As a writer and talker[1], there are certain phrases and clichés I practically refuse to use. These include:

- Boots on the ground

- At the end of the day

- Low hanging fruit

- Thrown under the bus

- Kick the can down the road

Are there any psychiatrists, sociologists, social scientists, or psychologists in the audience to answer this question: why do people gravitate toward these phrases? Is it how they roll off the tongue?

Thrown under the bus. Have you ever seen anyone thrown under the bus? Even in a movie? How would you throw somebody under the bus? Is the bus stationary because throwing someone under a moving bus would be pretty difficult? Should the saying be “throw somebody in front of the bus”? Hey, I push people down the stairs, but I’m not sure how to advance to throw people under the bus!

What they really mean is:

- People in the field, on site, or in the theatre (of war)

- Most importantly

- Easy stuff

- Berated

- Procrastinate or stall

Of course, these terms are universal and used all the time in the energy efficiency business, but I want to move on to issues related with energy efficiency, especially in the core of what we do.

Building tune-up. Buildings are like cars in some ways and unlike cars in other ways. They are like cars in that anything built in the last twenty years has digital controls, and that means binary stuff – on/off, device works or does not work. Buildings are unlike cars in that they are not mass-produced, and the quality control is comparatively, absolutely horrible.

An engine tune-up would involve an old-fashioned engine working entirely on mechanical principles, including a carburetor. Nowadays, this is limited to small engines like those in chainsaws and lawnmowers. I can “tune” my chainsaw to idle fast enough to not stop running when I set it down. I can also adjust the fuel/air mix for power and efficiency. Real expert geeks can futz with the carburetor, and that’s what baby boomers and maybe younger car restorers did/do.

The winter car tune-up has gone by the wayside. Back in the days of the carburetor, starting a cold engine was an art. I remember lying in bed in the college dormitory with the window open in the middle of winter because the hand valve on the radiator in my room had been wire-drawn (leaked)… while listening to people trying to start their cars. They would crank the engine with the battery for minutes at a time until the battery eventually ran out of juice. I’m saying to myself “just stomp the gas pedal to the floor and hold it there until it fires and don’t let up until it starts to run continuously on its own (couple seconds)”. Instead they would tap the gas pedal repeatedly, hopelessly flooding the engine with too much fuel to start – until the battery was dead.

Nowadays, mechanics connect what is essentially a hand-held computer to a bundle of wires located in the cabin near the driver’s feet. The computer tells them what, if anything, is wrong. If something is wrong, typically a sensor failed. There is no tinkering with ratios of things, no screws to turn, or a “choke” to adjust. No “tune-up”.

Similarly, with buildings, if the device doesn’t work, there is no “tune-up”. Toss and replace. But more importantly, tune-ups infer the cause of the problem is fixed. This is not necessarily and not usually the case. For example, a boiler may be “tuned up” and running fine with the right fuel/air ratio. The problem is the water temperature is too hot. Efficient boilers are not efficient when running at excessive temperatures, and I mean only 140-180 degrees, which is generally cooler than the coolant coursing through your car’s engine. So, instead of the advertised 94% efficiency, the end-user is only getting 86% efficiency. This may look small, but it’s huge. We see this all the time when doing M&V, and I’m saying a program dedicated to fixing just this could capture substantial savings.

This leads me to the next point: solving underlying problems. With digital systems of the past quarter century, many, if not most, retro-commissioning opportunities exist because the name of the game for contractors is no complaints from the customer. A system may be controlled to handle the worst-case scenario, say humidity control, but the control setpoints are fixed all year. This wastes enormous amounts of both cooling (electricity) and heating (usually natural gas) throughout the year.

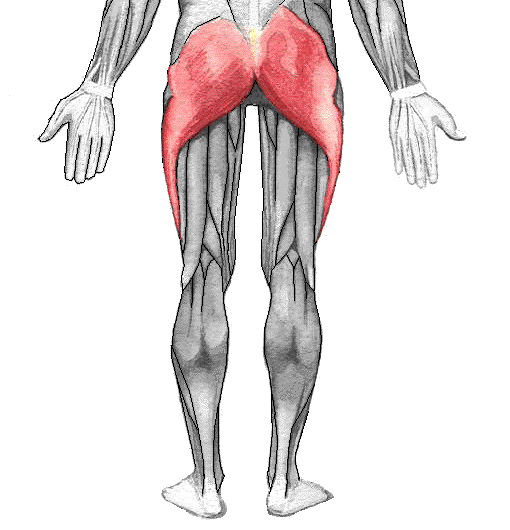

As a runner, I’ve had my share of problems and nagging injuries over the years. The location of the pain is almost never where the problem is. For example, I think I just discovered the reason why my adductor muscles (inside of thigh) were frying up. For a while I was stretching them like a banshee, to no avail. The problem? My glutes (butt muscles) weren’t firing. The glutes are large stabilizing muscles and over time, they may start to take a vacation and when they do, something else[2] is going to pay the price.

Buildings work exactly the same way. Air flow, not water temperature, may be the problem. Twenty-four-seven exhaust, not laziness, may be the reason air handlers are running all the time.

So, if by “tune-up” people think they can go in and reprogram programmable thermostats and other obvious things, they are mistaken. Customers generally know they shouldn’t have to run things 24/7, but they do because of a problem somewhere else. That takes knowledge, big picture expertise, and experience, like a physical therapist to fix for lasting results. Don’t call it a tune-up!

[1] Speaker, but that’s too generous for what emanates from my mouth.

[2] Typically, knees.