Some Background on Steam Boilers and Feedwater…

Steam boilers convert water into steam for space heating or processes, or both in some cases! The boiler feedwater is a combination of condensate returned and accumulated from the distribution network and fresh make-up water, which are pumped to the boiler and heated to make steam. Depending on the application, steam boilers may need to produce low pressure or high pressure steam. The steam pressure set point is typically constant, although it can vary based on what the steam is used for.

So What’s the Problem with Variable Speed Pumping of Feedwater?

Steam boilers need to build up enough pressure to meet temperature requirements of the loads and possibly to decrease piping sizes and first costs. This pressure can be substantial, in some cases over 150 psig – roughly five times the air pressure in your car tires! Even if the feedwater flow can vary, a substantial pressure boost must be overcome in order for the feedwater to even enter the boiler, requiring water pressure and thus flow to remain elevated. Recall the affinity pumping laws which essentially stipulate that as the pump speed is reduced, both flow and head pressure is reduced as follows:

- Head pressure (psig), H, varies by the square of the pump speed ratio R2/R1:

- Pump flow, Q, and pump speed, R, are linearly proportional:

These equations ONLY truly apply when the slightest pressure derived from the pump will produce flow, as in a garden hose. A feedwater pump is akin to adding air to your tires. There is no net flow into the tire until compressor pressure surpasses tire pressure – and so it is with feed water pumps and steam boilers.

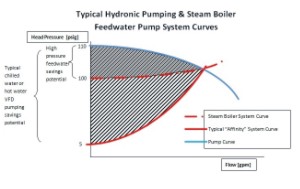

A reduction in feedwater pressure below steam pressure cannot occur in order for the steam boiler to function properly. This has a significant impact on energy savings derived from variable speed feedwater pumping. The chart demonstrates savings potential for both a 100 psig feedwater pump application and typical chilled water or heating hot water circulation pump – an “affinity” pump. Compared to a traditional chilled or hot water system, which has a similar system curve with much lower static head, the high static head of the feedwater system requires high horsepower, even at the lowest flows.

Are There Cases Where Variable Speed Feedwater Pumping May Pay Off?

If pressure can vary or if significant minimum pressure is not required, a VFD pump may achieve acceptable return on investment.