Capture the Heat You Paid For

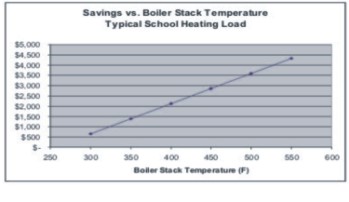

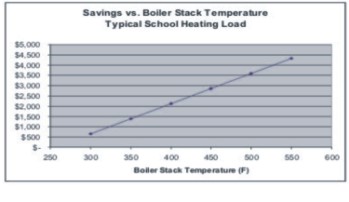

The largest heat loss from a boiler system escapes through the exhaust stack. Exhaust stack temperatures for conventional steam or hot water boilers are typically in the 350 to 500F range, and sometimes even higher than that. Any exhaust gas leaving the stack above boiler room temperature is a loss on the system – the higher the temperature, the greater the loss. But you can do something about it, in many cases with a fabulous return on investment! You can capture this heat and use it in your facility or processes with a stack gas economizer.

A consistent use for this captured heat on a steam system is for pre-heating boiler feed water, which normally enters the boiler at less than 212F. The boiler is almost always taking feed water so there is nearly a constant use for stack gas recovery when the boiler is operating. Other uses for captured stack-gas heat include boiler makeup water, manufacturing processes, service water heating, or space heating. Colder water will enable greater heat recovery; in some cases the stack temperature can be taken down to 100F.

A basic heat recovery system, or “boiler economizer”, consists of an air-to-water heat exchanger placed in the stack of the boiler exhaust. Heat is transferred from the exhaust gas to boiler feed water or other heating load.

Economizers are selected based on a number of parameters. Exhaust gas condensation is an issue and this and other selection criteria will be part of a future Brief . This Brief focuses on the potential energy savings.

The amount of savings depends on several items.

- The existing stack temperature (how much heat can be extracted)

- The cost of your boiler fuel

- The hours of operation of your boiler (more hours = more savings)

- Average boiler firing rate

- Economizer entering water temperature and flow rate

A rule of thumb is that for every 40F decrease in boiler stack temperature, there is an increase in boiler efficiency of 1%! Total improvements of 3-5% are typical. While this may not sound like a lot, it can translate to big savings and short paybacks.

Join the discussion One Comment