Last week we revealed the five priorities of saving energy:

- Shut it off

- Slow it down, set it back (temperature, etc.)

- Reduce waste

- Retrofit or replace with efficient equipment

- Don’t be stupid

Speaking of don’t be stupid, if you didn’t read last week’s post…

In this case, “don’t be stupid”, is not easy – like telling a fighter pilot or neurosurgeon not to be stupid. But this is why I write. If it were easy, everyone would do it, and I wouldn’t have a job.

Baby Steps

To recap last week’s post, energy used for processes including refrigeration, air conditioning, compressed air, and more, should take the smallest possible increment of energy to do the job. Also, adding energy in steps is another way to improve efficiency. The following is one more example of modern design.

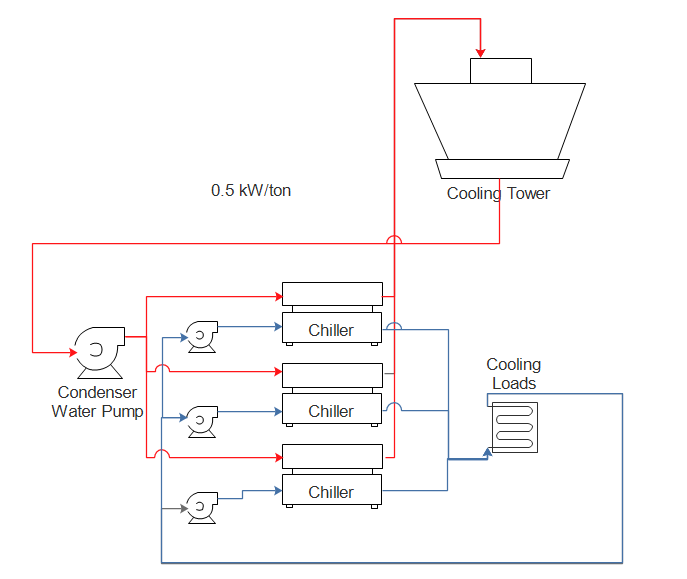

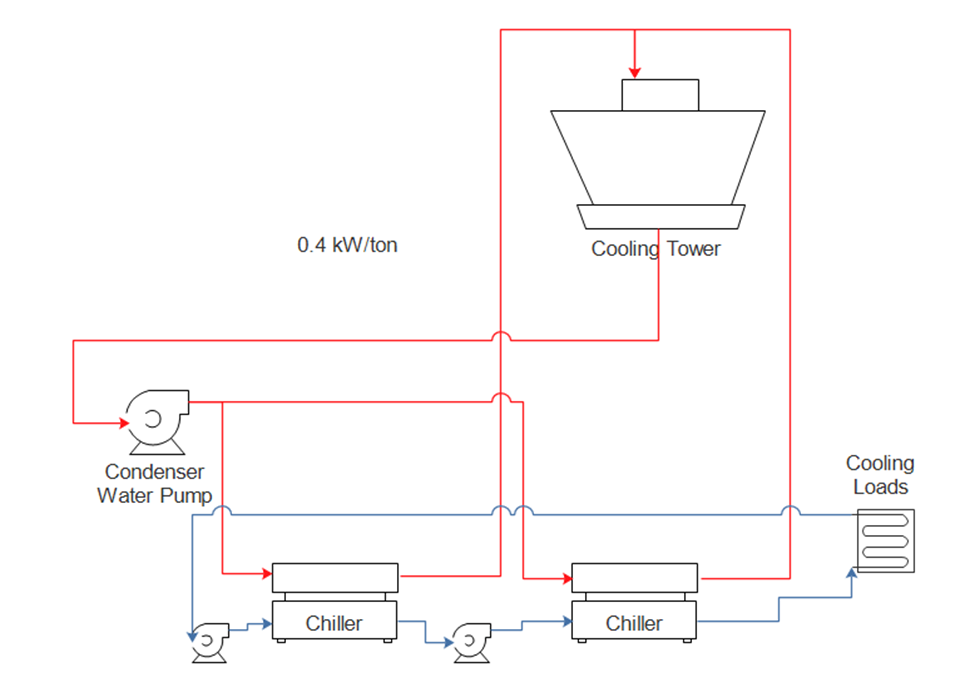

The first cartoon features a typical chilled water plant that may serve a hospital or process cooling for food processing. The blue lines represent chilled water for cooling, and the red lines represent warm condenser water for heat rejection to outdoors. If you Google “chiller configuration” you will see many cartoons like this one, but mine is special because I made it for you, my beloved readers!

