Plastic, Plastic, Everywhere

Take a look at an office desk. There are a variety of items that were created using an injection molding process; from the keys on a keyboard, the cover on a phone, to the plastic bin that keeps pens separate from paper clips. All of these plastic parts were manufactured somewhere by something; typically an injection molder.

Making the Part

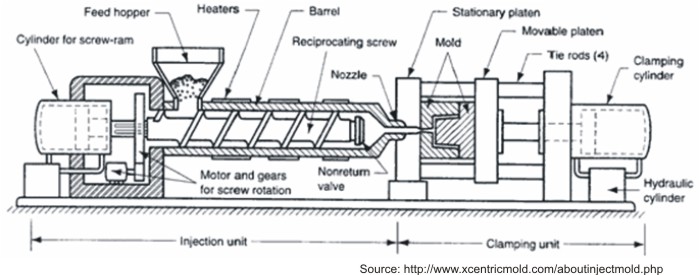

A basic injection molding machine consists of a hopper connected to a screw contained in a barrel. At the end of the barrel is a clamp holding a mold for the part that will be produced. The plastic material is introduced through the hopper as pellets, which move down the screw where they are melted through frictional forces and electric heaters around the screw barrel. The injection molding process takes place as follows: the mold closes, the screw turns and injects the melted plastic into the mold, the mold and screw hold pressure while the material cools, and the mold de-clamps, opens, and ejects the part.

Hydraulic versus Electric

Before the mid-eighties, injection molding machines used hydraulics. Not until the last 15 years or so have all-electric injection molders become more common. With hydraulic machines, the system must maintain hydraulic pressure for mold clampinig at all times, meaning a high idle energy usage. Also, hydraulic oil requires constant cooling and can create maintenance challenges through leaks, especially with older machines. The advantage of electric machines is that they use servo motors that have much more precise controls and only use energy when they are needed (no high idle energy use). As the technology has progressed, the all-electric machines have higher repeatability, better precision, and faster cycle times than hydraulic in many cases.

Energy Savings

The advantages of all-electric injection molding machines can be enormous when it comes to energy savings. The reduced idle time energy usage and reduced cooling costs can produce energy savings over 60% when compared to hydraulic machines, which has been proven in many projects backed by metered data. Additional benefits include reduced labor costs, increased production, and possible utility incentives for reducing energy usage. The energy savings, however substantial, will likely not pay for a new all-electric injection molder by themselves. But, when an old machine has to be replaced, or when comparing the incremental cost between new hydraulic and electric machines, the savings available from all-electric can make the added cost well worth it.