What is it?

Sequencing controls automatically tell a system which piece of equipment to operate and in what order. Typically, this means operating the most efficient piece of equipment based on demand or loading. Such controls can be added to many types of systems with multiple machines. The controls are especially useful when coupled with variable frequency drives (VFD).

Where to Look?

Compressed air systems with multiple compressors are often prime opportunities to consider for sequencing issues. Fixed speed or centrifugal air compressors are best suited for operating as the base-loaded (100% capacity) machine. Operating at 100% capacity is where it is most efficient. If the air demand is significantly less than the capacity of the base load compressor, a variable speed compressor can supply the remaining air demand at a higher efficiency when compared to a fixed speed compressor operating at part-load.

How Does it Work?

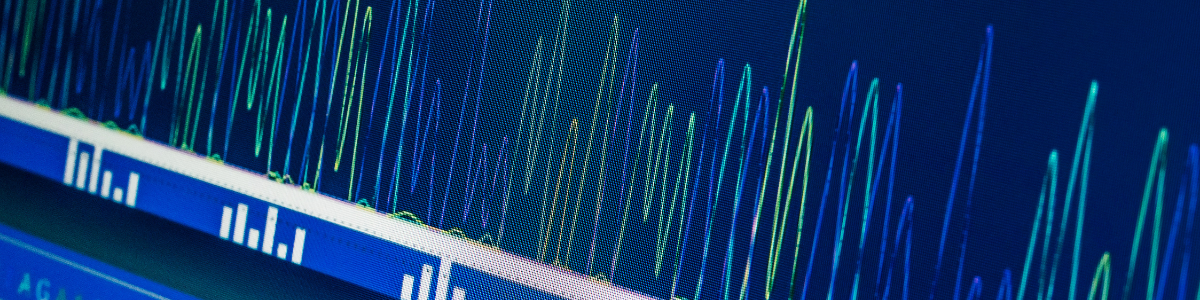

For example, chart 1 (to the left) shows compressed air demand at a facility throughout an average day. Compressed air is provided by a fixed speed air compressor and a VFD air compressor.

If the fixed speed compressor has a capacity of 1,000 CFM, the simple setup is to run the VFD compressor when the air demand rises above that set point. However, fixed speed air compressors require more power than VFD compressors at part-load conditions as shown in chart 2.

Sequencing controls would switch the operation of compressors and let the VFD compressor operate during part-load conditions. In this example, the VFD compressor would turn on when the air demand is 750 CFM or above 1,000 CFM to trim the remaining air demand above the capacity of the fixed speed compressor.

What are the Benefits?

Chart 3 shows the energy usage of the compressed air system when sequencing controls are used and when sequencing controls are not used.

The gray line represents the compressed air system that utilizes sequencing controls. The controls will sequence the fixed speed and VFD air compressors to operate in the correct order based on the required air demand. In this case, the VFD air compressor will operate during periods of low air demand (750 CFM), and operate as the trim, or secondary, compressor during the peak air demand (1,500 CFM). As shown in the graph above, there is significant energy savings potential when operating the most efficient air compressor based system air demand.