The lineup, as shown, typically has one chiller idle for backup, while the other two handle the load. If space cooling is the load, only one chiller may be needed most of the time, and two are needed when it is really hot outdoors.

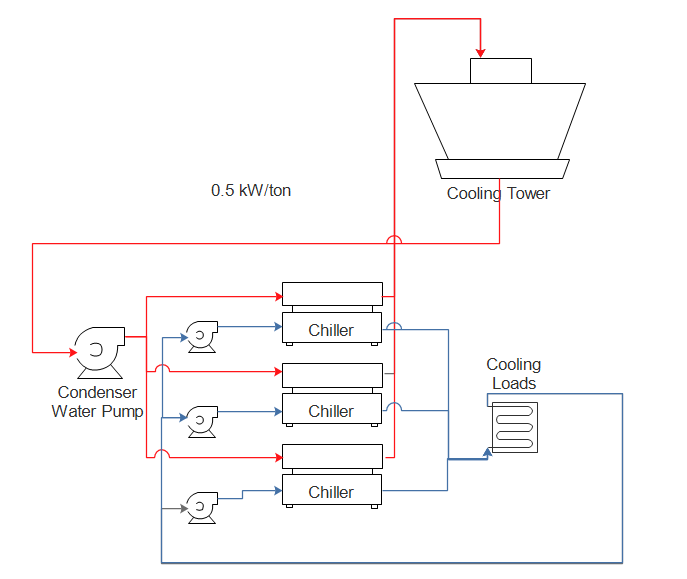

Want a better design? Glad you asked! The second cartoon, again handmade by me for you, shows a more efficient design with chillers in series rather than parallel, which has been the standard design for one million years. (I left the third chiller out to clear the clutter, but just pretend it is still there)

The efficiency of the plant may improve from a standard chiller efficiency of 0.5 kW per ton to 0.4 kW per ton. Not much? That’s 20% folks – for doing NOTHING more than thinking outside the box a little.

What’s a ton? It is a measure of cooling capacity. A typical home has a load of three tons. Therefore, per above, three tons would require 1.5 kW. What is 1.5 kW? A hair dryer at full blast. Yes, you can cool your home with the same power draw as a hair dryer nearly all season. Dazzle the family members with that factoid.

One last thing before moving on: simple configuration changes above are everywhere. (EVERYWHERE) You better believe that 99% of system upgrades in an industrial or large commercial facility will involve simply plopping in another chiller when more capacity is needed, or replacing a chiller one for one if a new one is needed.

What an epically monumental blown opportunity. Plan, man. Plan!

Big is Beautiful

Moving on. If the device in a system does not consume energy, make it BIG. What am I talking about? See the cooling tower above? That is a big heat exchanger. The bigger it is, the better. A heat exchanger uses no energy. Sure, there is typically a fan on such a tower, but control it with a variable frequency drive.

Larger heat exchangers transfer more heat for less energy. That is their purpose: transferring heat. In fact, chillers and air conditioners of varying efficiencies typically have different size non-moving parts (heat exchangers). The moving parts (compressors) may be the same in a 0.4 kW per ton as the compressor used for a less efficient 0.6 kW per ton chiller.

For a refresher, refrigerant under vacuum may boil at 35 degrees F (35F). Chilled water comes back to the chiller at 55F. Heat flows from high-temperature 55F to low temperature 35F through the chiller’s heat exchanger, which separates refrigerant from chilled water.

For the Love of Pete, Use It!

Big heat exchangers and multiple heat exchangers are expensive, but you would be surprised that once they are bought and paid for, they are under-utilized. It reminds me of when I was a kid, and I drove my mother nuts. That is our job, right? When I would get new clothes she would say, you should wear out your old stuff and keep the new stuff nice. What? Mom. What is the point of that? See why I’m on the prior decade’s fashion trends to this day?

For heat rejection, there may be multiple cooling towers or refrigeration condensers in parallel, not unlike the first chiller configuration shown above. Use all that you can all the time. That means at part load (99% of the time), pump condenser water over all the cooling towers; use all the refrigeration condensers you can.

Remember last week – the objective of compressors is to move pounds of air or refrigerant, and not volume. Using more condenser area (see last week’s post) lowers the head pressure, allowing more pounds to flow for a given power input.

Efficient!

Design in Series, Operate in Parallel

We already established that it’s better to consume energy in series – baby steps. For heat exchangers, we want to use them all. They are configured in parallel. Use them all!

New variable speed equipment, like chillers and compressors, have very efficient low capacity operation. Therefore, it will probably be more efficient to operate two units in series rather than just one, even at very low loading points. If you need assistance, I can probably find an engineer who can help.