Michaels Energy field engineers visit thousands of sites every year to either verify or measure a plethora of different equipment retrofits or controls additions. Customers and facility owners have questions about energy efficient equipment all the time. However, there are several technologies that are asked about more frequently than others. Today’s brief explains one of those; hot water reset controls for hot water (hydronic) space heating systems.

Traditional Controls

Most “traditional” hydronic systems have a centralized boiler plant. The boiler plant is coupled with circulating pumps that send the hot water throughout the facility to air handling units, baseboard heaters, cabinet heaters and other terminal equipment. The conventional wisdom was to heat the water to 180°F to ensure that enough heat could be transferred to the air through the heating coil during the peak heating season. However, that means heating the water to 180°F all year, or at least all heating season, even if it’s a moderate 50°F outside. This is similar to running a car engine in idle all the time, even though it’s going to stay parked in the garage for a while. Besides the obvious carbon monoxide risk, it’s not a good idea. In fact, boilers with advertised efficiencies in the mid-90s will perform in the mid-80s or lower at high water temperature.

Hot Water Reset Controls

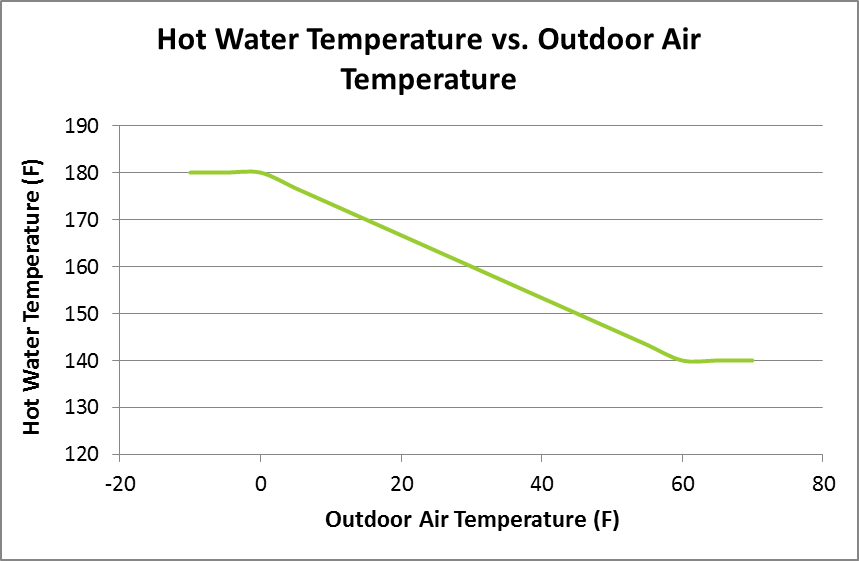

Establishing a hot water reset schedule allows the boiler to only heat the water to a designated set-point. This can be done several ways, but an easy example is to fit a linear adjustment based on the outdoor air temperature. As shown in the graph, as the outdoor air temperature warms, the temperature to which the hot water is heated gradually reduces from a maximum value to a minimum. In this example, the high 180°F is maintained when it’s very cold, less than 0°F. However, as the weather warms, the hot water temperature is adjusted downwards to 140°F once it’s 60°F outside.

This strategy assumes heating coils are appropriately sized to meet loads. For more aggressive control and savings, temperatures can be set lower. For example, move the entire temperature control curve lower by a few degrees. Consider other factors.

Simple Right?

In principle, hot water reset controls are as basic as the above example. However, there are many finer points that need to be addressed in order to optimize these types of controls. Boiler type, system heating needs, pumping efficiency, and pumping controls are all factors that can be tweaked to ensure the maximum reset of customer utility bills.