To engineers, challenging the physical laws would seem against our religion. But hey, people try it all the time and a paradigm shift never hurt anyone, right? Plus, who is out there keeping physics on its toes?

(Almost) cooling for free

No matter where you are, there are typically times throughout the year when economizing, or “free cooling[1]”, is possible for commercial space conditioning, process cooling, and certainly data centers. Water-side economizing refers to cooling a liquid used for air conditioning (typically water or a coolant solution) with outside air rather than with conventional mechanical cooling equipment. Pumps (and maybe fans) will still have to be used, but enjoy the savings and good feeling knowing the compressor is not running.

The perpetual cooling loop (in a way)

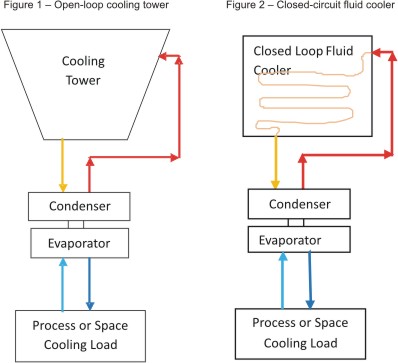

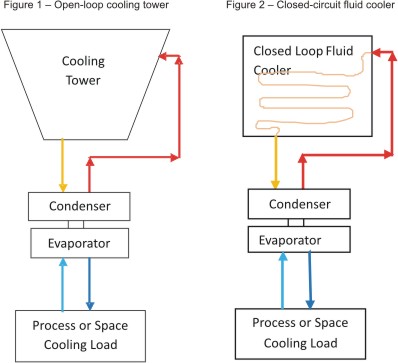

Hopefully there is a system in place that can at least provide free cooling. This system likely consists of either a cooling tower or a fluid cooler, which are used to reject heat from the process or building to the outside air. This could be set up in one of many configurations, but let’s look at a fundamental difference common to heat rejection equipment design: open-loop versus closed-circuit (or closed-loop).

Open-loop, Figure 1 – Condenser water is typically connected directly to the cooling tower or first passed through a heat exchanger connected to the cooling tower water loop (the latter not shown). The cooling tower water is exposed to the ambient air to provide cooling by evaporation. Cooling towers can be operated at low ambient temperatures, but by convention there are potential freezing issues: regular water exposed to sub-zero temperatures.

Closed-circuit, Figure 2 – The condenser water is typically coolant in this configuration and is passed directly through the fluid cooler. As the process coolant passes through the fluid cooler, it is never exposed to the ambient air. The primary benefit to this configuration is that it uses coolant, often a glycol solution, which avoids freezing issues or the need to have a supplementary heater or sump pump on the loop. This allows robust, “free-cooling” during the winter with less to worry about. Ahh, a perpetual cooling water loop![2] Fluid coolers also have the ability to consume less water and therefore have less scaling and fouling issues, which affect heat transfer effectiveness.

[1] Mostly free to the end-user but not per the First Law of Thermodynamics

[2] Nothing is perpetual except for change itself according to some: see the book of I Ching or the Second Law of Thermodynamics