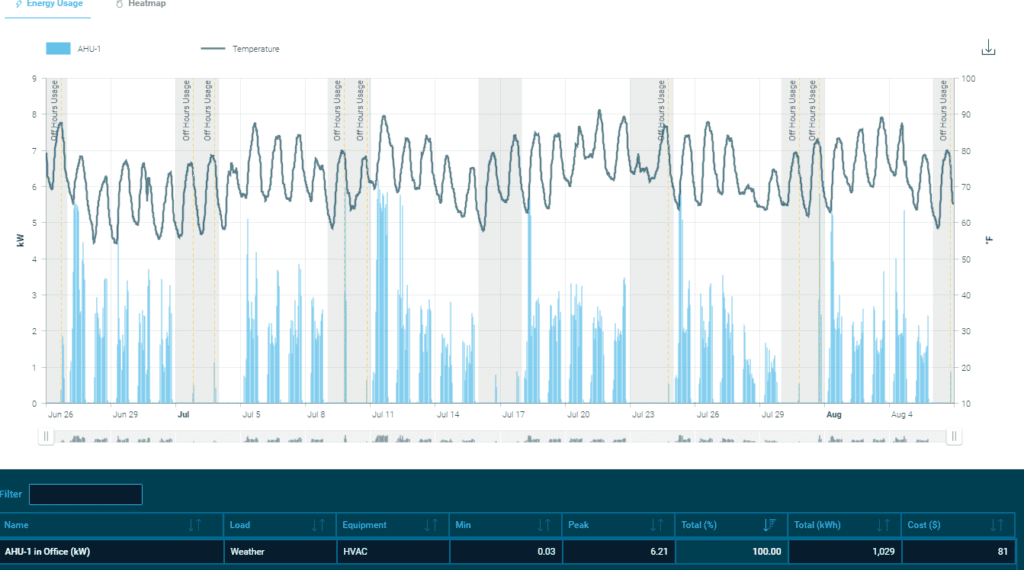

The screenshot below is from a system we tested on our air handling unit. The continuous wavy line is outdoor air temperature, a key parameter, and the bar charts are fan motor power by hour over a period of six weeks. You can see that coming off the weekend, the fan sets a demand spike to pull the temperature down for Monday occupancy. There is example #1 for saving money with an energy information system.

Tune In and Amp Up

To see and hear more from some people who actually know something about SEM, tune into AESP’s online conference Energy Management… Is the Boss. Bryce Dvorak from Michaels leads off with an overview of SEM nationwide.

[1] About