Congrats! You flew through Hot Water Reset Controls 101 (which was just six short weeks ago, but if you need a refresher, you can find one here). Now it’s time to move beyond the concepts from 101 and focus on key details facility owners need to consider to optimize performance of new controls. These finer points will help guide the successful implementation of hot water reset controls.

Have a Condensing Boiler

While turning down the water temperature is great, the efficiency improvement is minimal, only saving shell losses in a traditional boiler.

This is one of the most common misconceptions with hot water reset controls. Turning down the water temperature supplied by a boiler will improve the efficiency, but the savings are essentially limited to reducing the shell losses because the boiler won’t run as hot. Shell losses often account for less than 2% of the boiler consumption.

Condensing boilers can supply cooler water while utilizing some additional heat recovery. This greatly improves the efficiency when operating at lower temperatures. However, there is another aspect of condensing boilers that must be addressed.

Properly Control Return Water Temperature

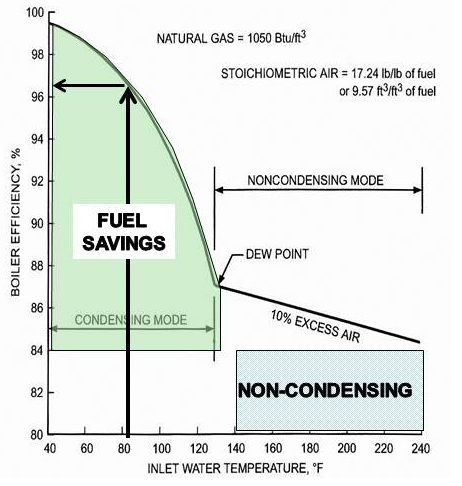

Without properly controlling the water entering the condensing boiler, it essentially operates like a standard non-condensing boiler. As can be seen in the figure to the right, if the water entering the boiler isn’t cool enough, the condensing feature won’t work. No condensing equals no additional savings for the boiler, which means tiny additional savings for hot water reset controls. Therefore, make sure the inlet water temperature is controlled to a fixed point that is as low as possible to maximize operation.

Adequate Coil Size

One of the qualifying statements made in Hot Water Reset Controls 101 was that the heating coils need to be properly sized. If the hot water coils are too small, there won’t be enough heat transfer to the air stream to heat up the space properly. This will cause the system to stay in heating mode longer than would otherwise be needed.

Put VFDs on Hot Water Pumps

Finally, adding variable frequency drives (VFDs) to the hot water circulation pumps can further improve the overall efficiency of the system. While not as significant as the other items described previously, saving on pumping energy can be significant if the system is large enough.