I’ve got a “Super-Ultra-Quantum” chiller… what else is there?

The chiller itself is not the end-all/be-all of energy use in a chilled water system. Many factors should go into deciding the components of a chilled water system, one of which is whether to have an all primary chilled water system.

Primary/Secondary Systems

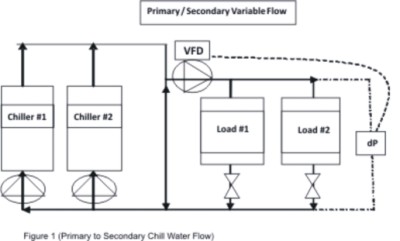

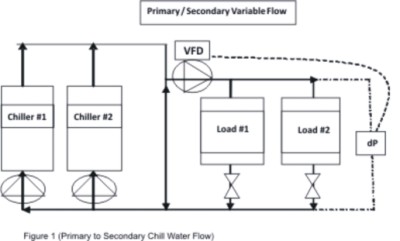

A few years ago, chillers were designed to operate with a specific flow rate. Chilled water pumping systems were designed with a primary chilled water circulating loop that continuously maintains a constant flow through the chiller. The secondary circulating loop(s) served the loads in the building. Pumps in the secondary loops pull the water they need from the primary loop and the rest bypasses the air handlers completely and is sent directly back to the chiller. This results in circulating excessive water that provides no cooling to the spaces. Moreover, the secondary loop in many designs meets varying cooling loads using three-way valves[1] for each air handler. Similarly, flow to the coil varies but excess flow is bypassed and the secondary pumps operate at constant flow.

A somewhat better approach is to at least vary the flow in the secondary loops with no bypass, using two-way valves[2]. This system is depicted in the figure. But this also wastes energy, even in the secondary loop pumping, and can cause other problems with control and energy waste – topics for another day.

[1] A three-way valve has one inlet and two outlets. Flow is split to the two outlets based on control signal to meet cooling loads. As cooling loads increase, less water is bypassed and vice versa.

[2] A two-way valve has one inlet and one outlet and obviously the flow in is equal to the flow out. However, there is no bypass and so as the cooling load varies, so does the flow the valve sees as does the pump see.

All Primary Systems

Because many new chillers are able to handle varying flows of chilled water, an all primary design can allow the flow of the water through the chiller to match the flow of the water required to meet the loads at the cooling coils. An all primary chilled water system uses pumps to circulate water from the chiller through the building and directly back to the chiller – no bypassing flow, anywhere.

A variable frequency drive can be installed for the circulating pump. The speed is controlled by differential pressure between the upstream to the downstream side of the cooling coils. For optimal performance, coil valves should be controlled to maintain a design outlet temperature. This minimizes pumping flow and maximizes the return water temperature, which in turn maximizes the efficiency of the chiller. To save even more energy, the differential pressure set point should be adjusted so that at least one cooling coil valve is almost wide open. There is no sense in maintaining design differential pressure when all the valves are pinching off flow.

Conclusion

Chillers are plugged into many types of systems, and to think the greatest whiz-bang chiller is the answer is probably missing the pie and only getting the meringue.