Ultraviolet (UV) Not Just for Sunburns

Ultraviolet light is produced by that glowing ball of gas in the sky, the Sun. This should be especially familiar to anyone who has spent more than an hour outside on a sunny July day or more than a minute outside in the sunburn capital of the U.S., Florida. Ultraviolet light can do more than just damage skin cells. It has applications in printing, wastewater treatment, and sterilization, to name a few.

It would not be wise, however, to rely on the Sun to operate your printing process, so UV processes generate their light using electric light sources. This is most commonly done with mercury vapor lamps.

What’s wrong with mercury vapor?

Generating UV light using mercury vapor lamps and fixtures is less than ideal. Mercury vapor lighting is a type of high-intensity discharge lighting that uses gaseous-mercury-filled tubes and small electrically-charged filaments to produce light that is very bright and blue or violet in color. In addition to all that visible light, mercury vapor lamps produce large amounts of invisible UV light.

Mercury vapor lamps have a number of drawbacks:

- They send light in all directions, even if it is only needed in a specific area.

- They generate light in many different wavelengths, which are unnecessary.

- They generate large amounts of waste heat.

- They require dedicated exhaust systems to remove harmful vapors (ozone).

- They are an inefficient light source in terms of UV light output per watt.

- They burn out frequently and degrade over time (24,000 hour life time is typical).

What’s the alternative?

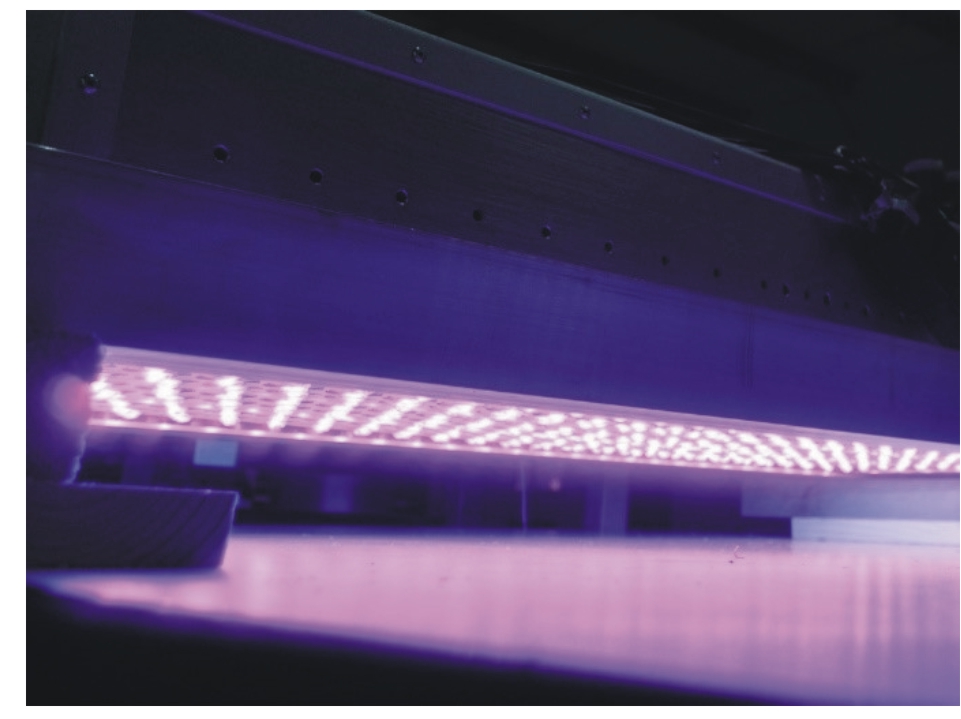

Fortunately, there are better options for generating UV light. Many manufacturers offer LED UV lighting. LED fixtures address all of the issues of their mercury vapor counterparts:

- They can be made to focus light only where it is needed and nowhere else, while only producing specific wavelengths of UV matched to the application.

- They produce less waste heat.

- There are no harmful vapors, like ozone, to remove with an exhaust system.

- They have a very high UV light output per watt rating.

- They last two-to-three times longer than mercury vapor lamps with little degradation in light output over time.

LED UV and Not MV UV (Acronyms Galore!)

Although LED UV lamps are more expensive than mercury vapor options, in most cases, they more than make up for the difference in terms of energy, maintenance, process control, and throughput (LEDs start up instantly with no warm up or cool down time like mercury vapor). In dry offset printing, special ink is required for LED lighting. This ink costs more than the standard ink for mercury vapor lighting, so LEDs are not cost effective in that application right now.

However, in wastewater treatment, sterilization, screen or ink jet printing, and other areas where the only added costs are for the LED fixtures themselves, they are a wise choice over mercury vapor fixtures. There’s no reason to be burned by your facility’s UV lighting by sticking with mercury vapor.