The Rankine Power Cycle

Water is the working fluid for all coal-fired and nuclear power plants in the U.S., and the world for that matter. In the U.S., it produces about 70% of our electricity. Water is boiled to make steam at high pressure which is then used to expand through a turbine to generate electricity. This cycle is known as the Rankine cycle, named for the engineer who developed it in the 1800s.

Opportunity

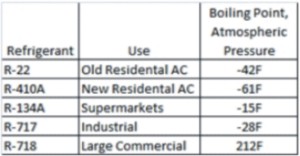

Did you know water can also be used as a refrigerant? Actually water, also known as R-718 (R for refrigerant) is used as refrigerant in absorption chillers that are not all that uncommon. Since water can be used as a refrigerant for space cooling, or working fluid in power plants, why not use refrigerants for working fluids in a power generation cycle? This presents a great opportunity to generate electricity using relatively low temperature waste heat.

There exists about one refrigerant for every day of the year. The table shows some of the more common ones along with their boiling points at standard atmospheric pressure.

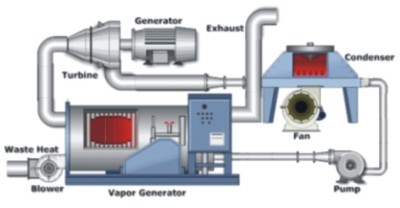

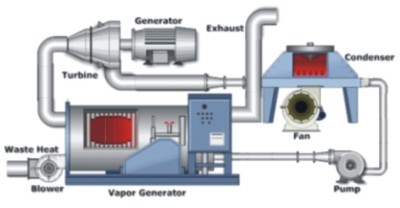

Most refrigerants boil at a much lower temperature compared to water for a given pressure. Therefore, refrigerants are suitable for use in Rankine cycles using refrigerants as working fluids. Most of these refrigerants include a mess of carbon, hydrogen, and fluorine and thus the HFC (hydrofluorecarbon) and HCFC, CFC, etc.. These are called organic compounds and hence the term organic Rankine cycle heat recovery and power generation. The system and cycle is depicted in the diagram.

Drawbacks

Most conventional refrigerants fair poorly in an organic Rankine cycle because they can only be used at low peak temperatures. Power plant efficiency increases with higher steam temperatures and pressures. The reason steam power plants are stuck in the 30-40% efficiency range is that steel gets wobbly at higher temperatures of about 1200F. These conventional refrigerants are only good in the 200-300F range and therefore have very poor efficiencies in the 5-10% range. But hey, the “fuel” is free so it may still be cost effective.

Hurdling the Barriers

Not being satisfied with using off-the-shelf refrigerants, entrepreneurs experimented with mixtures of refrigerants. Refrigerants are a bit like bread-baking with different types of flour. Many are just concoctions of other refrigerants. The result has been organic Rankine cycles that can operate above 800F with a dramatic increase in cycle efficiency to about 25%. I’ve seen a lot of metal processing (annealing), steel, and glass-making plants exhausting these kinds of temperatures.

That’s not all. You can still recover a lot of heat for processes, preheating air, or water once the waste heat runs through this cycle.

If you have a lot of waste heat1 close to 24/365, you should consider the organic Rankine cycle plant to make valuable electricity.

1Examples of minimum waste heat needed: 750 cfm @ 900F or 4,000 cfm @ 300F. These temperatures bracket the range of temperatures of waste heat that can be used for generation.