Back pressure turbines are not new technology but their popularity is increasing with ever rising electricity and demand rates. By installing back pressure turbines on a high pressure steam system, recent jumps in electric utility costs can be offset with power produced on site. A back pressure turbine is simply a steam turbine used to generate electricity with relatively small decreases in steam pressure.

Crank Up the Pressure

At high pressure, steam can operate a turbine generator such as in a power plant when steam is in excess of 1,500 psi. On a smaller scale, gas fired steam boilers can also operate at increased pressures to produce steam to be converted to electricity by a back pressure turbine. Additionally, back pressure turbines can be used in lieu of throttling valves to convert relatively inexpensive steam into more valuable electricity.

Backpressure turbines should only be considered when a boiler has steam flows greater than 3,000 lbs/hr and when the steam pressure drop is at least 100 psi. Since turbine exhaust steam will have a lower temperature and enthalpy, the boiler steam energy input/output is usually increased by 5%-7% to make up for steam energy converted to electricity. Every Btu of heat that is converted to electricity is made up with an equivalent amount of heat at the boiler to maintain steam energy for downstream processes.

Power

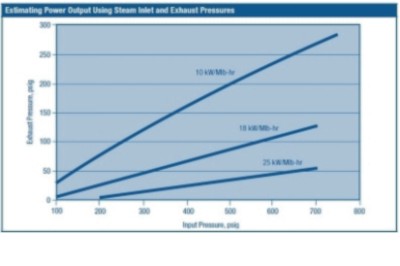

The potential power output by the turbine generator is calculated by comparing the inlet and exhaust pressures at the turbine. Depending on pressure differentials, anywhere from 10 to 25 kW per thousand pounds per hour (Mlb-hr) of steam can be produced.

In cases where steam is purchased from a district steam system, a back pressure turbine can be installed instead of the usual pressure-reducing valve if delivered steam pressures are high enough.

Costs for back pressure turbine generators complete with electrical switchgear range from $900 per kW for a small system (150 kW) to around $200 per kW for large units (2,000+ kW). Installation costs typically average 75% of equipment costs.

What About Green Power?

Some customers contemplate installing PV solar panels or wind mills to create their own power. In a comparison, renewable technologies don’t even come close to CHP in many applications. A back pressure turbine doesn’t need to be located on a windswept plain or a sunny rooftop in the desert to become feasible; it will work wherever a steam system is being used. It has nothing to do with being green and everything to do with taking advantage of wasted opportunity. A back pressure turbine will work 24/7 with a constant energy output, thus making this technology ideal for many industrial and large commercial facilities.