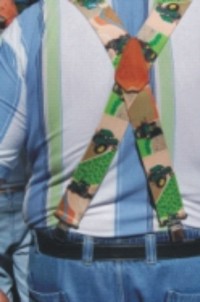

More is Good

Ever heard the saying “you can never have too much of a good thing”? Everyone wants more and when it comes to saving energy, you can never do too much. Or can you? When trying to create energy saving systems for LEED® design projects, some HVAC systems are designed with more components than they need. System designs with unnecessary components are known as “belt and suspenders” designs. If a designer has never worked with the system before, extra features or capacity are often included to make double, triple, and quadruple sure it will keep the building warm and/or cool. However, this is ultimately unnecessary if a good design has been produced.

Less is More

Supplemental Heating

Many times ground source heat pump systems will be designed to include a supplemental heat source, such as a boiler, for the water loop. This type of addition is installed to ensure that the system will meet the required heating loads and sometimes to prevent the circulating loop piping from freezing. In commercial buildings with a properly sized design, adding a boiler is not necessary as the ground heat exchanger is capable of providing sufficient heating capacity; especially when antifreeze is added. The argument often goes that antifreeze is expensive. Well a boiler isn’t free, especially when you have to pay to operate it. But, the argument is it won’t need to run. It’s just there for insurance. What?

On a recent retrocommissioning project, a ground source heat pump system incorporated a boiler “just in case” and water temperatures dropped to 60-65F in the coldest periods of the winter. We had to do a double take on that one. The ground heat exchanger was extremely deep where temperatures approach 70F or higher. With “freezing” temperatures such as these, it’s a good thing that boiler is installed!

Antifreeze in the form of propylene glycol may be expensive, but a cheaper and actually better solution that some heat pump manufacturers are recommending is ethanol, which has much better fluid pumping and heat transfer characteristics than conventional antifreeze.

Energy Recovery

Another common design error is to include an energy recovery ventilator (ERV) where it is not needed. For example, a gymnasium is rarely fully occupied so it typically requires very little ventilation air. When it is highly occupied, the people add considerable cooling load and the space will likely call for cooling via economizer, which bypasses the ERV, making it useless.

Balance

A properly designed system should have no need for any additional frills attached. During the design phase, designers should consider all possible loading situations in order to make sure the system meets its heating, cooling and ventilation demands, while not overcomplicating things.