The big energy saving opportunities in a building are usually hidden from the unsuspecting field auditor. The obvious exception is lighting because it isn’t hidden! The hidden things are what go on behind closed doors in the dark. Yes, the salacious activity spawned by an out of control brain – the energy management system.

Similarly, nuggets flow across my desk, computer screen, and directly from people that feed topics of this Energy Rant. A few weeks ago, I stumbled onto data confirming my years-old assertion that tight fitting ductwork does not save energy, relative to in situ status quo. Being aware, like the auditor. Aha!

Also in past rants, I howled that letting large industrials and manufacturers opt out of energy efficiency programs was a crime against humanity. One such post was delivered a year ago. It featured Ghostbusters and crushed highways – a popular hit you might want to take a look at.

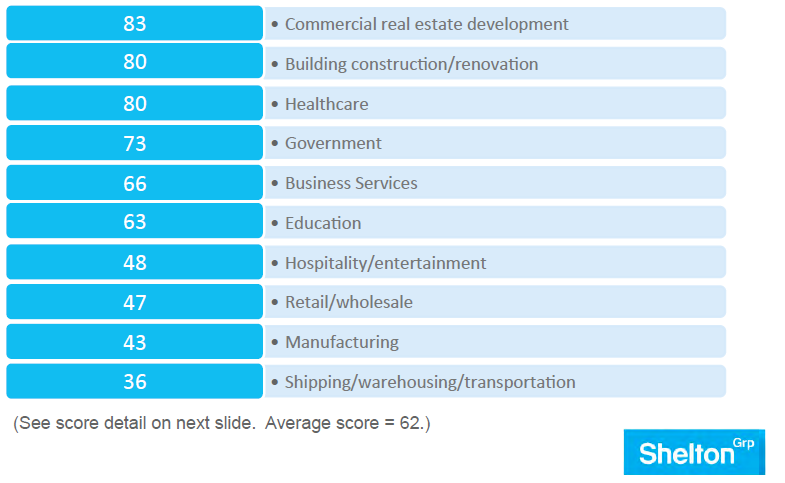

The results are in. As I was watching an AESP webinar performed by Suzanne Shelton of the Shelton Group, one of the slides she breezed through nailed this for me, although she did not call it out specifically. Let me backtrack just a little.

The presentation covered results of surveys of 401 large commercial and industrial customers across the US including a wide variety of:

- Sectors; hospitality, healthcare, education, etc.

- People; CEOs, CFOs, facility managers, etc.

- Number of customer facilities

- Size of facilities

- Geographic regions

The results covered things such as:

- What are important factors in your (surveyee) purchasing decisions?

- What systems including lighting, HVAC, water heating, etc., are you most interested in for efficiency?

- What have you actually done to make these systems efficient (i.e., anything)?

One of the slides (pictured on the left) showed results of engagement by sector.

Shipping and warehousing? They just have flickering dim light here or there. Why would they care about efficiency? They don’t use any. This puts manufacturing dead last! This is the dagger in that stack of bologna.

I should note that industrial customers made up the largest slice of the survey-sample pie.

So let’s retreat to statements from beneficiaries of the manufacturing lobby’s largess.

Eric Koch, R-Bedford (Indiana), says Hoosiers should be confident that industrial users will still engage in energy efficiency. “They have an incentive to be as efficient as possible – it’s their money,” Koch says. “And they have people working within the companies who are experts at energy efficiency.”

Eric, you have a problem.

Additional chutzpah from Indiana includes statements from Senator Merrit, who says. the next stage of energy savings was about to become too expensive. Industrial customers especially objected to being forced to pay for energy-efficiency programs that didn’t fit their highly specialized needs.

“They have found the utility programs to be of little value to them,” said Jennifer Terry, attorney for Indiana Industrial Energy Consumers, which represents 26 of the state’s largest manufacturing electricity customers. Terry also states the industrial group supports continuing to allow large users to opt out.

I must add that Ms. Terry could be correct that the programs are of little value to industrial users. Then fix the program! Hire an implementer that knows what they’re doing.

Indiana isn’t alone. I could provide a laundry list of statements and claims by politicians and industry groups from other states and provinces who say they’re good enough, smart enough, and doggonit, I don’t need you. Ontario regulators have even bought into the claptrap.

On the flip side of this coin we have smart industrial customers embracing energy efficiency and EE programs. When Green Bay Packaging’s upper management caught wind of EE programs rolling back in for their Maryland facilities, they rushed to sign up. “Of course, I was like, ‘Count me in!'” said Tyson Aschliman, the plant’s general manager. According to this article in the Baltimore Sun, that program focuses on companies making products for a simple, weighty reason: Energy eats up big chunks of most manufacturers’ budgets. Organizers see reducing that expense as one way to keep companies around in an era scarred by moves and shutdowns.

“Costs are such a key competitive issue that when we’re saving it through energy efficiency, we’re giving manufacturers a competitive advantage,” said Mike Galiazzo, president of the Regional Manufacturing Institute of Maryland, which runs the program. “And every manufacturer has money sitting on the table. Everyone.”

Everyone.

The other interesting thing is that smart utilities, which aren’t even required to run programs, are offering energy efficiency assistance to their largest customers as a service. This is occurring in the south, to which manufacturing has fled, from rust belt states.

Smart utilities, like those in the south and even overseas in places like Australia and New Zealand, understand if they want to keep their big power users, either from jumping to other providers or keep them in business, they will help them prosper. Since energy is such a major cost of manufacturing, energy efficiency services are a slam dunk.

Ignorant Midwest states[1]: get it?

[1] Not to be confused with smart Midwest states.