What is Benchmarking?

Energy benchmarking is the process of determining how much energy your facility uses relative to another standard. Energy usage can be compared to past facility usage, industry averages, industry best in class, or best practices. The facility in question can then be ranked to determine if it is energy efficient.

Where to Obtain Benchmarking Data

There are several sources that have readily available benchmarking data. One such source is ENERGY STAR. ENERGY STAR offers a portfolio manager that allows you to enter your facility’s electric, natural gas, and water usage along with building characteristics. After the data are entered, a score is given to your building. A score of 70% indicates that 30% of similar buildings are less energy intensive and 70% are more energy intensive than yours. The portfolio manager is available here.

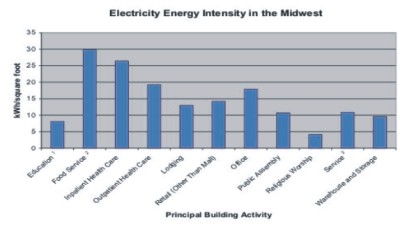

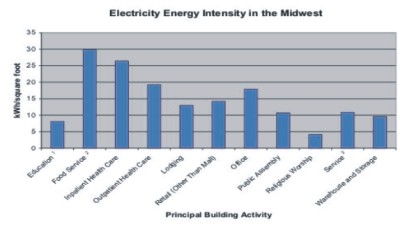

Another source of data for benchmarking is the Commercial Buildings Energy Consumption Survey (CBECS). This is a survey conducted by the Energy Information Administration. Energy consumption data for various types of commercial buildings are available and sorted by several characteristics such as building size, climate, and year of construction. This data is available from the U.S. Energy Information Administration. The chart shows average energy intensity of various building commercial types in the Midwest.

Why Should I Benchmark?

Benchmarking can be a useful tool for determining whether your facility could use any energy efficiency improvements.

If your facility uses more energy than the average building (~50% ENERGY STAR rating), there may be some substantial improvements that can be made to your facility. If your facility uses less energy per square foot than the average building of similar end use (>75% ENERGY STAR rating) your building may be efficient, but you need to be sure you meet ventilation requirements as well.

Benchmarking can also be used to track the facility’s energy usage over time. If you submeter energy for specific items at your facility, you have even more useful data available. For instance, if a spike in energy consumption during a day is noticed, the source of the increase can be more easily tracked down. Without actively tracking your energy consumption a piece of equipment that becomes faulty and inefficient may not be promptly noticed.

How to Benchmark

First, the scope of what you want to benchmark should be determined. This can be as simple as benchmarking a single piece of equipment, or as complex as benchmarking the entire facility or campus.

One thing to keep in mind is that an apples to apples comparison is necessary. Comparing energy consumption of one building directly to energy consumption of another building is not necessarily telling. Usually energy consumption normalized by the square footage of the facility (energy intensity) is used. For manufacturing processes, the energy consumption is generally normalized by production. For weather dependent systems and processes, energy consumption should also be normalized by the weather data (heating or cooling degree days).

Energy benchmarking is one of the first steps in establishing a successful energy efficiency plan for your facility. The data provide an easily quantifiable gauge for the performance of your facility so you can direct your efforts to a cost and time efficient energy management plan.