Yes, in my back yard! There is a new model catching momentum in the energy business. Combined heat and power (CHP) systems show promise for distributed generation, efficient electricity generation, and pollution reductions. CHP systems are systems that provide both electricity and heat to a facility. This brief covers two types of CHP: Generation Heat Recovery and Back Pressure Turbines.

In generation heat recovery systems, electricity is generated with a natural-gas-fired turbine or an internal combustion (IC) engine, and the waste heat is used to generate steam or hot water before exhaust gases are discharged. In the case of a back pressure turbine, heat is the primary objective, while the turbine extracts energy to produce electricity as the steam pressure is reduced. In either case, highly valued electricity is generated at very low cost, where natural gas consumption is required anyway.

Systems using IC engines are typically somewhat less expensive than those that use gas turbines. However, the drawback of IC engines is that they reject heat at relatively low temperature and therefore are not suitable for steam generation. Gas turbines, which are essentially jet engines with a generator added, produce waste heat that is easily of a high enough temperature to make steam.

Back pressure turbines can take the place of pressure reducing valves that essentially waste potential energy of high pressure steam. With back pressure turbines, relatively inexpensive thermal Btus are transformed into highly-valued electrical Btus with very little loss in net energy.

Applications

Year-round simultaneous electricity and heating demand is the most important factor in determining if CHP systems are right for a given application. The capacity of the system should be small enough such that it can run nearly fully loaded at all times. Hospitals, supermarkets, food processing plants, and other industrial plants can all be good candidates for CHP systems. Generally, any facility with substantial thermal loads, both heating and cooling, is a good candidate.

System Benefits and Costs

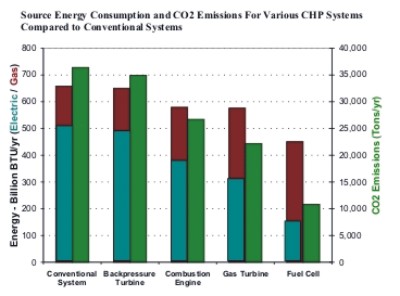

Many benefits are gained from the installation of CHP systems, including increased electrical grid stability due to distributed generation, reduced energy consumption, and reduced pollution, including CO2. Because they have no use for it, sixty to eighty percent of heat generated in power plants is dumped to rivers, lakes, reservoirs, or the atmosphere. In CHP, most of this heat that is otherwise required at the end-user site is captured. Energy reductions are also achievable in CHP systems because of the elimination of the transmission losses that exist in the centralized electricity distribution system.

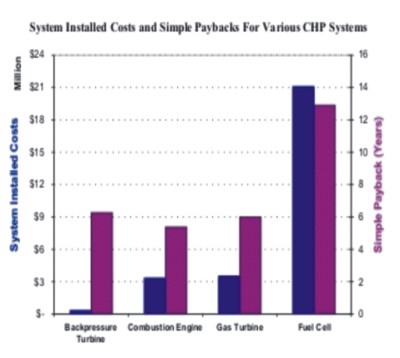

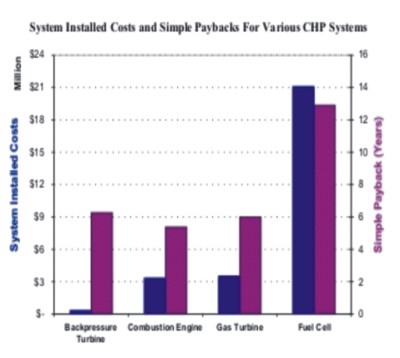

The added cost for CHP is essentially due to the electrical generating portion. There may be some reduced cost for the heating system, depending on the application. Operating costs are substantially insulated from volatile energy prices because CHP systems displace natural gas that is otherwise needed for generation of heat on site anyway.

Example

A year-round production facility with constant electric and gas loads around 5,000 kW and 1,500,000 therms per year, respectively, were compared with various CHP systems. The systems were sized to provide the full heating load at the facility, and the remaining electricity is still purchased from the utility.